- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

110/120/220/380 can be customized

-

Dimension(L*W*H):

-

150*90*120MM

-

Weight:

-

120 kg

-

Application:

-

Sawdust pellet making machine

-

Raw material:

-

Rice Peanut Husk Stove Pellet Manufacturer Efficiency Straw Pellet

-

Function:

-

Biomass fuel pellet maker

-

Processing Types:

-

Smal wood pellet making machine

-

Widely exported to:

-

Malaysia

-

Feature:

-

Poultry Feed Pelleting Plant

-

Pellet size:

-

2-18mm

-

Spare parts:

-

Roller

-

Advantage:

-

Low Energy Consumption

-

Suit for:

-

Cow.sheep.goose.duck.chicken.etc

Quick Details

-

Max. Capacity:

-

3 ton/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yize

-

Voltage:

-

110/120/220/380 can be customized

-

Dimension(L*W*H):

-

150*90*120MM

-

Weight:

-

120 kg

-

Application:

-

Sawdust pellet making machine

-

Raw material:

-

Rice Peanut Husk Stove Pellet Manufacturer Efficiency Straw Pellet

-

Function:

-

Biomass fuel pellet maker

-

Processing Types:

-

Smal wood pellet making machine

-

Widely exported to:

-

Malaysia

-

Feature:

-

Poultry Feed Pelleting Plant

-

Pellet size:

-

2-18mm

-

Spare parts:

-

Roller

-

Advantage:

-

Low Energy Consumption

-

Suit for:

-

Cow.sheep.goose.duck.chicken.etc

Small Wood Sawdust Grass Alfalfa Pellet Granule Machine to Make Corn Stalk Straw Hay Biomass Wood Pellets Making Machine Price

Description of Small Wood Sawdust Grass Alfalfa Pellet Granule Machine to Make Corn Stalk Straw Hay Biomass Wood Pellets Making Machine Price

Widely used to produce feed pellets and biomass fuel pellets. Wide Application Range: Any kind of biomass materials containing wood fiber, such as peanut shell, bagasse, castor shell, straw, sawdust, coffee grounds, rice husk, sunflower shell, cotton stalk, tobacco residue, leaf mustard stalk, bamboo, jute residue, tea residue, wheat-straw, palm shell, bean shell, coconut shell, dregs of decoction, and wood waste, etc.

Product Description

Features of Small Wood Sawdust Grass Alfalfa Pellet Granule Machine to Make Corn Stalk Straw Hay Biomass Wood Pellets Making Machine Price

1. the wood pellet machine can press biomass such as sawdust, straw and rice husk pellet.

2. adopting coldpressing molding technology, polishing process. Beautiful appearance, compact structure.

3. using special high quality materials and advanced even shaft driving device, the key components are high quality alloy steel with wear-resisting material, using German vacuum heat treatment furnace, will span the working life to five to seven times.

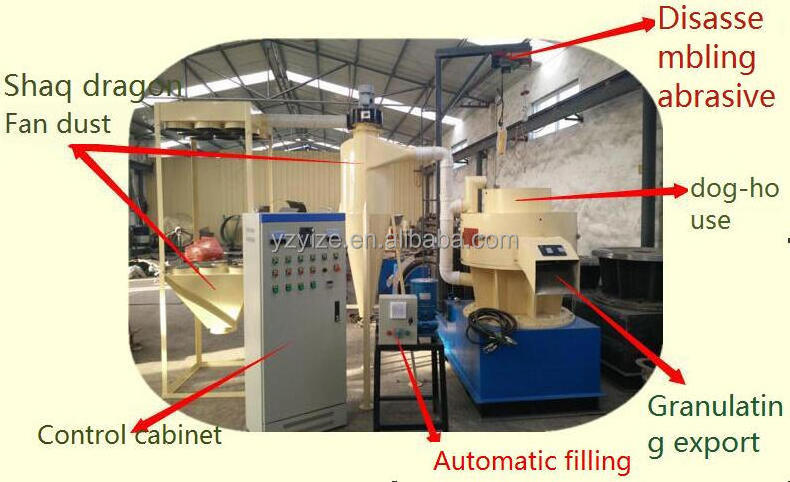

Main process:

Wood chipper--hammer mill--biomass dryer--biomass pellet machine--pellet cooler--pellet packing machine

2. adopting coldpressing molding technology, polishing process. Beautiful appearance, compact structure.

3. using special high quality materials and advanced even shaft driving device, the key components are high quality alloy steel with wear-resisting material, using German vacuum heat treatment furnace, will span the working life to five to seven times.

Main process:

Wood chipper--hammer mill--biomass dryer--biomass pellet machine--pellet cooler--pellet packing machine

Specification

|

Model

|

Power (KW)

|

Capacity

(kg/h)

|

Dimensions

(mm)

|

Weight

(KG)

|

Remarks

|

|

YZ 450

|

55KW

|

800-1200kg

|

1400*750*1550mm

|

2800KG

|

Including fan, electric control,

Particle size: 6-12 MM |

|

YZ 550

|

90KW

|

1500-2000kg

|

1900*950*1800mm

|

4500KG

|

|

|

YZ 700

|

132KW

|

2000-3000kg

|

2500*1350*2100mm

|

7000KG

|

|

|

YZ 800

|

160KW

|

3000-4000kg

|

2650*1450*2100mm

|

8500KG

|

|

Detailed Images

Smaller model Flat pellet making machine

The use of pressure wheel, and both ends of the die disc, the outer ring line speed is consistent, there is no dislocation

friction between the wheel and the die, reduce the resistance, reduce the loss of kinetic energy, prolong the life of the die,

reduce the production cost.

2. Uniform distribution of pressure wheel, smooth operation, while increasing the pressure area, improve production efficiency.

3. Adopt screw center pressure regulating structure, mold clearance as big as small, suitable for different materials, to ensure

the effect of pressing.

4. The model with φ 4-φ 20mm a variety of aperture mold, suitable for different materials granulation, to achieve the best

benefit.

friction between the wheel and the die, reduce the resistance, reduce the loss of kinetic energy, prolong the life of the die,

reduce the production cost.

2. Uniform distribution of pressure wheel, smooth operation, while increasing the pressure area, improve production efficiency.

3. Adopt screw center pressure regulating structure, mold clearance as big as small, suitable for different materials, to ensure

the effect of pressing.

4. The model with φ 4-φ 20mm a variety of aperture mold, suitable for different materials granulation, to achieve the best

benefit.

Related Products

Transanction & Feedback

Customer Feedback

Packing & Delivery

Our Service

Workshop & Company & Customer

FAQ & Contact

Contracter of Diesel Engine Grass Chopper Poultry Cow Chicken Animal Feed Milling Machine Complete Pellet Feeds Progressing Feeding Making Machine

Hot Searches