- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QSFullMetal

-

Model Number:

-

Customized

-

Application:

-

Lid Stock, Industrial Device, Storage

-

Width:

-

500-2200mm

-

Product Name:

-

Aluminum Coil

-

Standard:

-

ASTM AISI JIS DIN GB

-

Material:

-

1100/1050/2024/3003/5052/5083/5086/6061/6082/7021/7075

-

Surface:

-

Coated

-

Advantage:

-

High Corrosion Resistance

-

Coil Weight:

-

3-8 Tons

-

Sample:

-

Sample Freely

-

MOQ:

-

25 Tons

-

Usage:

-

Construction Industry Decoration

-

Price term:

-

CIF CFR FOB EX-WORK

Quick Details

-

Grade:

-

1000 Series

-

Tolerance:

-

±1%

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

QSFullMetal

-

Model Number:

-

Customized

-

Application:

-

Lid Stock, Industrial Device, Storage

-

Width:

-

500-2200mm

-

Product Name:

-

Aluminum Coil

-

Standard:

-

ASTM AISI JIS DIN GB

-

Material:

-

1100/1050/2024/3003/5052/5083/5086/6061/6082/7021/7075

-

Surface:

-

Coated

-

Advantage:

-

High Corrosion Resistance

-

Coil Weight:

-

3-8 Tons

-

Sample:

-

Sample Freely

-

MOQ:

-

25 Tons

-

Usage:

-

Construction Industry Decoration

-

Price term:

