projects.

- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

7000 KG

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

Customised

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Sand Blaster

-

Function:

-

clean workpiece

-

Application:

-

Rust Removal

-

Product name:

-

Concrete Floor Shot Blasting Machine

-

Color:

-

Customers Requirement

-

Blast chamber:

-

Structural Steel

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

PUHUA

-

Marketing Type:

-

New Product 2023

-

Weight (KG):

-

7000 KG

-

Power:

-

Customizd

-

Dimension(L*W*H):

-

Customised

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

Sand Blaster

-

Function:

-

clean workpiece

-

Application:

-

Rust Removal

-

Product name:

-

Concrete Floor Shot Blasting Machine

-

Color:

-

Customers Requirement

-

Blast chamber:

-

Structural Steel

Products Description

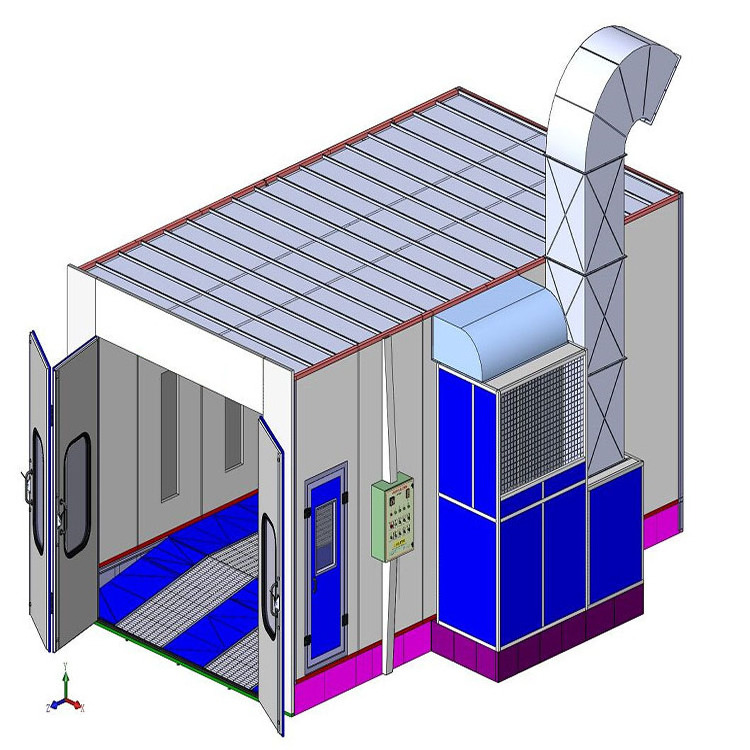

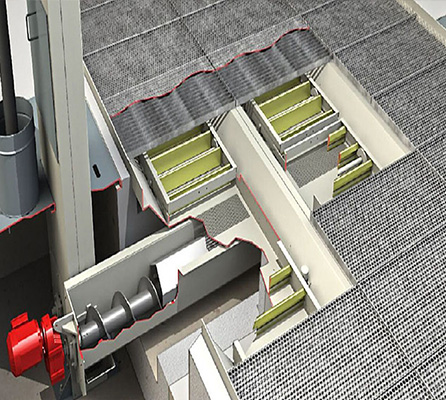

Sand Blasting Room/Sandblasting Booths for sale

Sand blasting room/Spray booth/Painting room also called sand play room, suitable for large work piece surface cleaning, rust removal, increase the work piece and the adhesion between the coating effects, sandblasting room according to the abrasive way of recycling peening room is divided into: mechanical recycling type shot blasting room and artificial recovery type shot blasting room. The artificial recycling sandblasting room due to the economic and practical, simple, convenient, simple materials, greatly reduced the cost of sandblasting room cost, also accepted by many customers, especially small and medium-sized enterprises.

Technical parameter

|

Max. Workpiece size (L*W*H)

|

7*3.5*2.5 m

|

|

Max. Workpiece weight

|

Max. 5 T

|

|

Finish level

|

Can achieve Sa2-2 .5 (GB8923-88)

|

|

Processing speed

|

30-60 m3/min (Operator start different blasting guns quantity)

|

|

Surface roughness

|

40~75 μ (Depend on abrasive size)

|

|

Suggest abrasive

|

Grinding steel shot, Φ0.5~1.5

|

|

Sand blasting room inside

dimension (L*W*H) |

15*8*6 m

|

|

Electric power supply

|

380V, 3P, 50HZ or customized

|

|

Pit requirement

|

Waterproof

|

Detail Image

OEM/ODM

projects.

