- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Hydraulic Cyliner

-

Seals:

-

Imported Brand

-

Certificate:

-

ISO9001:2008/TS16949

-

Mounting Style:

-

Head Square Flange

-

Port Size:

-

M5x0.8~1"

-

After Warranty Service:

-

Online Support

-

Keyword:

-

Double Acting Telescopic Hydraulic Cylinder

-

Application:

-

Metallurgical Machinery

-

Working Temperature:

-

5-70 Degree

-

Fluid:

-

Filtered Clean Air

Quick Details

-

Weight (KG):

-

50

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

powersen

-

Product name:

-

Hydraulic Cyliner

-

Seals:

-

Imported Brand

-

Certificate:

-

ISO9001:2008/TS16949

-

Mounting Style:

-

Head Square Flange

-

Port Size:

-

M5x0.8~1"

-

After Warranty Service:

-

Online Support

-

Keyword:

-

Double Acting Telescopic Hydraulic Cylinder

-

Application:

-

Metallurgical Machinery

-

Working Temperature:

-

5-70 Degree

-

Fluid:

-

Filtered Clean Air

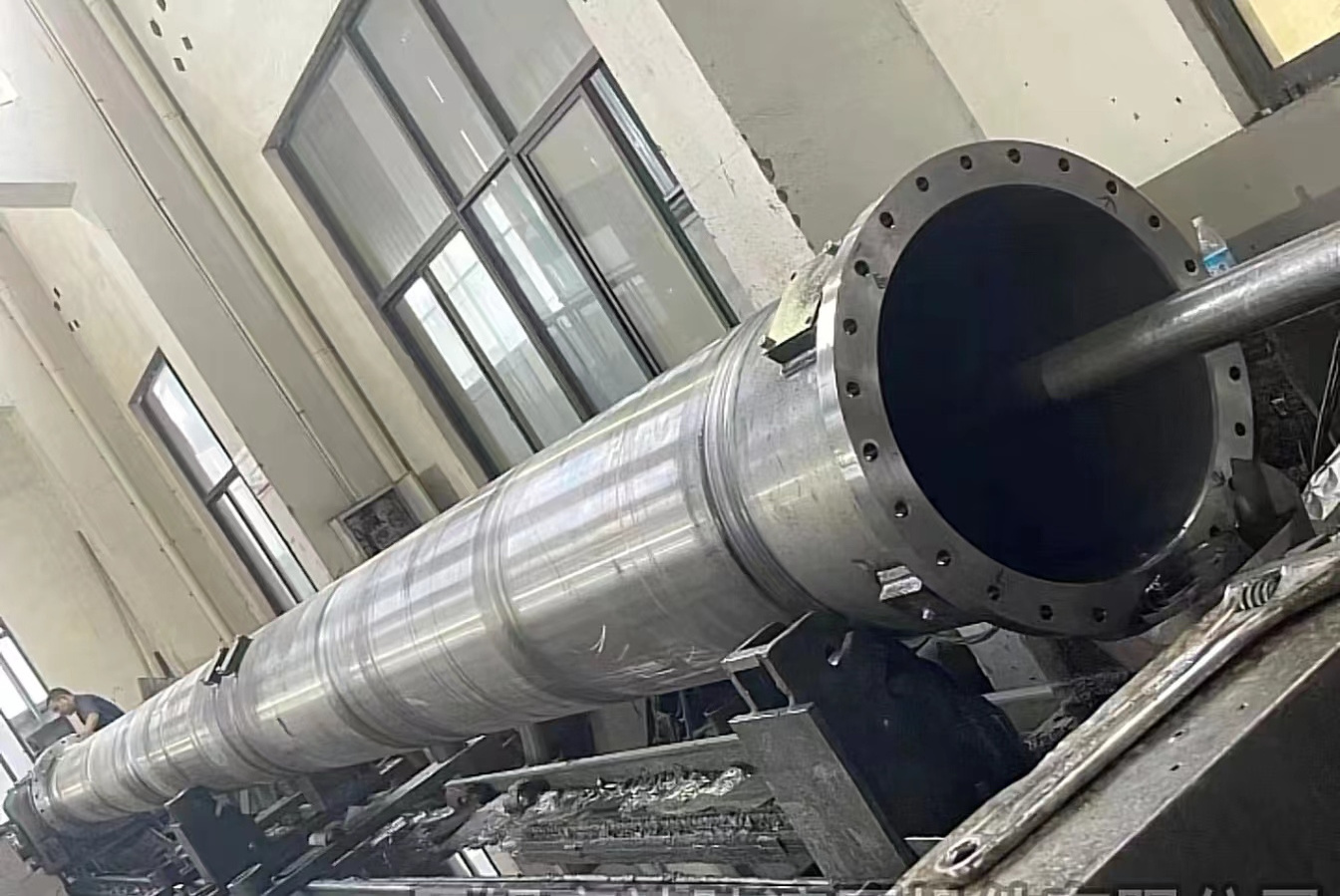

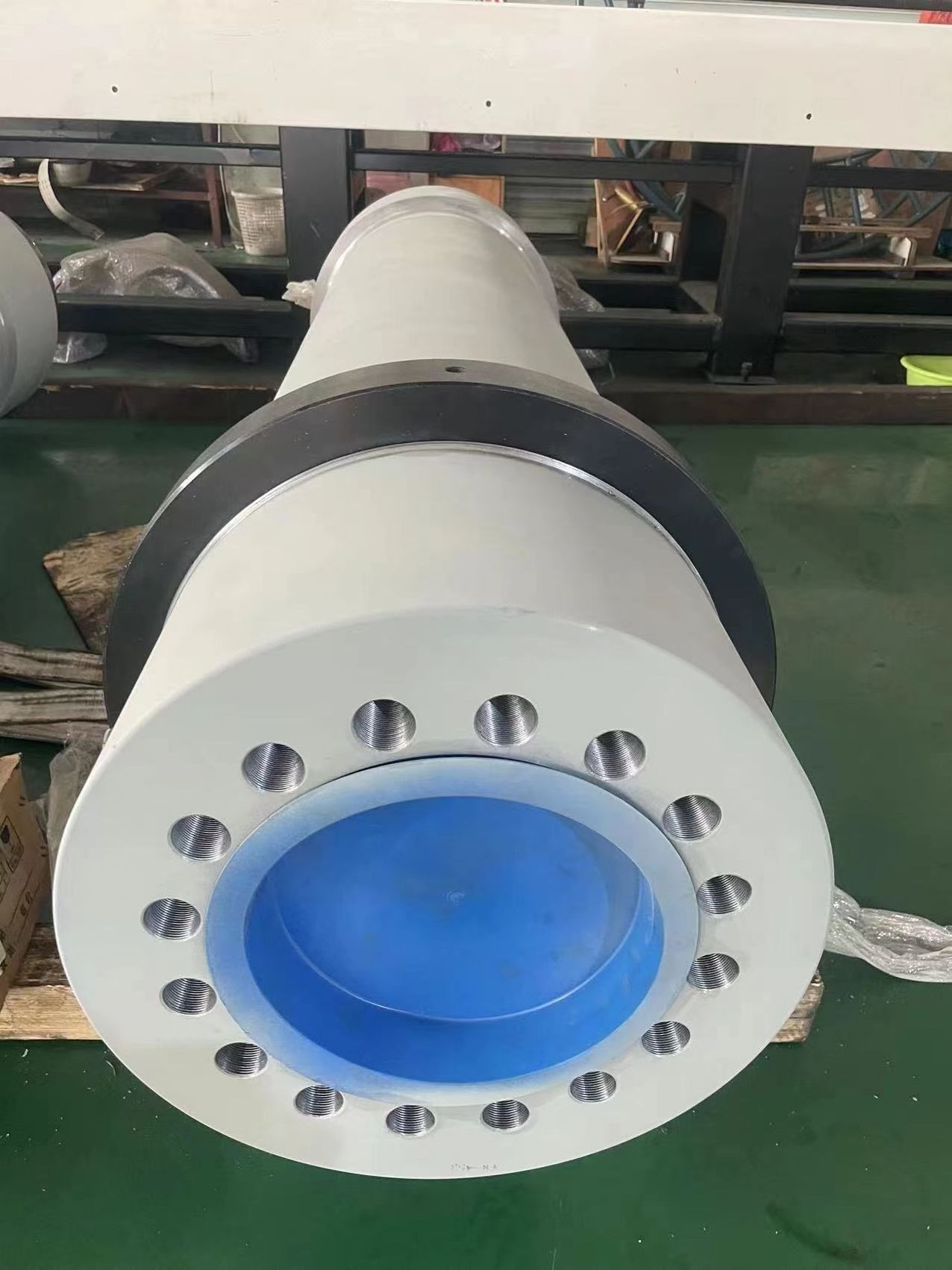

Product Overview

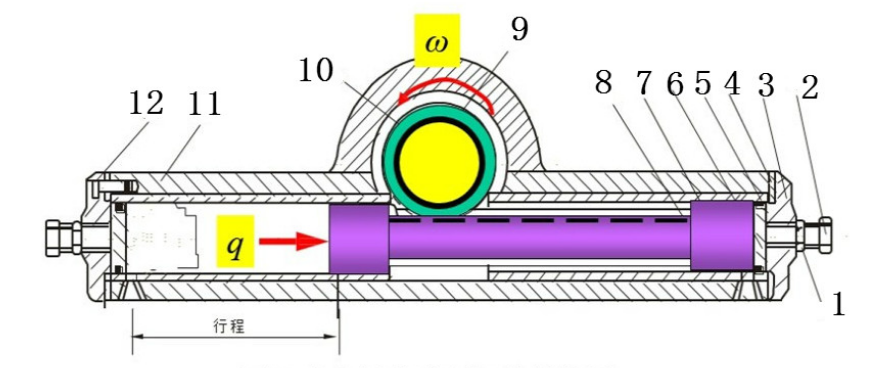

Rack Piston Type Hydraulic Cylinder Structure Drawing

|

1

|

fastening nut

|

5

|

O type sealing ring

|

9

|

Gear

|

|

2

|

adjusting screw

|

6

|

retaining ring

|

10

|

transmission shaft

|

|

3

|

End cup

|

7

|

cylinder liner

|

11

|

Cylinder block

|

|

4

|

washer

|

8

|

Rack piston

|

12

|

screw

|

The hydraulic cylinder has a variety of structural forms, and its classification methods are also various: according to the mode of movement, it can be divided into linear reciprocating movement and rotary swing type; According to the action of liquid pressure can be divided into single acting type, double acting type.