-

CIF CFR FOB EX-WORK

Product Overview

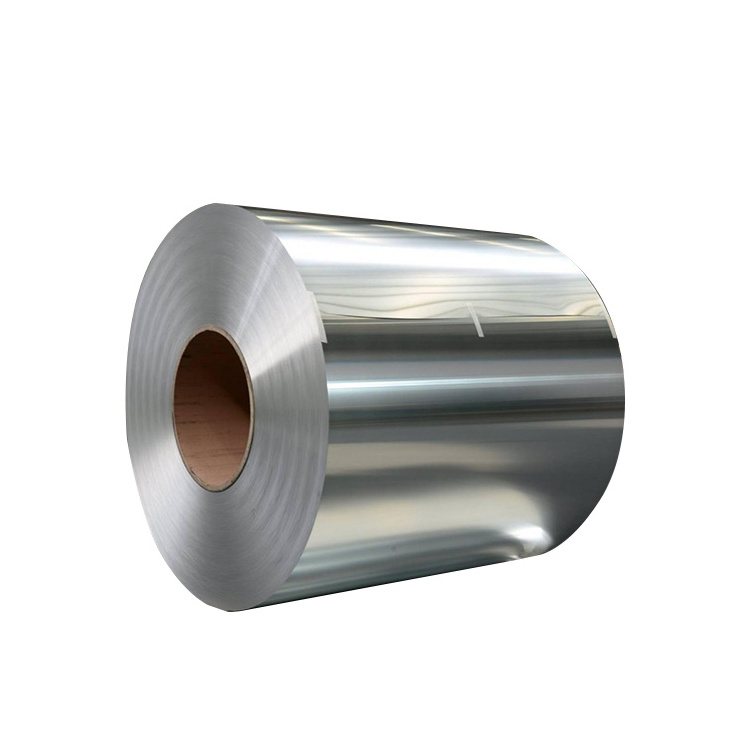

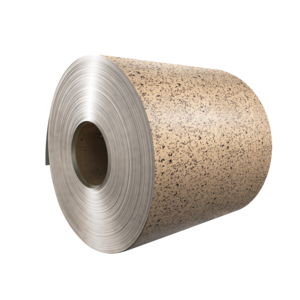

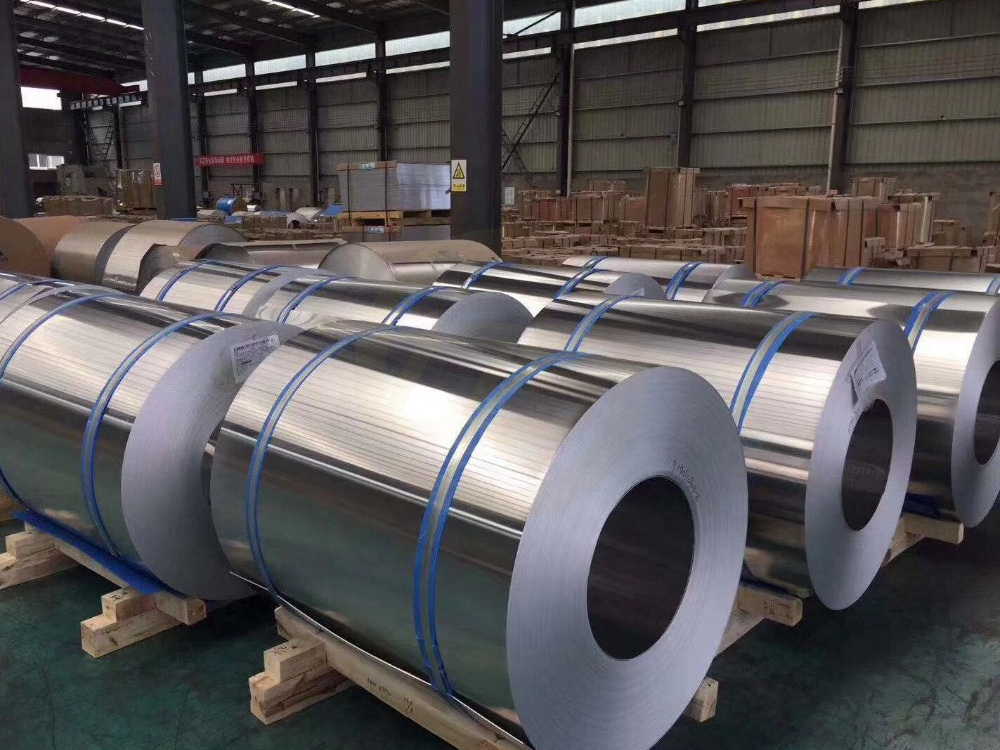

Aluminum Coil

1050 Aluminum Coil Is An Aluminum-Based Alloy In The “Commercially Pure” Wrought Family (1000 Or 1xxx Series). It Has The Characteristics of High Plasticity, Corrosion Resistance, Electrical Conductivity, And Thermal Conductivity. Since 1050 Aluminum Alloy Has A Higher Thermal Conductivity Than Other Alloys. It Has Low Mechanical Strength Compared To More Significantly Alloyed Metals. It Can Be Strengthened By Cold Working, But Not By Heat Treatment. The Production Process Is Relatively Simple And The Price Is Relatively Cheap. It Is The Most Commonly Used Series In The Conventional Industry.

Polished Aluminum Coil refers to the aluminum coils that make the surface of the coils present by the surface of the coils through various methods such as rolling and polishing.

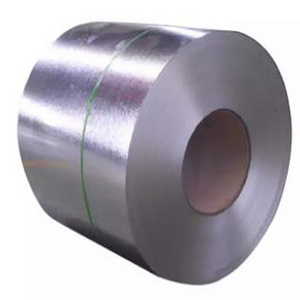

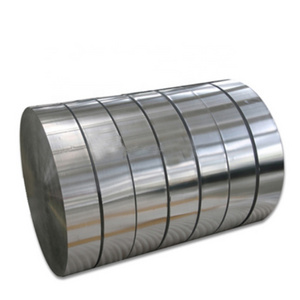

PRODUCT SPECIFICATIONS

|

Product Name

|

Aluminum Coil

|

|

Standard

|

AISI, ASTM, BS, DIN, EN, GB, JIS

|

|

Material

|

1050, 1060, 1100, 1145, 3003, 5082, 6063

|

|

Thickness

|

0.12mm-30mm

|

|

Width

|

600mm-1500mm

|

|

Tolerance

|

+/-0.02mm

|

|

Surface treatment

|

coated

|

|

Coil ID

|

508mm/610mm

|

|

Coil Weight

|

3-8 tons

|

|

Technique

|

Hot rolled, cold rolled

|

|

Package

|

Standard seaworthy export packing:

