1. Efficient: Cutting Disc can quickly cut and grind various items with high work efficiency.

2. Durable: The cutting material and structural design of the Cutting Disc make it durable and not easy to wear.

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

T27 T29

-

Product name:

-

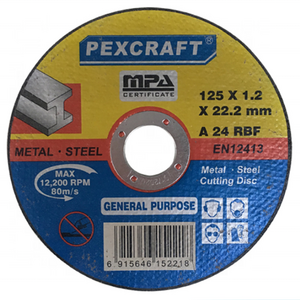

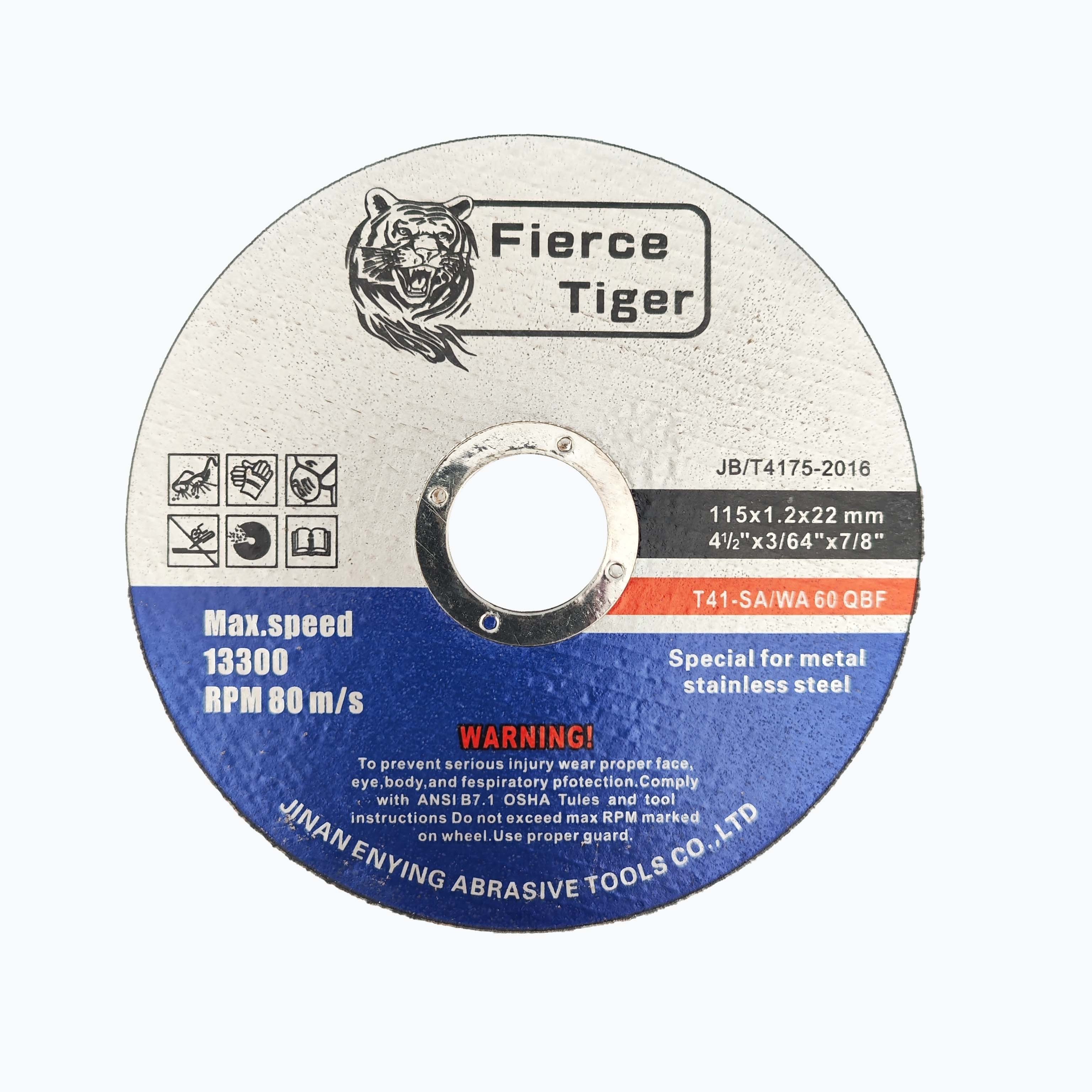

Metal cutting disc cutting wheel 4 inch stainless steel cutting wheel

-

Application:

