- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Friend

-

Voltage:

-

380V or customize

-

Dimension(L*W*H):

-

8m*1m*2m

-

Power (kW):

-

11

-

Weight:

-

1400 KG

-

After-sales Service Provided:

-

Overseas service center available

-

Name:

-

PTFE Pipe Making Machine

-

Raw material:

-

PTFE granules

-

Usage:

-

Wide Usage

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

Pipe

-

Color:

-

Grey

-

Product:

-

PFA PTFE Pipe

-

Type:

-

Pipe Machine

Quick Details

-

Screw Design:

-

Single-screw

-

Screw L/D Ratio:

-

28:1

-

Screw Speed (rpm):

-

110 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Friend

-

Voltage:

-

380V or customize

-

Dimension(L*W*H):

-

8m*1m*2m

-

Power (kW):

-

11

-

Weight:

-

1400 KG

-

After-sales Service Provided:

-

Overseas service center available

-

Name:

-

PTFE Pipe Making Machine

-

Raw material:

-

PTFE granules

-

Usage:

-

Wide Usage

-

Processing Type:

-

Exturding Machine

-

Product Type:

-

Pipe

-

Color:

-

Grey

-

Product:

-

PFA PTFE Pipe

-

Type:

-

Pipe Machine

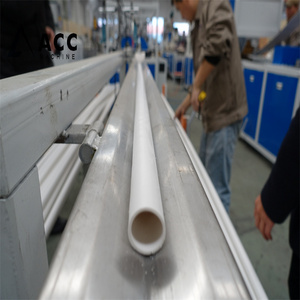

1/2 inch 1/8 inch PTFE PFA Pipe Production Line

Product Description

PTFE tube

Features: PTFE tube is manufactured by ram extruded with PTFE granular resin, PTFE is the most cororsion resistance resistance of all known Plastics. It has the best electrical properties of plastics.PTFE tube produced in PTFE dispersion resin through high temperature sintering, it has excellent performance of high and low temperature resistance, corrosion resistance, wear resistance,electrical properties with no adhesion, its widely used in wear sleeve, corrosion sleeve , insulation sleeve , the transmission of gas and liquid pipe and automotive throttle sleeve,

Paint spray equipment. Apply to national defense, chemical, pharmaceutical. petroleum, electronics, telecommunications, textile,automotive, aerospace and appliance industries.

Use: Insulating cover for conductor, pipe for corrosive fluids.

Main properties

Properties Unit Result

Apparent density g/cm3 2.10 -- 2.20

Tensile strength (min)≥ MPa 18.0

Ultimate elongation (min)≥ % 230

Residual Lubricant Content(max)< % 0.5

Composition

| 1 | Feeding device | 1 set |

| 2 | Extruder | 1 set |

| 3 | Die head | 1 set |

| 4 | Vacuum tank | 1 set |

| 5 | Haul-off | 1 set |

| 6 | Winding machine | 1 set |

| 7 | Accessory list | 1 set |

| 8 | Control cabinet | 1 set |

Main Parameter

Picture

Hot Searches