- Product Details

- {{item.text}}

Quick Details

-

Max. Spindle Speed (r.p.m):

-

3000 r.p.m

-

Max. Weight of Workpiece(kg):

-

800

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

7.5/11

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

240 mm

-

Travel (Z Axis)(mm):

-

540 mm

-

Place of Origin:

-

Shandong, China

-

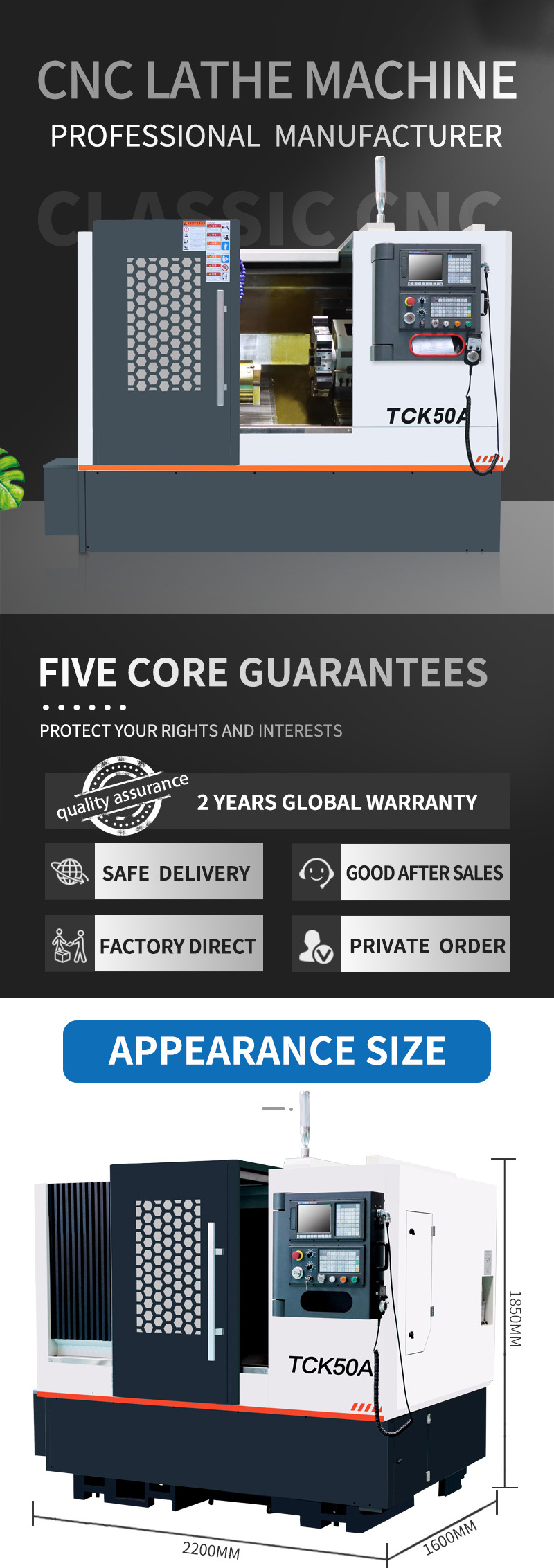

Dimension(L*W*H):

-

2600*1850*2000mm

-

Brand Name:

-

Classic

-

Model Number:

-

TCK50A

-

Voltage:

-

380V

-

Weight (KG):

-

3000

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

24 months

-

CNC or Not:

-

CNC

-

Product type:

-

Slant Bed Turning Center

-

Name:

-

High Precision CNC Lathe Machine

-

Product name:

-

CNC Lathe Mechine

-

Automatic Grade:

-

Automatic CNC Turning Machine

-

Model:

-

TCK50A CNC Lathes

-

Application:

-

Industrial Equipment

-

Control system:

-

GSK SIEMENS FANUC KND GUNT

-

Chuck:

-

3 Jaw Chuck

-

Product Keywords:

-

Cnc Milling Machine 3 Axis

Quick Details

-

Type:

-

Horizontal

-

Max. Length of Workpiece (mm):

-

350/500

-

Year:

-

2022

-

Max. Spindle Speed (r.p.m):

-

3000 r.p.m

-

Max. Weight of Workpiece(kg):

-

800

-

Width of bed (mm):

-

400 mm

-

Spindle Motor Power(kW):

-

7.5/11

-

Max. Turned Length (mm):

-

500

-

Travel (X Axis)(mm):

-

240 mm

-

Travel (Z Axis)(mm):

-

540 mm

-

Place of Origin:

-

Shandong, China

-

Dimension(L*W*H):

-

2600*1850*2000mm

-

Brand Name:

-

Classic

-

Model Number:

-

TCK50A

-

Voltage:

-

380V

-

Weight (KG):

-

3000

-

Marketing Type:

-

New Product 2022

-

Warranty of core components:

-

24 months

-

CNC or Not:

-

CNC

-

Product type:

-

Slant Bed Turning Center

-

Name:

-

High Precision CNC Lathe Machine

-

Product name:

-

CNC Lathe Mechine

-

Automatic Grade:

-

Automatic CNC Turning Machine

-

Model:

-

TCK50A CNC Lathes

-

Application:

-

Industrial Equipment

-

Control system:

-

GSK SIEMENS FANUC KND GUNT

-

Chuck:

-

3 Jaw Chuck

-

Product Keywords:

-

Cnc Milling Machine 3 Axis

Products Description

Product Application

This machine is mainly used for processing various shaft, disk parts, turning can be all kinds of screw thread, arc, cone and plane of internal and external surface can satisfy the ferrous and non-ferrous metals the speed requirement of high-speed chip. Suitable for cars, motorcycles, electronics, aerospace, military industry and other industries to high efficiency, large quantity and high precision of parts processing Machining precision can reach level 7.