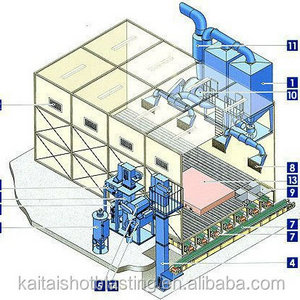

Recycle abrasives from the floor in time without dead ends and clean them

The blasting turbines, maintenance door, abrasive controller and abrasive circulation system are equipped with electric interlock

and self-locking system to ensure the reliable operation of the equipment and the safety of operators.

The dust removal system consists of ducting system and filter cartridge dust collector. The emission standard can be lower 80 g/m3.The fan power is 30 kw, ventilation quantity is 26000 m3/h.

The trolley load-bearing is 10T.total length of rail is 35 m. To prevent the projectile wheel stuck phenomenon, there are polyurethane scraper in front of each wheel to strike off scattered abrasive on the track.

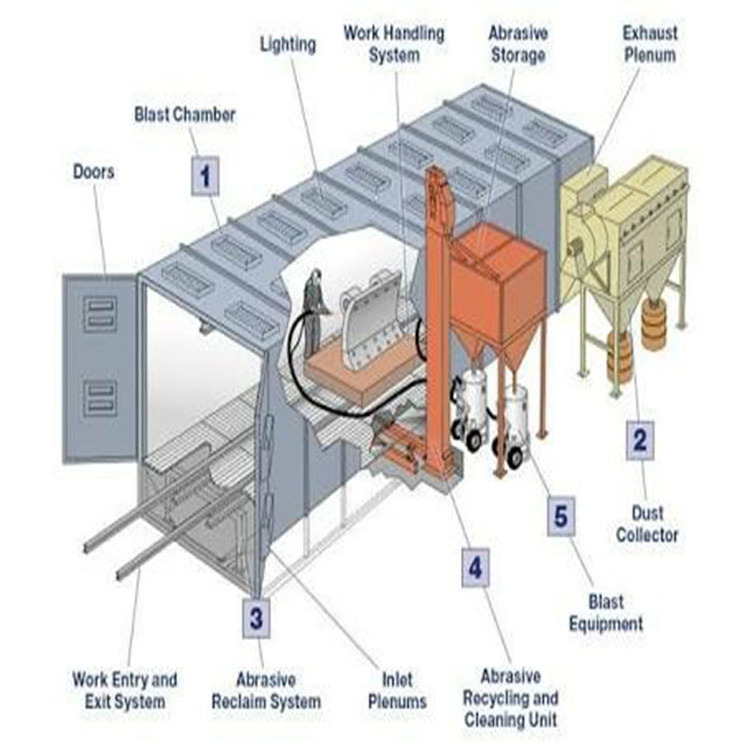

Structural characteristics:

Shot blasting system

The shot blasting system is equipped with 1 set sand blasting pot, 1-2 guns. We fully take into account the operation convenience of the workers, specifically increased the shot blasting chamber operating space, set lighting system and platform, so that workers can operate convenient, effective and comprehensive on piece parts for shot-peening.

This machine equipped with shot peening special protective mask, greatly improving the working environment, and protect the health of operating workers.

Shot distributing system

This machine adopts the patented shot valve produced of our company; it can accumulate a certain time in blasting, through the manual control to provide the shot ball to the blasting device.

Dust-removing system

This machine adopts Cartridge or bag type dust collector, is exhausted air produced during working. The dedusting efficiency is up to 99.6%, powder density is less than 100mg/m3,much stricter than the national standard.

Electric control system

Set shot ball circulatory failure alarm function, if any parts of the system fails, the above components automatically stop running, to prevent the shot ball stuck and burning power device.

Notice:

According to your requirements, the most suitable machines will be designed for your workpieces, please indicate the folloing details.

1. What kind of workpiece will you clean?

2. The workpiece size, length, width, height and weight of maximum workpiece.

3. How many workpieces do you want to clean per day?

Based on this detail information, the detailed technical proposals will be sent to you for reference.

Blasting Sample

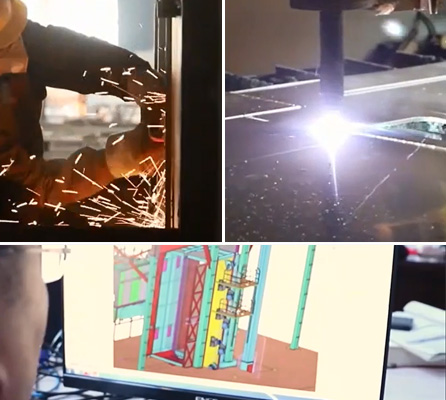

Work shop

Hot Searches