3 layers of packing, inside is kraft paper, water plastic film is in the middle and outside

GI steel sheet to be covered by steel strips with lock, with inner coil sleeve |

|

Certification

|

ISO 9001-2008, SGS, CE, BV

|

|

MOQ

|

25 Tons

|

|

Delivery

|

15-20 days

|

|

Monthly Output

|

30000 Tons

|

|

Description

|

Advantages of aluminum coils:

Scratch resistance, high surface hardness; Environmental protection, non -toxic, fire prevention; Anti -interference, shielding electromagnetic waves, and excellent heat dissipation performance; Anti -static is not vacuum and is easy to clean, strong fingerprint resistance; Greatly reduce the process of surface treatment; Low proportion, only one -third of stainless steel weighs and is easy to process; The surface oxidation layer will never fall off, and the color is uniform. |

|

Payment

|

T/T, LC, Western Union, Paypal

|

|

Remarks

|

Insurance is all risks and accept the third party test

|

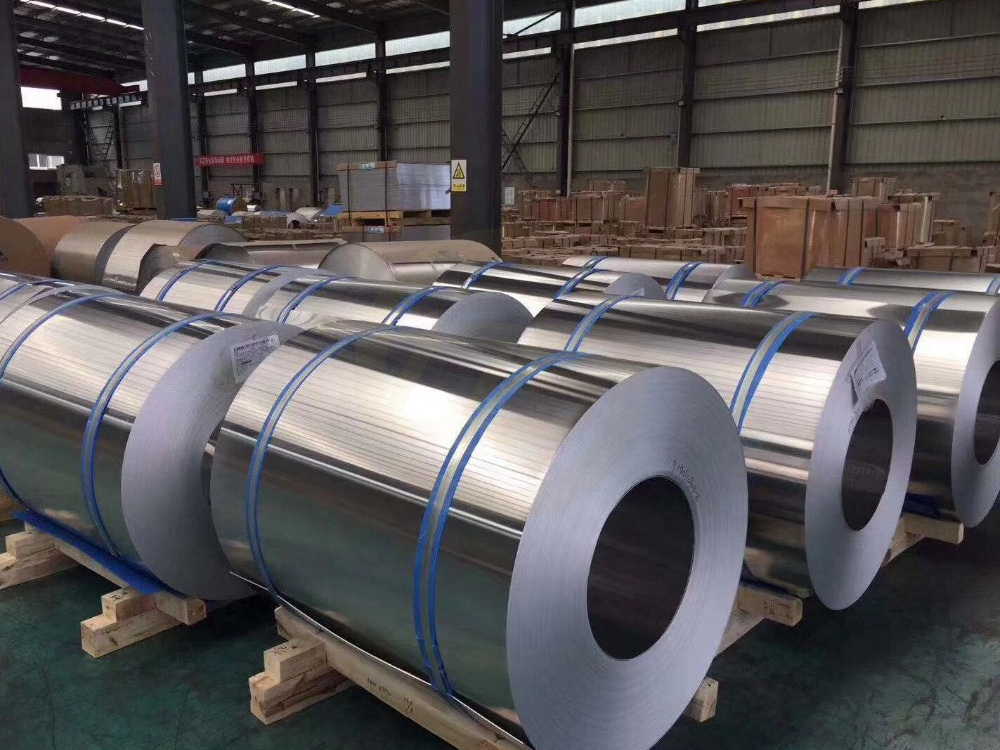

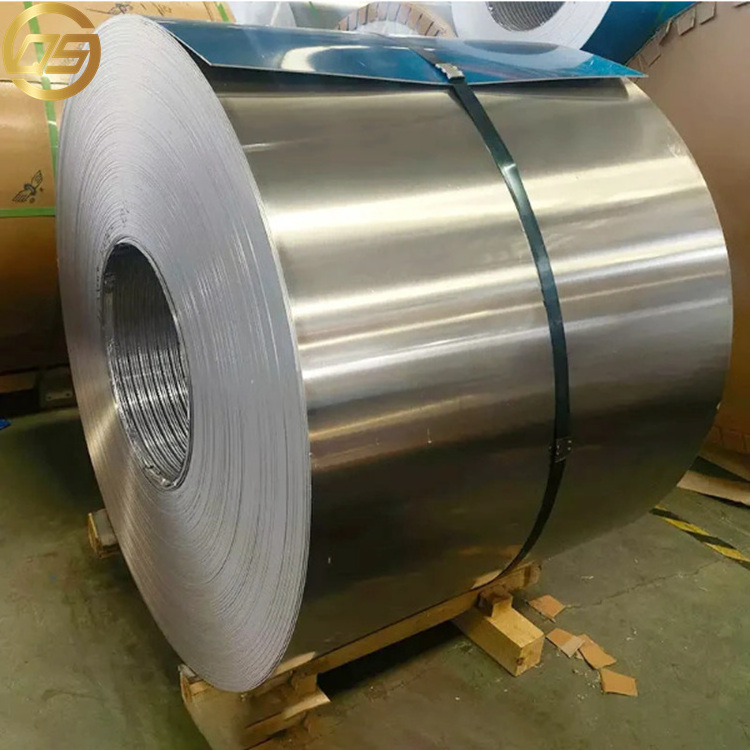

Details Images

Applications

Product packaging

PERFECT PACKING:

Perfect seaworthy package, or as per customer's request.

EXCELLENT TRANSPORT:

Delivery these goods with excellent transporation in 15-35 days after payment.

Perfect seaworthy package, or as per customer's request.

EXCELLENT TRANSPORT:

Delivery these goods with excellent transporation in 15-35 days after payment.

Our Advantages

1. Competitive price with raw material

2. Large production line

3. Excellent quality and abundant stock with fast delivery

1100 is the softest aluminum available. It shows great ductility, corrosion resistance, and high reflectivity. This grade aluminum coil is commonly used for basic cooking utensils, pots and lids, lamps, lanterns, building materials, traffic signs, and ceilings.

