- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1.8*1.9*1.21m

-

Weight:

-

5030kg

-

Warranty:

-

One Year

-

Product name:

-

tractor wood chipper

-

Inlet size(L*H):

-

230*500mm

-

Blade numbers:

-

2 pieces

-

Knife roller speed:

-

590r/min

-

Raw material max diameter:

-

230mm

-

wood chips size:

-

30mm

-

Capacity:

-

7-8t/h

-

Main motor power:

-

55kw

-

Oil pump motor power:

-

1.5*1kw

-

Feed roller motor power:

-

3-4kw

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

Quick Details

-

Use:

-

Wood Chipping

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingyang

-

Dimension(L*W*H):

-

1.8*1.9*1.21m

-

Weight:

-

5030kg

-

Warranty:

-

One Year

-

Product name:

-

tractor wood chipper

-

Inlet size(L*H):

-

230*500mm

-

Blade numbers:

-

2 pieces

-

Knife roller speed:

-

590r/min

-

Raw material max diameter:

-

230mm

-

wood chips size:

-

30mm

-

Capacity:

-

7-8t/h

-

Main motor power:

-

55kw

-

Oil pump motor power:

-

1.5*1kw

-

Feed roller motor power:

-

3-4kw

-

Local Service Location:

-

None

-

Certification:

-

CE ISO

CE approved tractor wood chipper/firewood chips making machine/drum bamboo chipper

After making the chips, to use our crusher machine to get sawdust, then use the dryer machine to dry the sawdust if the sawdust moisture is high; then use

1) our sawdust briquette machine to make the briquette and if you want to get charcoal briquette, then you can use the carbonization furnace to get charcoal briquette. https://www.alibaba.com/product-detail/Smokeless-and-CE-approved-wood-charcoal_60188091042.html?spm=a271v.8028081.0.0.Fml6qH

2) our sawdust pellet machine to make the pellet and if you want to pack the pellet, then you can use the pellet cooler machine to cool the pellet and then use the packing machine to pack them. https://www.alibaba.com/product-detail/1-5-ton-per-hour-Hot_60180544741.html?spm=a271v.8028081.0.0.Fml6qH

1. tractor wood chipper main data:

| Model | MY-BX215 | MY-BX216 | MY-BX218 | MY-BX2113 |

| lnlet size(H*W)(mm) | 160*400 | 230*500 | 300*680 | 450*700 |

| Blades number (pcs) | 2 | 2 | 2 | 2 |

| Knife roller speed(turn) | 592 | 590 | 650 | 500 |

| Max. Diameter (mm) | 160 | 230 | 300 | 450 |

| Woodchips size (mm) | 30 | 30 | 30 | 38 |

| Capacity (T) | 3.4 | 7-8 | 12-15 | 15-30 |

| Main motor power (kw) | 45 | 55 | 110 | 200-250 |

| Feed roller motor power(kw) | 2.2-3 | 3-4 | 4-5 | 7.5*2 |

| Oil pump motor power (kw) | 1.5*1 | 1.5*1 | 1.5*1 | 3*1 |

| Weight (kg) | 2990 | 5030 | 7000 | 11840 |

| Outline Dimension (mm) | 1470x1550x970 | 1800x1900x1210 | 2200x2150x1500 | 3670x2517x2050 |

| Converyor motor power (kw) | 3 | 3 | 3 | 3 |

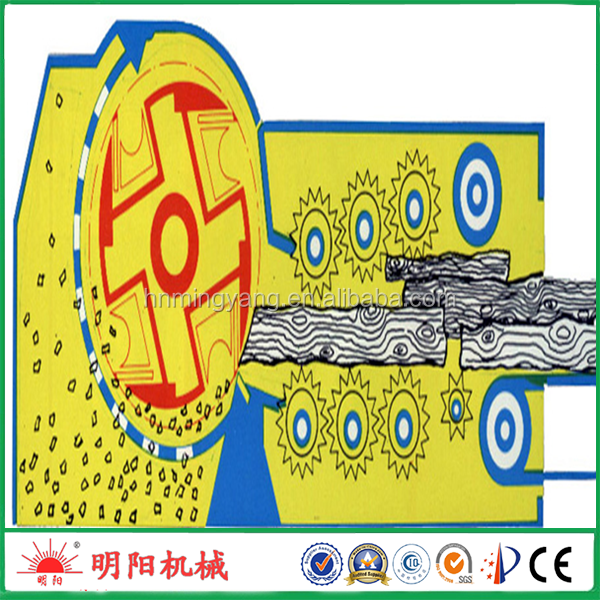

2. tractor wood chipper introduction:

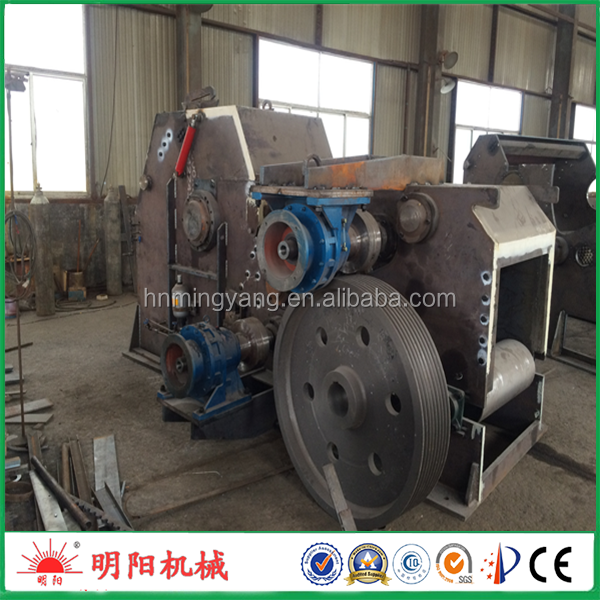

tractor wood chipper features a large, motor-powered drum located at the center of the machine. It is a dedicated device producing quality wood chips for energy generation and wood pulp industry. That’s why it is popular in places where wood chips used as the starting material for further production like wood pellet plant, particleboard mill, fiberboard factory, biomass power plant, etc. The chipping materials are of great variety such as wood, stalk or straw, etc. Our wood drum chipper is extremely robust and scientifically designed which can transfer wood materials into uniform and high quality chips.

3. What raw material can be used for the tractor wood chipper:

Our tractor wood chipper is versatile and suitable to chip a myriad of raw materials for wood pelletizing.

--for wood materials, it can chip undersized branches, slabs, plump wood, panels manufacturing, leftovers of furniture factories, plant fibers and so on;

--for non-wood materials, drum chipper is fit for sugarcane stalk, bulrush and bamboo.

4. Final chips from the wood chipper:

5. The working principles of the tractor wood chipper:

the main parts of the tractor wood chipper include: machine rack, the blades rollers, double feeding rollers, the transmission belt and the hydraulic buffer system. The blades roller in the crushing room is connected with the electric motor by the transmission belt. The raw materials is clamped and transmitted to the crushing space by the feeding system, then crushed by the fast rotating blades on the roller frequently. The larger wood chips will be processed for several time before discharged from holes on the screen. At last, the wood chips with flat incision, even length, uniform thickness are discharged.