-

Polishing

-

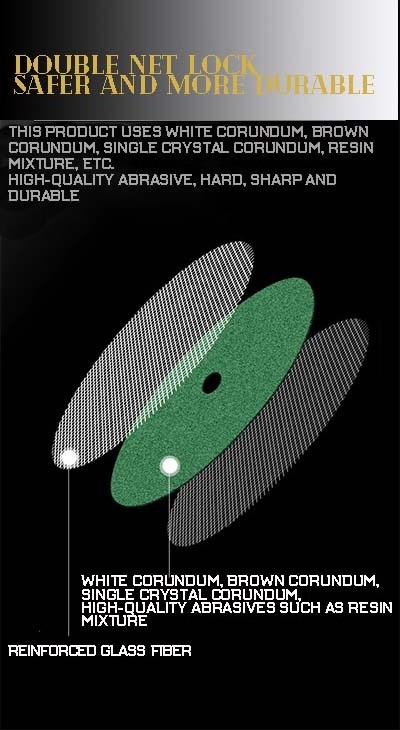

Material:

-

Silicon Carbide CeCeramic Alumina ramic Alumina-Zirconia

-

Size:

-

4"-7"

-

Brand:

-

HD

-

Feature:

-

Sharp Cutting

-

Grit:

-

40#~400#

-

Speed:

-

80m/s 15300M/S

-

Diameter:

-

100mm~180mm

Quick Details

-

Type:

-

Abrasive Disc

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HD

-

Model Number:

-

T27 T29

-

Product name:

-

Metal cutting disc cutting wheel 4 inch stainless steel cutting wheel

-

Application:

-

Polishing

-

Material:

-

Silicon Carbide CeCeramic Alumina ramic Alumina-Zirconia

-

Size:

-

4"-7"

-

Brand:

-

HD

-

Feature:

-

Sharp Cutting

-

Grit:

-

40#~400#

-

Speed:

-

80m/s 15300M/S

-

Diameter:

-

100mm~180mm

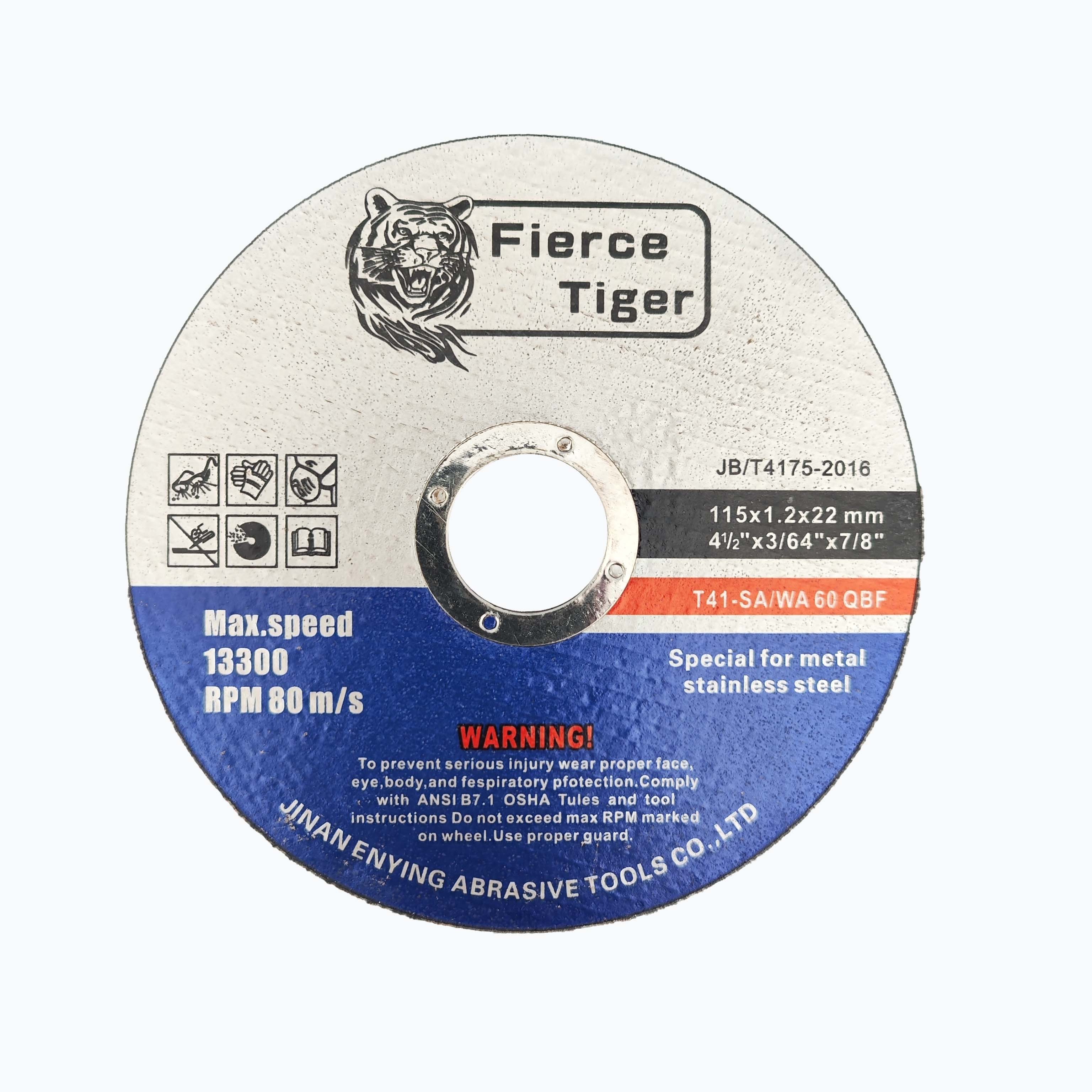

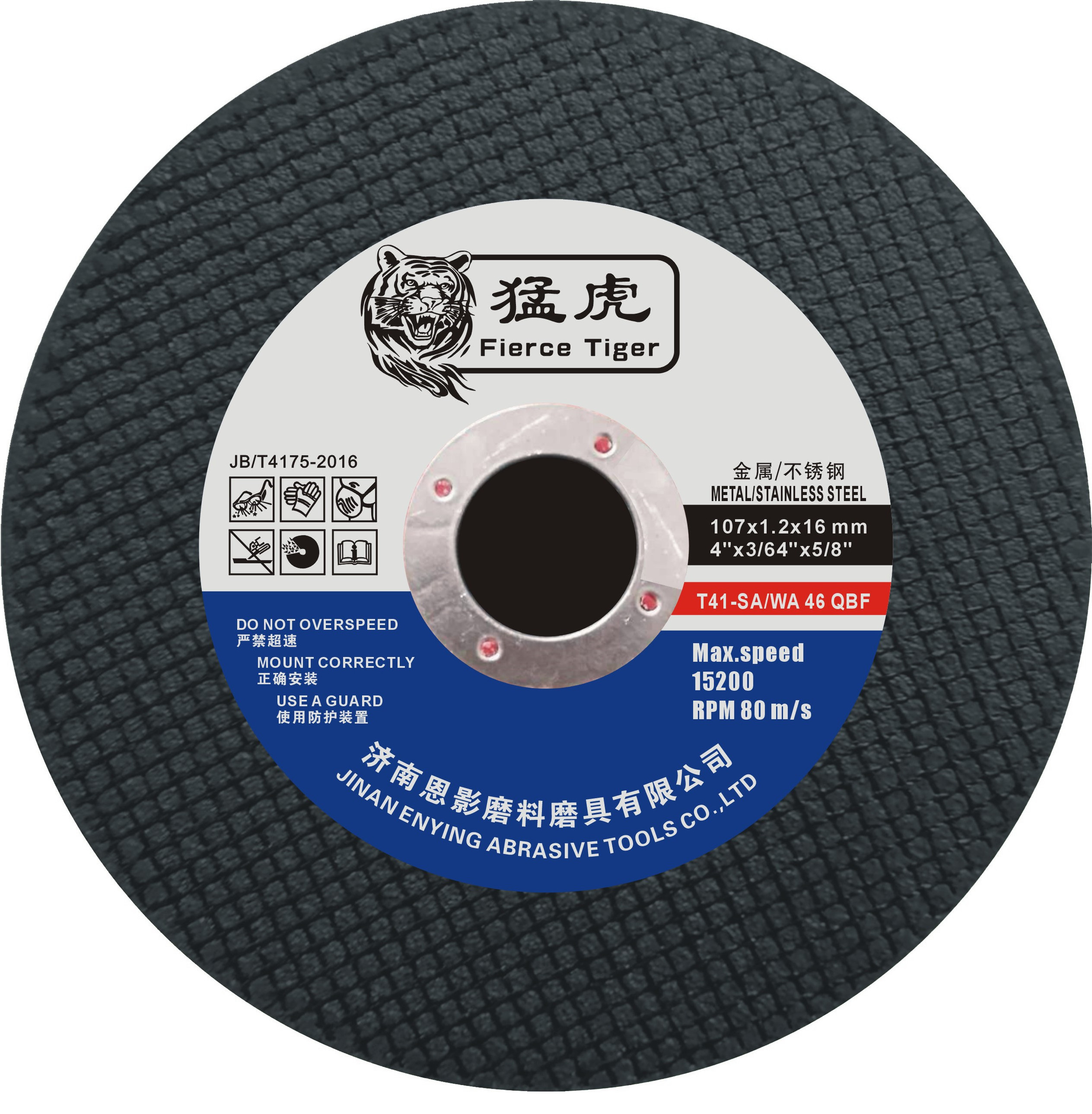

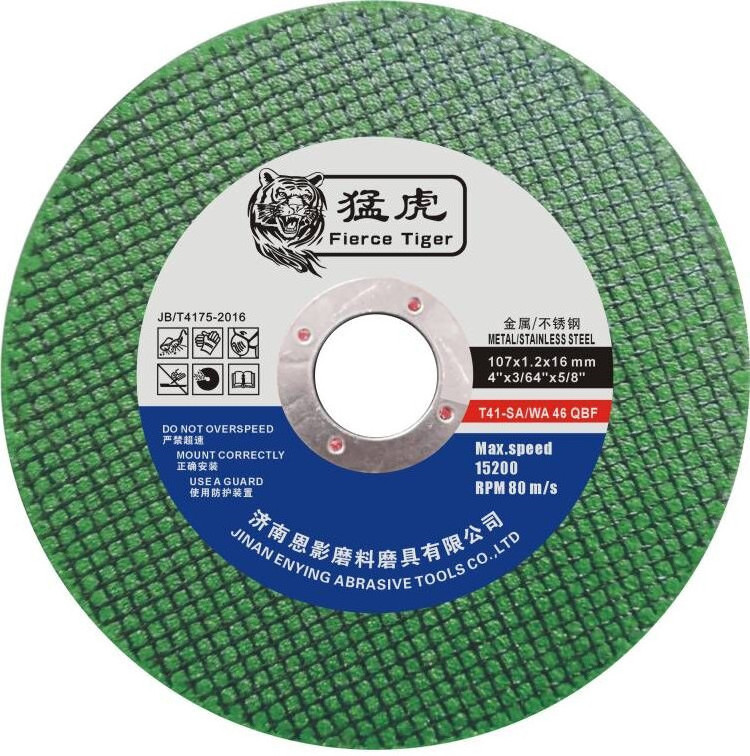

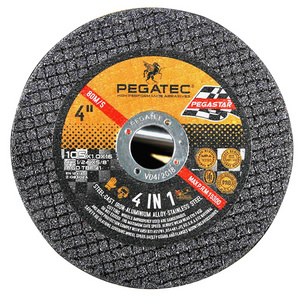

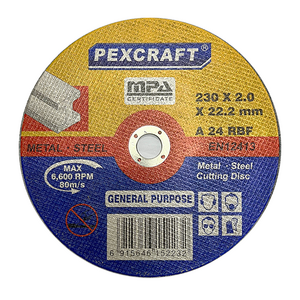

Metal cutting disc cutting wheel 4 inch stainless steel cutting wheel

|

Diameter(MM)