According to the structure, it can be divided into piston type, plunger type, multistage telescopic sleeve type, pinion and rack type, etc. According to the installation form can be divided into rod, earring, foot, hinge shaft and so on; According to the pressure grade can be divided into 16Mpa, 25Mpa, 31.5Mpa and so on.

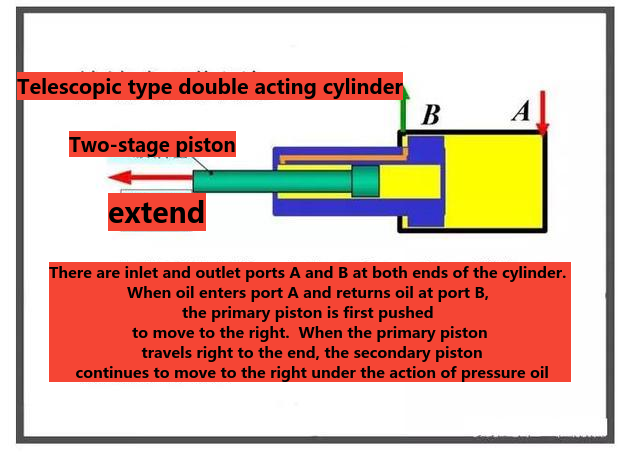

Telescopic Type Double Acting Cylinder

There are inlet and outlet ports A and B at both ends of the cylinder,when oil enters port A and returns oil at port B,the primary piston is frist pushed to moved to the right.when the primary piston travels right to the end,the secondary piston continues to move to the right under the action of pressure oil;

