- Product Details

- {{item.text}}

Quick Details

-

Mask Material:

-

Non-woven Fabrics

-

Brand Name:

-

RECYCLE

-

Place of Origin:

-

Henan, China

-

Power:

-

8500 W

-

Dimension(L*W*H):

-

4269mm*2788mm*2022mm

-

Weight:

-

950 KG

-

Year:

-

2023

-

Technology:

-

Automation

-

Capacity:

-

120-140pcs/min of mask making machine

-

Name:

-

Mask Making Machine

-

Final products:

-

Disposable Face Masks

-

Working Process:

-

Automatic of mask machine

-

Color:

-

Silver

-

Application:

-

Mask making

-

Function:

-

Disposable Non Woven Mask Making Machine

-

Raw material:

-

Non-Woven Fabric

-

Type:

-

Non-woven Equipment

Quick Details

-

Voltage:

-

110V, 220V

-

Production Capacity:

-

120-140 pcs/min

-

Mask types:

-

Flat

-

Mask Material:

-

Non-woven Fabrics

-

Brand Name:

-

RECYCLE

-

Place of Origin:

-

Henan, China

-

Power:

-

8500 W

-

Dimension(L*W*H):

-

4269mm*2788mm*2022mm

-

Weight:

-

950 KG

-

Year:

-

2023

-

Technology:

-

Automation

-

Capacity:

-

120-140pcs/min of mask making machine

-

Name:

-

Mask Making Machine

-

Final products:

-

Disposable Face Masks

-

Working Process:

-

Automatic of mask machine

-

Color:

-

Silver

-

Application:

-

Mask making

-

Function:

-

Disposable Non Woven Mask Making Machine

-

Raw material:

-

Non-Woven Fabric

-

Type:

-

Non-woven Equipment

Technical Parameters

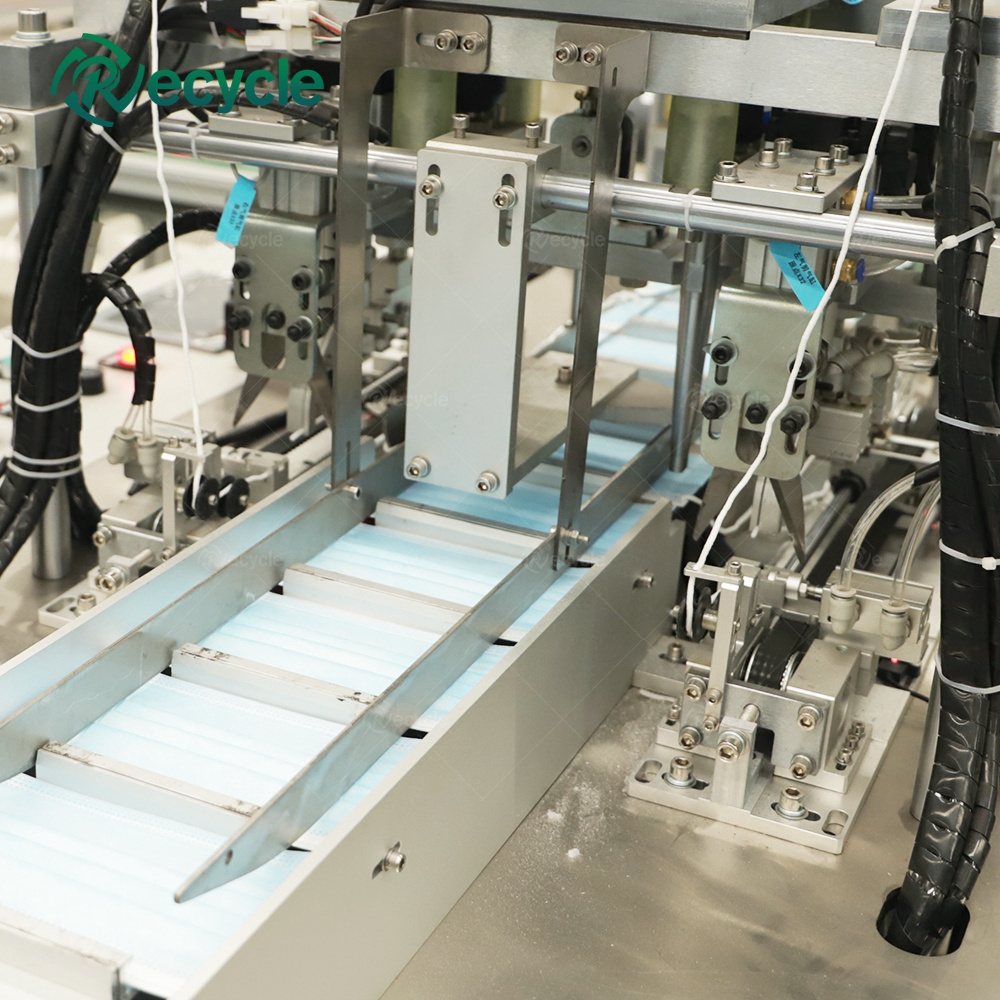

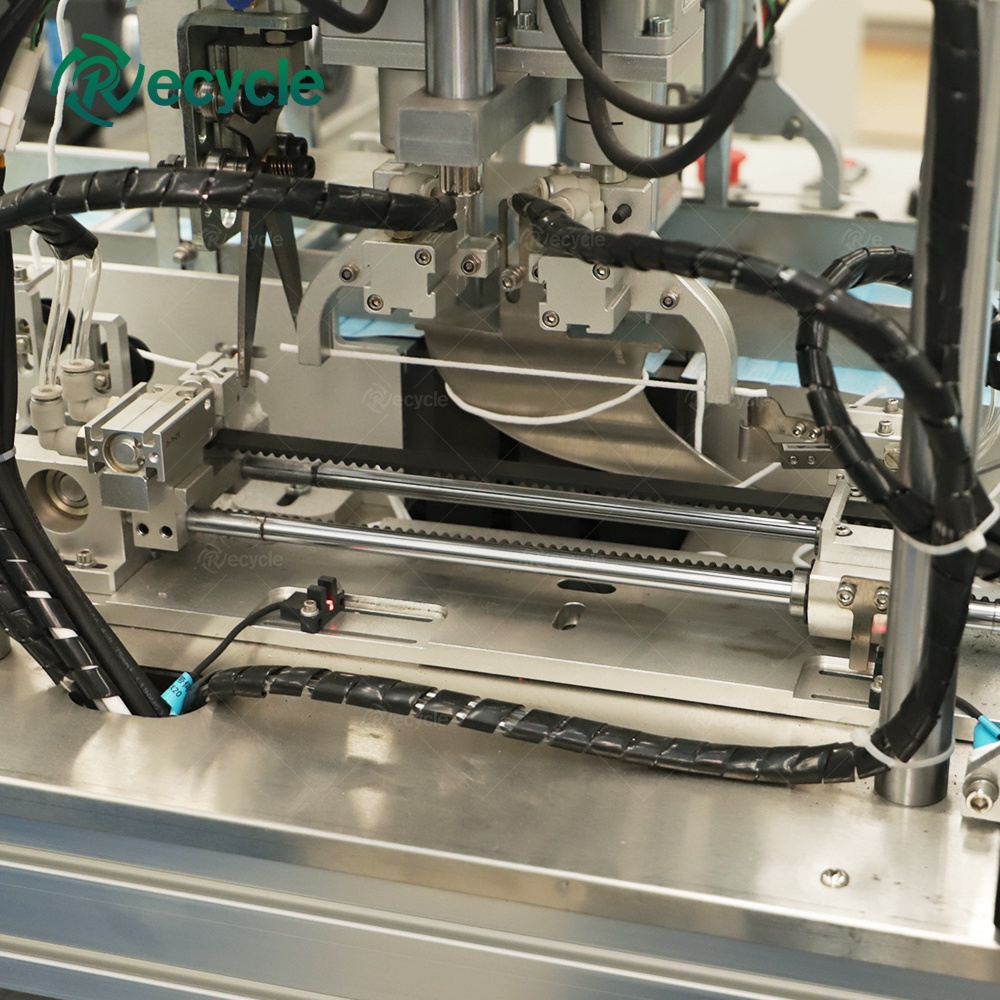

The face mask machine will finish all the processing from the feeding to nose-clip fixing, edge sealing,

cutting the finished products automatically, complete line include 1 set mask making machine and 1 set

automatic ear loop welding machine. With the new generation of mask machine equipment, the number

of cylinders used is reduced, and motors are used instead, so that the failure rate is greatly reduced and

the production efficiency rises linearly.

cutting the finished products automatically, complete line include 1 set mask making machine and 1 set

automatic ear loop welding machine. With the new generation of mask machine equipment, the number

of cylinders used is reduced, and motors are used instead, so that the failure rate is greatly reduced and

the production efficiency rises linearly.