|

Diameter(inch)

|

Pcs/Ctn

|

G.W/N.W(kg)

|

RPM

|

|

105*1.2*16

|

4*3/64*5/8

|

1000

|

27/26

|

15300

|

|

115*1.2*22.2

|

4*3/64/7/8

|

600

|

19/18

|

15300

|

|

125*1.2*22.2

|

5*3/64*7/8

|

500

|

19/18

|

12200

|

|

180*1.6*22.2

|

7*1/21*7/8

|

200

|

12/11

|

8600

|

|

230x2.0x22.23

|

9"×1/12"×7/8"

|

100

|

19/18

|

6600

|

3. Multifunctional: Cutting Disc is suitable for cutting and grinding various materials, such as metal, ceramics, glass, etc.

4.Safety: Cutting Disc needs to pay attention to safety when using it, but it also has a protective design, which can reduce injuries during work.

.

1. Metal cutting: In the field of metal processing, Cutting disc is one of the commonly used cutting tools. It can cut various metal materials quickly and accurately, and it can also easily complete the cutting of parts with complex shapes.

2. Building material cutting: In the field of construction, cutting disc is an important tool for cutting concrete, stone, ceramic tile and other materials. It can cut materials at a high speed on the construction site to improve construction efficiency, and can also be used in a series of building decoration work such as floor and wall paving.

3. Mechanical manufacturing: In the field of mechanical manufacturing, Cutting discs are widely used, such as cutting, polishing and grinding of auto parts. It can not only improve product quality and production efficiency, but also ensure that as little waste as possible is processed.

Safe use

1. Choose the right Cutting Disc: Different cutting and grinding jobs require different Cutting Discs, so choose the right tool.

2. Correct operation: When using the Cutting Disc, follow the operating procedures, pay attention to work safety, and prevent accidental injuries.

3. Maintain tools: keep the Cutting Disc clean and maintained, and replace worn tools in time to ensure work efficiency and tool life.

Jinan Enying Machinery Manufacturing Co.,Ltd. After years of development, we are now a manufacturing enterprise group that produces and processes. At present the company's products have increased from flanges, abrasive materials. we mainly focus on manufacture and export : flap disc ,sanding disc ,cutting wheel ,flange , Our products are widely recognized and trusted by clients. Relying on "Competitive Price,Superior Quality and Good Service", we have lots of long-cooperated customers and we pledge to do our best to serve every customer.

Certifications

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly,convenient and efficient packaging services will be provided.

FAQ

Q: Do you accept OEM Brand?

A: Yes,OEM Brand is accepted.We can also design label for you for free.

Q:Are samples available for quality test?

A: Yes,The clents need to pay the sample cost and freight charge , but the sample cost will be return back to client after order confirmed in future.

A: Yes,The clents need to pay the sample cost and freight charge , but the sample cost will be return back to client after order confirmed in future.

Q: Do you have any certificate?

A: Yes, we have MPA,ISO certificates

A: Yes, we have MPA,ISO certificates

Q:How could you ensure the quality?

A:Only high quality and stable batch products can ensure user's safety and consistent effect.To ensure this, all our products will pass the semi-product testing, finished- product testing and inspection before delivering.Quality passes only after 3 times testing.

A:Only high quality and stable batch products can ensure user's safety and consistent effect.To ensure this, all our products will pass the semi-product testing, finished- product testing and inspection before delivering.Quality passes only after 3 times testing.

Contact us

Whatsapp/

wechat

:+0086-15628888834

liyue@zqhongdun.com

Hot Searches