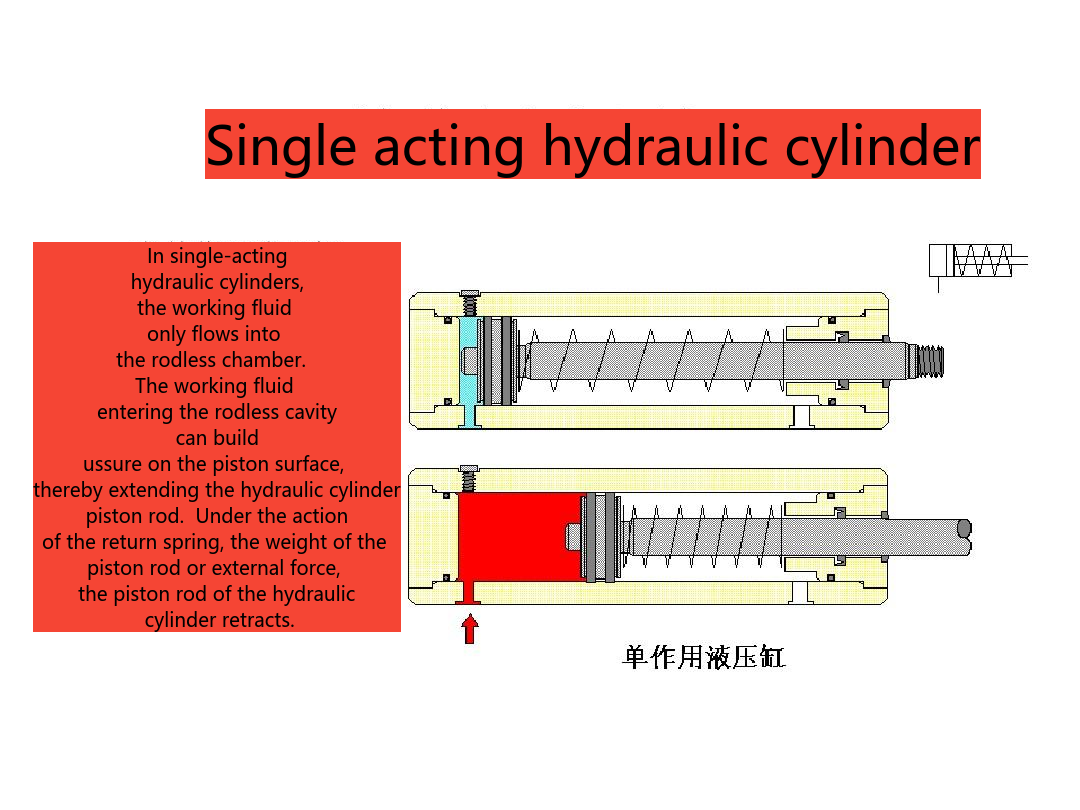

Single acting Hydraulic Cylinder

In single-acting hydraulic cylinders, the working fluid only flows into the rodless chamber. The working fluid entering the rodless cavity can build up pressure on the piston surface, thereby extending the hydraulic cylinder piston rod. Under the action of the return spring, the weight of the piston rod or external force, the piston rod of the hydraulic cylinder retracts.

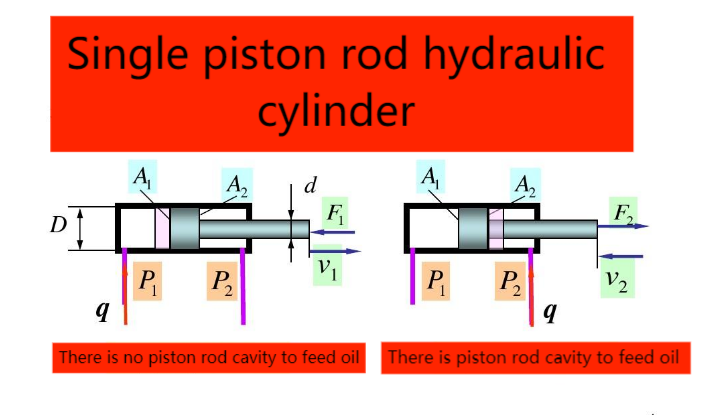

Single piston rod hydraulic cylinder

Single piston rod hydraulic piston with only one end of the piston rod, the two-way movement of the piston can obtain different speed and output force, you can refer to the schematic diagram on the left, oil circuit connection mode

PRODUCT SPECIFICATIONS

|

1

|

Cylinder tube OD:35mm - 2200mm

|

|

2

|

Cylinder tube ID:20mm - 2000mm

|

|

3

|

Cylinder tube materials: 20# 45#(CK45) 16Mn (ST52) 25Mn 27SiMn

|

|

4

|

Wall thickness : 3mm - 150 mm

|

|

5

|

Standard: GB/T 87 13-88 GB/T 3639 - 2000 TIN 2391 EN 10305

|

|

Mechanical properties

|

|

|

||

|

Steel grade

|

tensile strength (бb N/mm2)

|

Yield strength (бs N/mm2)

|

||

|

20#

|

≥520

|

≥470

|

||

|

45#(CK45)

|

≥600

|

≥520

|

||

|

16Mn

(ST52)

|

≥600

|

≥520

|

||

|

25Mn

|

≥600

|

≥510

|

||

|

27SiMn

|

≥800

|

≥720

|

||

|

Mechanical properties

|

|

|

||

|

Steel grade

|

Elongation (δ%)

|

Hardness (HB)

|

||

|

20#

|

≥12

|

175

|

||

|

45#(CK45)

|

≥12

|

207

|

||

|

16Mn

(ST52)

|

≥12

|

190

|

||

|

25Mn

|

≥15

|

195

|

||

|

27SiMn

|

≥10

|

230

|

||

|

Product Description

|

|

|

||

|

Processing form

|

Cylinder ID (mm)

|

length (m)

