2. Lab rod mill is widely applied in labs for processing and fine grinding of artificial placer materials and ores in metallurgical, new building materials,cement,silicate, chemical, light, coal, water conservancy, electric power,glass ceramics, agricultural and geological industries.

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Lab Rod Mill

-

Application:

-

Stone Powder Grinding

-

The Machines classification:

-

Granding Mill Machine

-

Installation:

-

Engineer's Guide

-

Quality:

-

China Standard

-

Voltage:

-

380V

-

Usage:

-

Grinding Ores

-

Speed(r/min):

-

120

-

Advantages:

-

High Efficiency

-

After sale service:

-

Techniacal Support

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

wkd

-

Weight:

-

90 KG

-

Product name:

-

Lab Rod Mill

-

Application:

-

Stone Powder Grinding

-

The Machines classification:

-

Granding Mill Machine

-

Installation:

-

Engineer's Guide

-

Quality:

-

China Standard

-

Voltage:

-

380V

-

Usage:

-

Grinding Ores

-

Speed(r/min):

-

120

-

Advantages:

-

High Efficiency

-

After sale service:

-

Techniacal Support

Product Overview

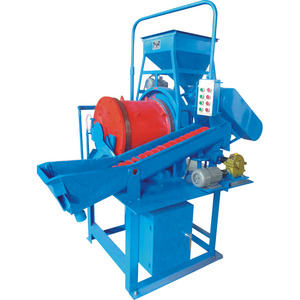

Laboratory Rod Ball Mill

XMB series rod ball mill is an efficient laboratory grinding equipment for wet grinding of ore or other materials. Steel balls can be used as grinding medium instead of steel rods. In rod grinding operation, particle sizes of final product are relatively uniform and ore overgrinding can be eliminated. Generally speaking, lab rod mill is commonly used as a grinder for mineral feasibility study and for heavy concentrate reduction.

FEATURES AT A GLANCE

Application

1.Laboratory Rod Mill is the key equipment for mineral ores grinding after the crush process in the lab, it can work with flotation cells, magnetic separators, shaking table and other equipments to make ore dressing test.

Work Operational Principle

The nodular graphite iron drum is connected with the big belt wheel by screw bolt. The one end of drum is open, and the other end hollow trunnion. Both ends are withstood by a pair of support and base bearing. The base bearing seat and support frame are mounted on support frame which can rotate in 180°.

The support plate are mounted on the frame with two bearing seat. The slewing ring can rotate 22.5°, 67.35°and 90° left and right from horizontal through control handle and alignment plate, so that ore loading, discharging, rod taking out, and rustproof fluid filling can be accomplished.

The right end of the drum is with ore feeding stopper, the left end with ore discharging cap, when the rod mill is working, tighten the screw bolt in a clockwise direction with a special wrench until the rubber gasket in the discharge cap tighten the screw bolt three or four turns, the cap withdraw outside 6~10mm, and without taking the cap away, the ore can be discharged. The discharge end is coupled with slurry collecting cover, so that the slurry splash phenomenon can be avoided completely.

PRODUCT SPECIFICATIONS

|

Model

|

|

XMB160*200

|

XMB240*200

|

XMB240*300

|

|

|

Shell Diamter*Length&Width(mm)

|

|

160*200

|

240*200

|

240*300

|

|

|

Volum(L)

|

|

4.02

|

7.5

|

13.57

|

|

|

Grinding Capacity(G)

|

|

300-800

|

500-1000

|

1000-5000

|

|

|

Feeding Size(MM)

|

|

-2

|

-2

|

-3

|

|

|

Output Size(MM)

|

|

-0.074

|

-0.074

|

-0.074

|

|

|

Shell Rotate Speed(R/Min)

|

|

120

|

110

|

96

|

|

|

Motor

|

Power (KW)

|

0.25

|

0.55

|

0.55

|

|

|

|

Rotate Speed(R/Min)

|

1400

|

1390

|

1390

|

|

|

Overall Size(MM)

|

|

1052*530*1160

|

1052*615*1160

|

1052*615*1160

|

|

|

Weight(KG)

|

|

90

|

155

|

160

|

|

Details Images

SIMILAR PRODUCTS

Hot Searches