- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

PUREPATH

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

used oil to diesel machine

-

Function:

-

Diesel Distillation Machine

-

Raw material:

-

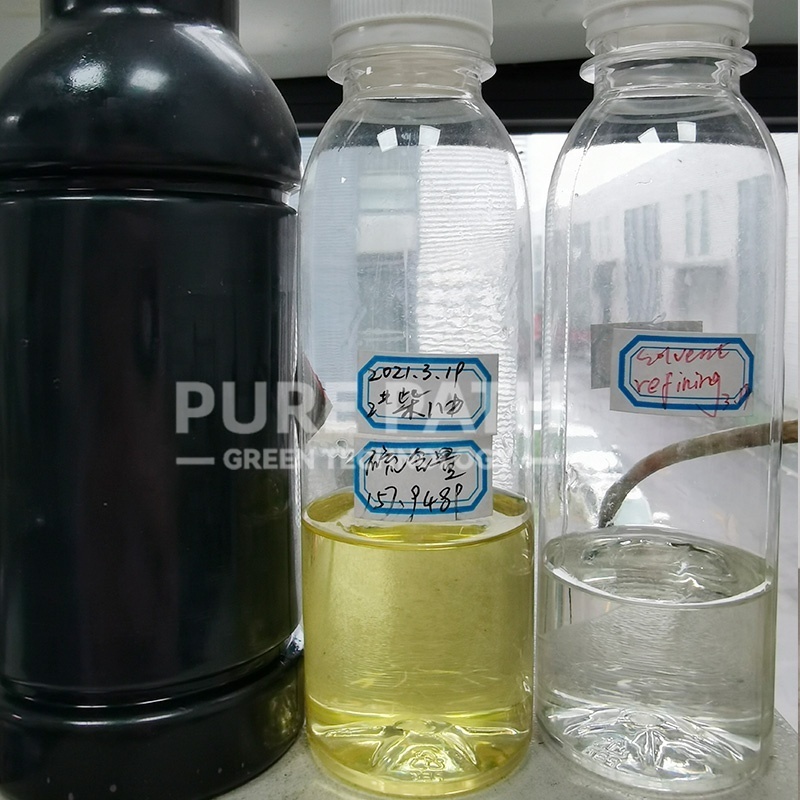

Waste Lube Oil/Pyrolysis oil

-

End product:

-

80-93% Diesel

-

Advantages:

-

Fully Continuous

-

Structure:

-

Genuine Complete continuous distillation

-

Technology:

-

Exclusive catalytic distillation

-

Working temperature:

-

30~460 ℃

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE&ISO

Quick Details

-

Applicable Industries:

-

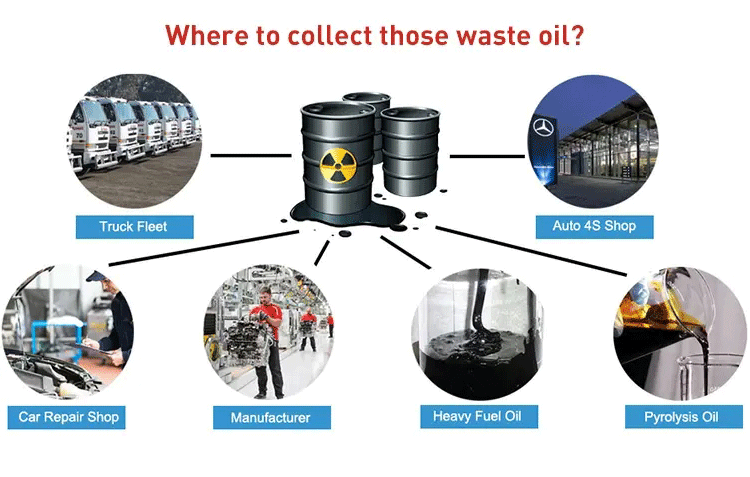

waste oil to diesel recycling distillation plant, Refinery, waste oil recycling

-

Marketing Type:

-

Hot Product 2024

-

Flow:

-

5-200 TPD

-

Place of Origin:

-

Chongqing, China

-

Brand Name:

-

PUREPATH

-

Voltage:

-

220~415V

-

Power:

-

As Required

-

Dimension(L*W*H):

-

As Required

-

Weight:

-

100000 kg

-

Application:

-

used oil to diesel machine

-

Function:

-

Diesel Distillation Machine

-

Raw material:

-

Waste Lube Oil/Pyrolysis oil

-

End product:

-

80-93% Diesel

-

Advantages:

-

Fully Continuous

-

Structure:

-

Genuine Complete continuous distillation

-

Technology:

-

Exclusive catalytic distillation

-

Working temperature:

-

30~460 ℃

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE&ISO

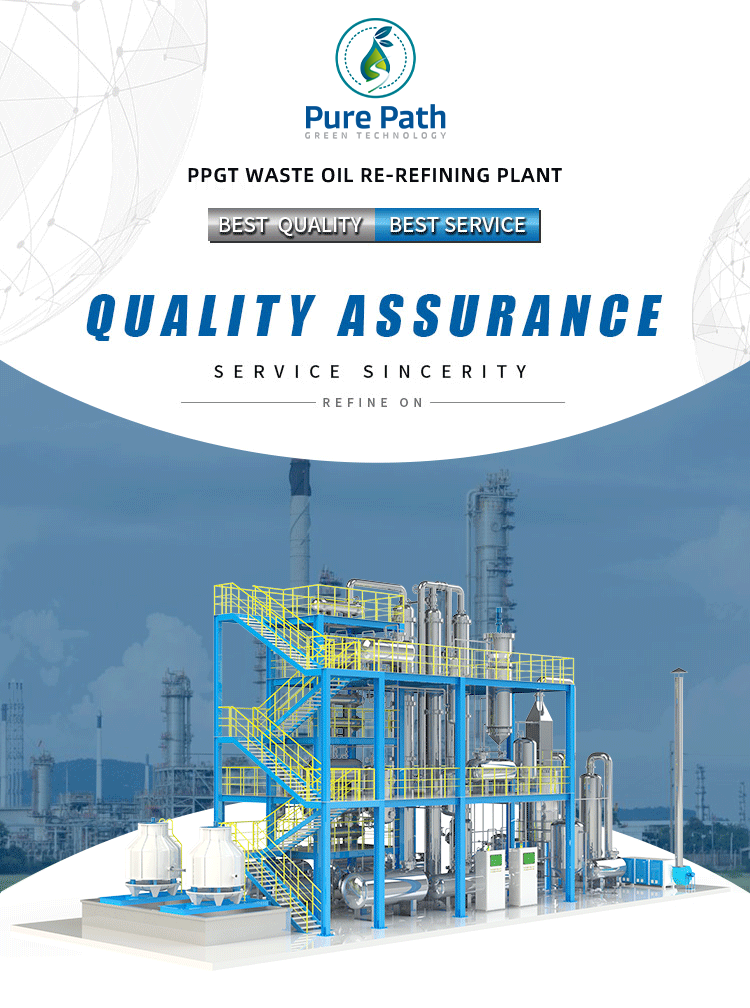

PLC Monitoring Countinuious Waste Engine Oil Recycling Distillation Plant To Diesel

Waste oil is used and contaminated by physical or chemical impurities, such as tyre pyrolysis oil, plastic pyrolysis oil, fuel oil, used engine oil, raw oil, waste washing oil, heavy oil etc. If they are not properly disposed, they will pollute the environment seriously. As the oil resources decrease, oil price is rising continuously. So there is an urgent need for an alternative of oil resources. Based on the current situation, the VP-LP Waste Oil Distillation to Diesel Plant is launched in the market to improve the environment, help relieving energy crisis as well as creating profits.

| Model No. | VP-LP-1 | VP-LP-2 | VP-LP-3 | VP-LP-4 | VP-LP-5 | VP-LP-6 | VP-LP-7 | VP-LP-8 |

| Items. | ||||||||

| Process Capacity MAX. | 2 TPD | 5 TPD | 10 TPD | 15 TPD | 20 TPD | 30 TPD | 50 TPD | 100 TPD |

| Heating Power | 17KGS LPG/20KGS FUEL OIL/230KWH/PER TON OF WASTE OIL | |||||||

| Power Consumption | 25KWH PER TONS OF WASTE OIL | |||||||

| Working Pressure | Atoms. pressure | |||||||

| Heating Method | Fuel Oil/Natural Gas/LPG/Electricity | |||||||

| Heating Temp. | 30-420℃ | |||||||

| Voltage | 220/380/415V 50/60HZ | |||||||

| Noise | ≤60dB | |||||||

Vpure (Chongqing) Petroleum Engineering Technology Co., Ltd. (the Vpure) was founded in 2007 and headquartered in Jiulongpo, Chongqing, China. Vpure owns its unique engineers team to provide designs and manufactures complete, turnkey, skid mounted systems which recover near virgin API group I, API group II base oil and ultra low sulfur commerical standard diesel from waste lubricants. Vpure has been testing, engineering, designing, fabricating, installing and operating waste oil re-refining and distillation systems since its inception. Customized production plants also includes equipment such as desulfurization, decolorization and machine oil purifier for diesel and base oil. Our mission is to facilitate environmental restoration, resource recovery and pollution reduction through innovative technologies and design, construction, and operation of affordable state-of-the-art waste recovery systems.