|

||

|

Cold drawn

|

30-250

|

≤13m

|

||

|

Precision rolling

|

40-800

|

≤13m

|

||

|

Honing

|

40-800

|

≤7m

|

||

|

Burnished

|

40-400

|

≤7m

|

||

|

Product Description

|

|

|

|

|||

|

Processing form

|

Straingt-ness (mm/m)

|

Tolerance on ID

|

Rough-ness (µ/m)

|

|||

|

Cold drawn

|

0.2-0.5

|

H9-H11

|

0.8-1.6

|

|||

|

Precision rolling

|

0.2-0.3

|

H7-H9

|

0.2-0.4

|

|||

|

Honing

|

0.2-0.3

|

H7-H9

|

0.4-0.8

|

|||

|

Burnished

|

0.2-0.3

|

H8

|

≤0.4

|

|||

|

Dimension Tolerence

|

|

|

|

|

|

|||||

|

Size of ID (mm)

|

ID Tolerance

|

|

|

|

|

|||||

|

|

H7

|

H8

|

H9

|

H10

|

H11

|

|||||

|

30

|

+0.021

0

|

+0.033

0

|

+0.052

0

|

+0.084

0

|

+0.130

0

|

|||||

|

>30-50

|

+0.025

0

|

+0.039

0

|

+0.062

0

|

+0.100

0

|

+0.160

0

|

|||||

|

50-80

|

+0.030

0

|

+0.046

0

|

+0.074

0

|

+0.120

0

|

+0.190

0

|

|||||

|

80-120

|

+0.035

0

|

+0.054

0

|

+0.087

0

|

+0.140

0

|

+0.220

0

|

|||||

|

120-180

|

+0.040

0

|

+0.063

0

|

+0.100

0

|

+0.160

0

|

+0.250

0

|

|||||

|

180-250

|

+0.046

0

|

+0.072

0

|

+0.115

0

|

+0.185

0

|

+0.290

0

|

|||||

|

250-315

|

+0.052

0

|

+0.081

0

|

+0.130

0

|

+0.210

0

|

+0.320

0

|

|||||

|

315-400

|

+0.057

0

|

+0.089

0

|

+0.140

0

|

+0.230

0

|

+0.360

0

|

|||||

Our Advantages

1.We are a powerful manufacturer integrating factory and trade

2.We have advanced production equipment ,precise measuring instruments,complete production lines,sincere service attitude

3.Specializing in the production of hydraulic products of various specifications and materials, including hydraulic cylinders, cold-drawn tubes, precision-rolled tubes, honing tubes, rolled tubes, piston rods, balance cranes, hydraulic accessories and a series of hydraulic products for more than 20 years, there are Professional technical team, service team, production team, tailor-made first-class quality, perfect products and sincere service for every customer!

Product Technical And Equipment

We have ourselves factory.All equipment all are study by ourselves.and almost machine all are new equipment,such as honed tube machine,burnished tube machine,CNC machine,Lathe machine,Welding Machine,Strightness Machine,Cutting machine,Polish machine ,and so on;Meanwhile,we have precision instrument to measuring all goods to warranty all customer requirement and quality ;

We have big factory to saperate every areas to put all goods , like cutting areas,CNC process areas,dril hole areas,welding areas,honing areas,skived and burnished areas,raw materials areas,finished surface areas,insepction areas,mounted areas,storage areas,shipping area,etc.at same time,for all product our workers will do best steps ,include grinding ,bored driling welding honing,burnishing ,cutting,measuring,warranty every steps to do that ,in case of lost something;

Professional technical team, design team support, we use professional 3D simulation software, for each customer's requirements will be tested and simulation test, everything meet customer requirements, quality is also up to standard in the case of the corresponding detection, until everything is no doubt, in the warehouse, waiting for delivery;

SIMILAR PRODUCTS

Cold drawn tube

Precision rolled tube

Honed tube

Skived and burnished Tube

Chrome plated rod

Air cylinder

Oil cylinder block

Gantry crane

Balance crane

Excavator crane

Piston rod

E355 Steel tube

Factory Power

High quality guarantee

1. 7*24 service

2.Competitive price

3.Professional technical team

4.Perfect after-sales service system

5.Can make all kinds of materials and specifications tube as customer require

6.Strong tube production capacity to ensure fast delivery

7.Guarantee Quality. Every process must be inspected, all products need be tested before leaving the factory

(1) Surface Roughness Test

(2) Ultrasonic Flaw Detector Test

(3)Chrome Thickness Test

(4) Leeb Hardness Test

(5)Coordinate Measuring Test

(6)Inner diameter Test

(7)Out Diameter Test

(8) Length Test

(9) Straightness Test

(10) Others complete Test etc.

Hot Searches