3003 aluminum has some of the best formability and is considered on of the most widely used aluminum alloys. It shares many of the same uses as 1100 aluminum, but shows better strength, for example. It can be purposed for more advanced cookware and non-stick pans.

This 5083 alloy has excellent corrosion resistance and tolerates extreme environments like immersion in seawater and industrial chemicals. It is weldable and, among the non-heat treatable alloys, it demonstrates some of the highest strength. Shipbuilding is a common application for this grade.

This 6061 high-strength, general-purpose aluminum is an ideal aluminum where a combination of good surface finishing, corrosion resistance, and good strength-to-weight ratio are required. There are many common applications for this alloy, ranging from structural frame molding to bridge components, sail boats, and other marine applications.

SALES AND SERVICE NETWORK

FAQ

Q1:What is your terms of payment?

A1:We usually accept T/T in advance, and L/C for large sums. If you prefer other payment terms, please discuss them.

Q2:What is your delivery time?

A2:For products in stock, we can ship them within 7 days after receiving the payment. For customer orders, production time is 15-30 workdays after receiving the payment.

Q3:Can I place an sample order and what is your MOQ if l accept your quality?

A3:Yes, we can send you samples but you may pay the express fees and customized samples will take about 7-15 days, our MOQ is 25 tons.

Q4:How could you guarantee your products?

A4:Mill Test Certification is supplied with shipment, We also accept and support third-party inspection. We also could issue a warranty to the customer to guarantee the quality.

Q5:How can I get the price of the needed product?

A5:lt's the best way if you can send us the material, size, and surface, so we can produce it for you to check the quality. If you still have any confusion, just contact us. we would like to be helpful.

Hot Searches