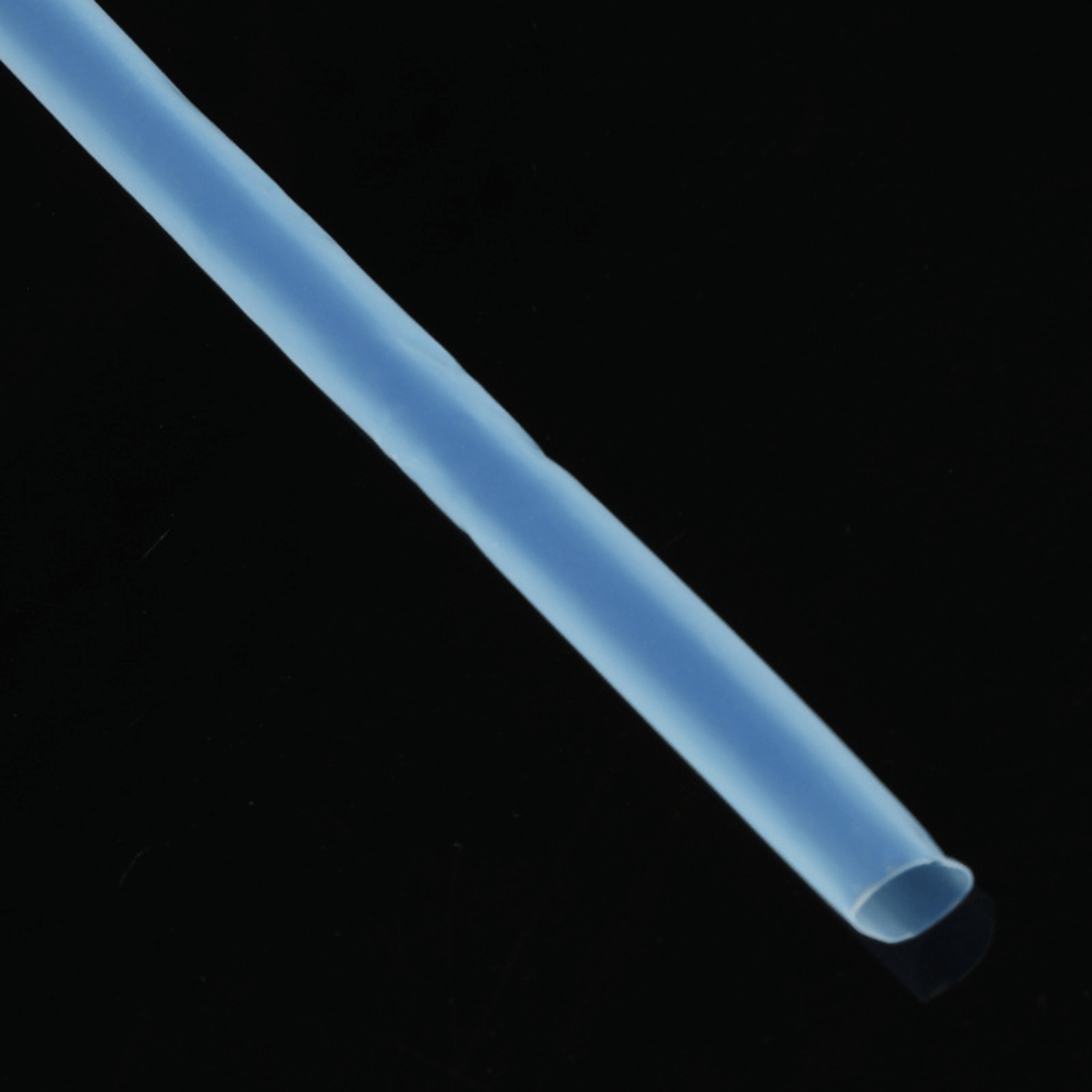

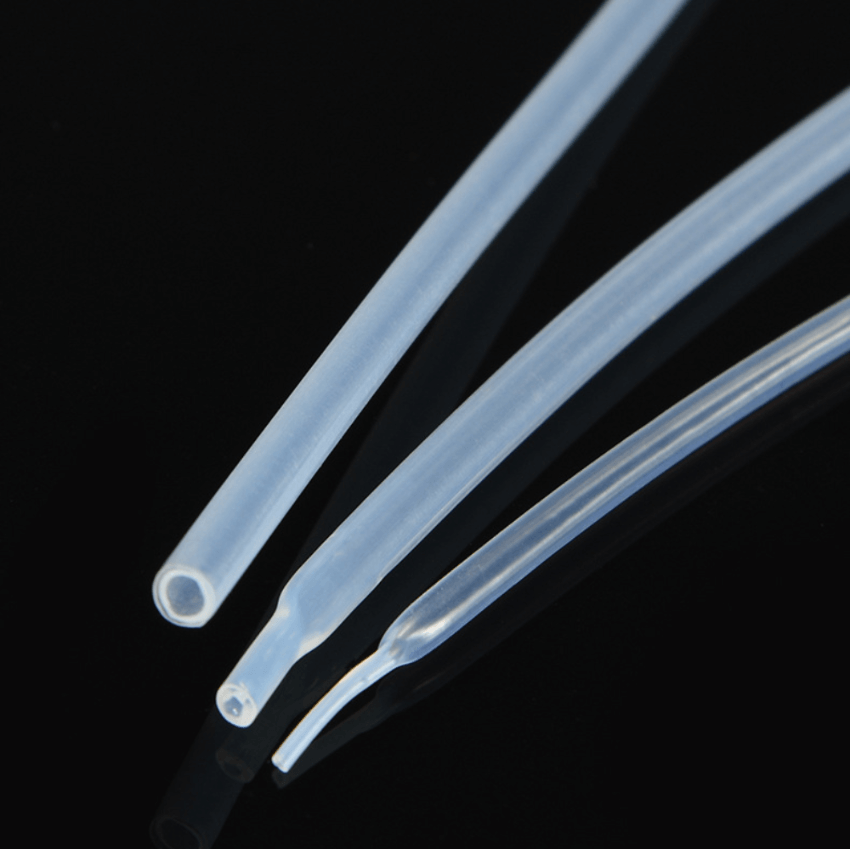

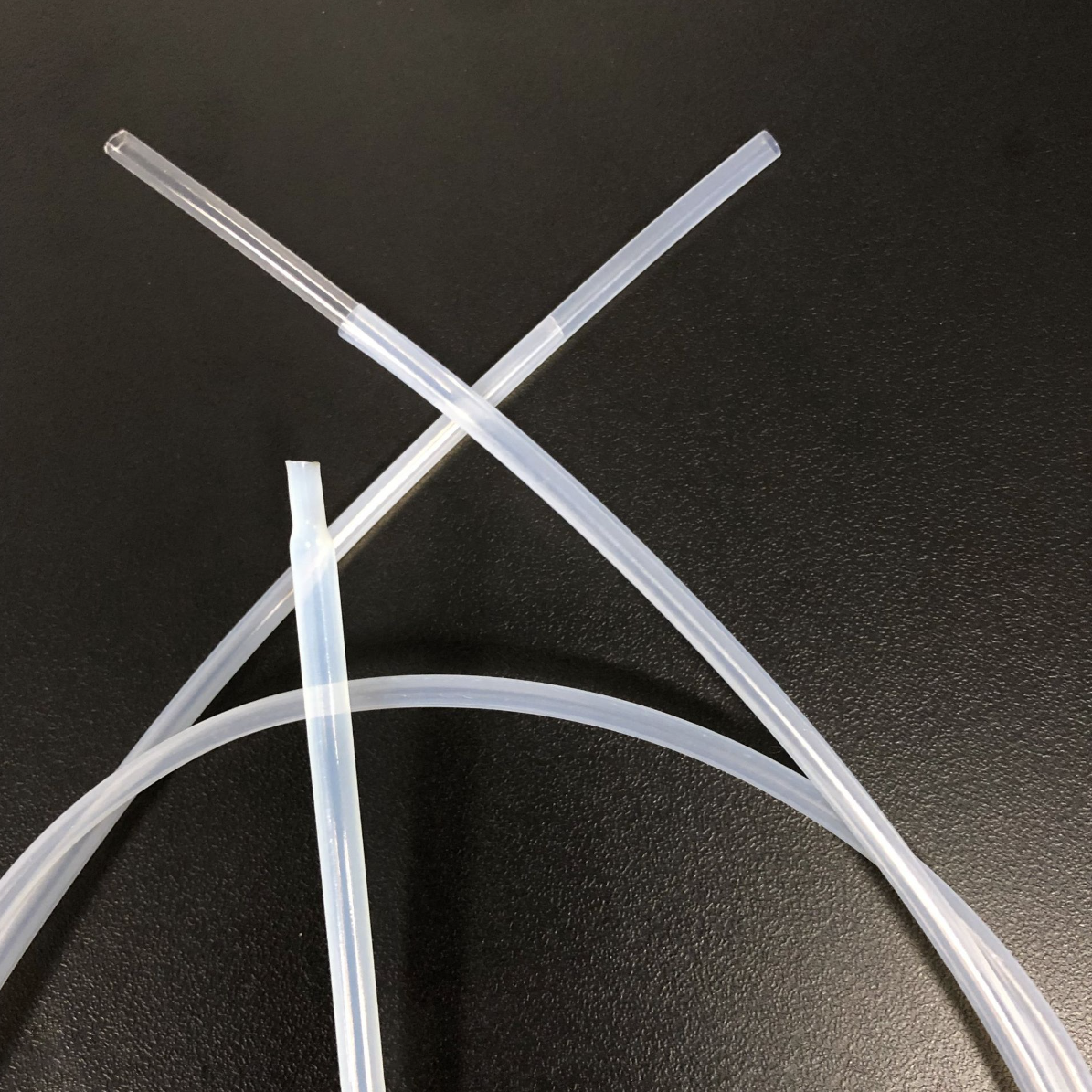

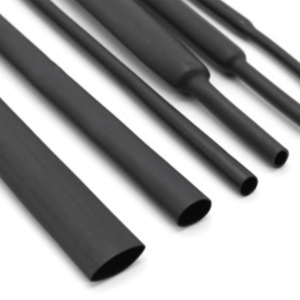

PTFE heat-shrinkable tube is made of imported