- Product Details

- {{item.text}}

Quick Details

-

Power:

-

18.5-550

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

47-557t

-

Warranty:

-

12 Months

-

Feeding size:

-

10-80mm

-

Diameter range:

-

1-5m

-

Spares Parts:

-

supply for one year freely

-

Application:

-

cement,limestone, various ores and other materials

-

Production Year:

-

2015

-

Manufacturing Experience:

-

60 years

-

Installation:

-

Under our engineer's guide

-

Calcination temperature:

-

1000-1350°C

-

Rotating speed:

-

0.36-3.9rpm

-

Capacity:

-

2-160t/h

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ZK

-

Voltage:

-

400V

-

Power:

-

18.5-550

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

47-557t

-

Warranty:

-

12 Months

-

Feeding size:

-

10-80mm

-

Diameter range:

-

1-5m

-

Spares Parts:

-

supply for one year freely

-

Application:

-

cement,limestone, various ores and other materials

-

Production Year:

-

2015

-

Manufacturing Experience:

-

60 years

-

Installation:

-

Under our engineer's guide

-

Calcination temperature:

-

1000-1350°C

-

Rotating speed:

-

0.36-3.9rpm

-

Capacity:

-

2-160t/h

-

Certification:

-

ISO

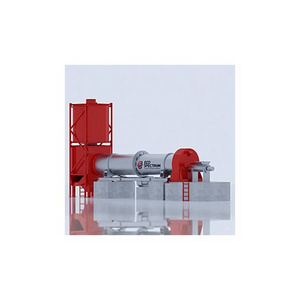

Rotary incinerator is a widely used incineration equipment in the field of international industrial waste treatment, its market share in the field of industrial waste incineration is really high. As a specific area for burning hazardous wastes , the rotary incinerator has wide adaptability to complex industrial waste and medical waste, and it’s stable and convenient to operate, of course, the equipment maintenance is simple, and so on. Therefore, it is the most widely used in the field of international hazardous waste incineration. It is a reliable and effective means to realize the harmless, reduction and recycling of wastes.

Application:

It is widely used in the field of industrial waste, medical waste, municipal solid waste, and so on.

Applicable material:

Hazardous waste, sludge waste, oily sludge, industrial waste, PVC material, medical waste, municipal waste, and so on.

2.Structure of Rotary Kiln Waste Incinerator

The rotary kiln is mainly composed of a transmission device, a support device, a supporting wheel, a supporting device, a cylinder body, a kiln head, a kiln end and a sealing device, etc.

1. Kiln flue chamber

2. Kiln seal

3. Preheating zone

4. Girth gear

5. Tyre

6. Transition Band

7. Electric Machinery

8. Reducer

9. Pinion

10.Roller

11.Burning zone

12.Cooling zone

13. Kiln hood

3.Working Principle of Rotary Kiln

Rotary kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the kiln rotates, material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing. Hot gases pass along the kiln, sometimes in the same direction as the process material (co-current), but usually in the opposite direction (counter-current). The hot gases may be generated in an external furnace, or may be generated by a flame inside the kiln. Such a flame is projected from a burner-pipe (or “firing pipe”) which acts like a large bunsen burner. The fuel for this may be gas, oil, pulverized petroleum coke or pulverized coal.

4.Technical Parameters of Rotary Kiln

|

Hazardous waste rotary kiln for waste incineration φ2.6m*13.2 technical parameter. |

|

|

Inner diameter of shell 2600mm |

Shell length 13200mm |

|

Downstream arrangement, that is, the direction of material flow is consistent with the direction of smoke flow, the angle of the kiln body is 1.5 degrees. |

|

|

Variable frequency speed control of rotary kiln |

0.1-2.2r/min |

|

Drive mode |

Single side gear drive |

|

Main Motor |

30kw |

|

Kiln temperature:850-1200 degree |

Surface temperature of kiln shell: 180 degree |

|

Expansion mode |

Linear free expansion at both ends |

|

Total equipment weight |

approx. 54.5t |

|

Customized waste incineration rotary kiln can be provided according to the customers' different industries |

|