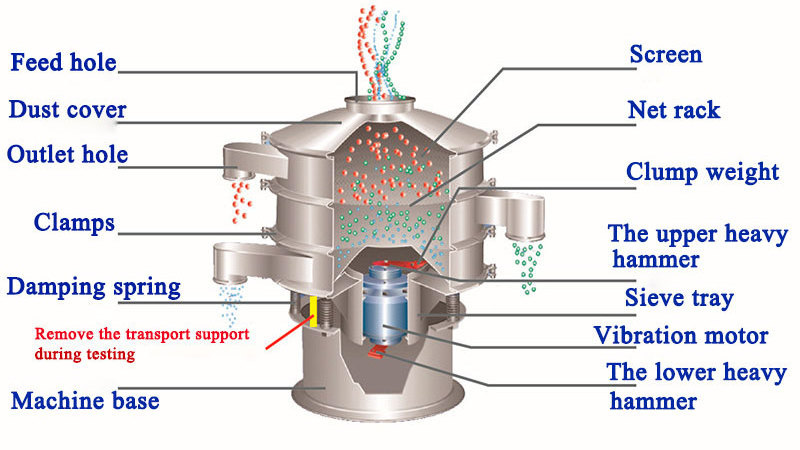

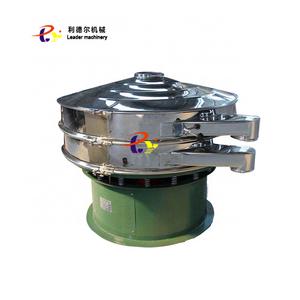

For example, on a 1200mm rotary vibrating screen, the motor consumes 0.45kw, only equivalent to a computer.

With such low energy consumption, an exciting force of 15,000 Newtons can still be exploded stably, ensuring

your output and efficiency.

your output and efficiency.