high-quality polytetrafluoroethylene (commonly known as plastic king) resin and processed by special methods. The product has the advantages of high temperature resistance, high pressure resistance, corrosion resistance, wear resistance, and good mechanical strength. Widely used in various fields such as machinery, electronic chemical industry, communication, etc.

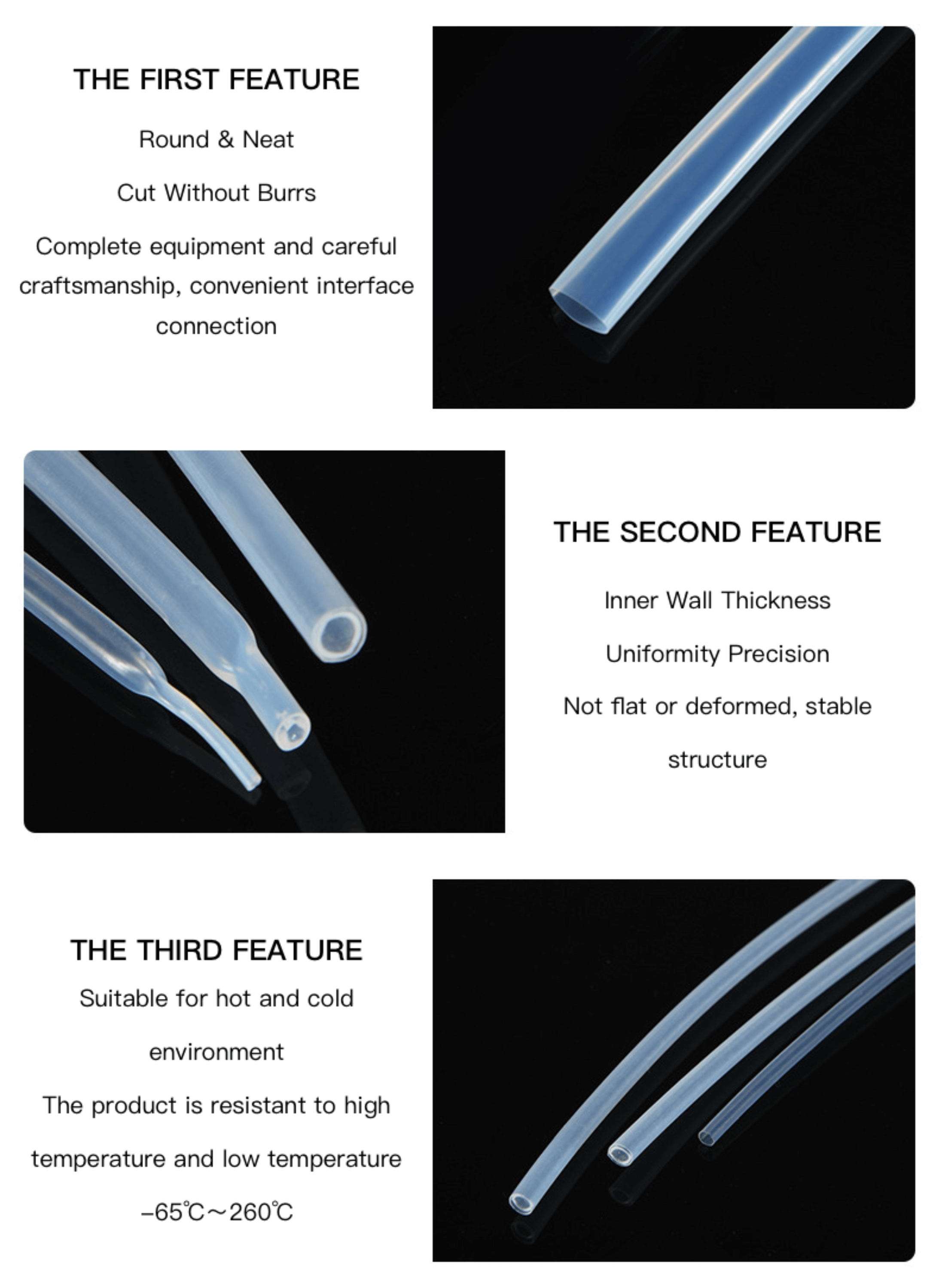

Features

Technical Data