This machine is mainly used for processing various shaft, disk parts, turning can be all kinds of screw thread, arc, cone and plane of internal and external surface can satisfy the ferrous and non-ferrous metals the speed requirement of high-speed chip. Suitable for cars, motorcycles, electronics, aerospace, military industry and other industries to high efficiency, large quantity and high precision of parts processing Machining precision can reach level 7.

|

SPECIFICATIONS

|

Units

|

TCK36A

|

TCK46A

|

TCK50A

|

|

Swing over bed

|

mm

|

360

|

460

|

560

|

|

Swing over cross slide

|

mm

|

170

|

170

|

260

|

|

Distance between centers

|

mm

|

300

|

350

|

350/500

|

|

Spindle bore

|

mm

|

48

|

56

|

66

|

|

Bar capacity

|

mm

|

40

|

45

|

55

|

|

Spindle speed steps

|

-

|

Stepless

|

Stepless

|

Stepless

|

|

Spindle nose type

|

-

|

A2-5

|

A2-5

|

A2-6

|

|

Spindle speed

|

rpm

|

4000

|

3500

|

3000

|

|

Turret/tool post

|

-

|

63-8T/12T

|

80-8T/12T

|

100-8T/12T

|

|

X axis travel

|

mm

|

310

|

240

|

240

|

|

Z axis travel

|

mm

|

350

|

400

|

400/450

|

|

X axis motor torque

|

N.m

|

6

|

7.5

|

7.5/10

|

|

Z axis motor torque

|

N.m

|

6

|

7.5

|

7.5/10

|

|

Main spindle motor

|

kw

|

3.7

|

5.5

|

7.5/11

|

|

Hydraulic tailstock quill dia.

|

mm

|

65

|

70

|

70

|

|

Hydraulic tailstock quill taper

|

-

|

MT4

|

MT5

|

MT5

|

|

Hydraulic tailstock travel

|

mm

|

220

|

200

|

200/450

|

|

Hydraulic tailstock quill traverse

|

mm

|

50

|

80

|

80

|

|

Guide rail type

|

-

|

Slant bed linear rail

|

Slant bed linear rail

|

Slant bed linear rail

|

|

Machine weight

|

kg

|

2100

|

2600

|

2800/3000

|

|

Overall dimension

|

mm

|

2100*1450*1700

|

2500x1700x1890

|

2500x1700x1890

|

Standard Accessories: Optional Accessories:

1、Taiwan higher accuracy linear guide ways 1. NC System: KND1000Ti, Fanuc Oi Mate-T

2、Taiwan ball screw 2. Main Motor: Servo 11/15 KW

3、Hydraulic magazine 3. Turret: 8 station electric turre

4、Taiwan hydraulic chuck 4. Chuck: 8″Non-through hole hydraulic chuck

5、Hydraulic tailstock 5. 8″Non-through hole hydraulic chuck (Taiwan)

6、Taiwan hollowed rotary cylinder 6. 8″through hole hydraulic chuck(Taiwan)

7、station hydraulic turret 7.10″Non-through hole hydraulic chuck

8. 10″through hole hydraulic chuck(Taiwan)

9.Chip conveyor

10.Steady Rest

11.Without tailstock

12.Inverter 11 KW

1、Taiwan higher accuracy linear guide ways 1. NC System: KND1000Ti, Fanuc Oi Mate-T

2、Taiwan ball screw 2. Main Motor: Servo 11/15 KW

3、Hydraulic magazine 3. Turret: 8 station electric turre

4、Taiwan hydraulic chuck 4. Chuck: 8″Non-through hole hydraulic chuck

5、Hydraulic tailstock 5. 8″Non-through hole hydraulic chuck (Taiwan)

6、Taiwan hollowed rotary cylinder 6. 8″through hole hydraulic chuck(Taiwan)

7、station hydraulic turret 7.10″Non-through hole hydraulic chuck

8. 10″through hole hydraulic chuck(Taiwan)

9.Chip conveyor

10.Steady Rest

11.Without tailstock

12.Inverter 11 KW

Detailed Images

Details Display

Recommend Products

Company Introduction

FAQ

1. What is the payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight . When we receive the advance payment, we will start to make production.when the machine is ready , we will take pictures to you.after we got your balance payment. we will send the machine to you.

2.

What CNC system do you use?

A: FANUC, SIEMENS, MISTSUBISHI, LNC,SYNETC,GSK,etc. It depends on your choice.

3.How can I choose the most suitable machines ?

A: Please let us know your machining demand or machine size ,we can choose the best model for you ,

or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

or you can choose the exact model by yourself. You can also send us the products drawing ,we will choose the most suitable machines for you .

4. What is your trade terms?

A : FOB, CFR,CIF or others terms are all acceptable.

5. What is your minimum order quantity and warranty?

A: MOQ is one set, and warranty is one year.but we will offer lifetime service for machine.

6. What is the package of the machines?

A: The machines standard packed by iron pallets with plastic films

Contact Us

Hot Searches