|

Model

|

ZYPK-60

|

|

|

Capacity

|

120-140pcs/min

|

|

|

Power

|

8.15KW

|

|

|

Voltage

|

220V±5%,50/60HZ

|

|

|

Net Weight

|

1050KG

|

|

|

Mask Layer

|

2-4Plys

|

|

|

Dimension

|

4269mm*2788mm*2022mm

|

|

|

The above parameters and configuration is for reference only, specific configuration by mutual agreement shall prevail.

|

|

|

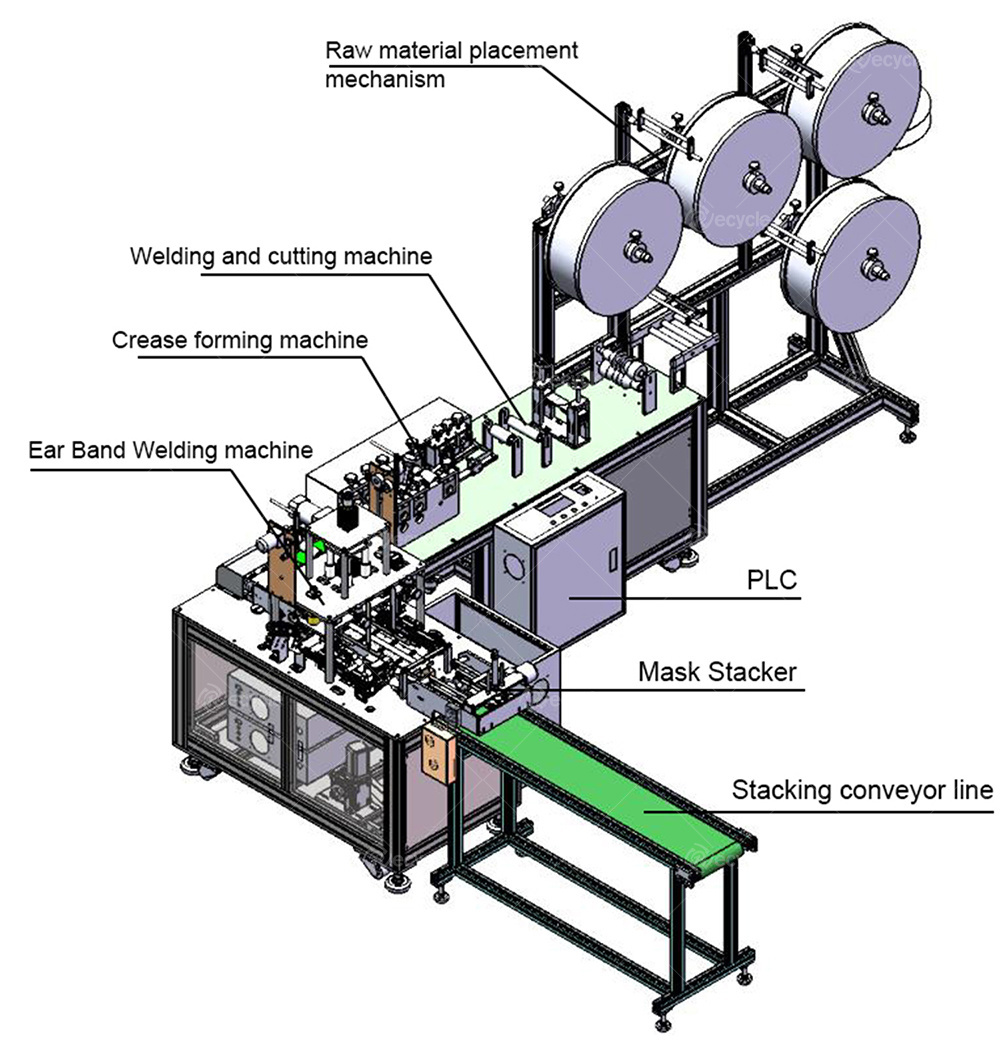

Product Structure

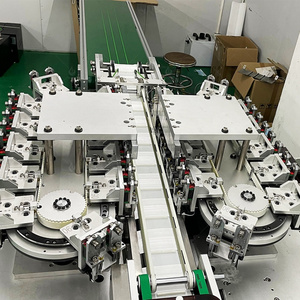

This machine is mainly used for the automatic making of flat masks: the whole roll of fabric is driven by

rollers after unwinding, and the fabric is automatially folded and hemmed; Bridge of nose strip whole roll

traction uroll,cut to length and guide into hemmed fabric. Two sides Ultrasonic welding to the seal, then

ultrasonic 2 ends sealing, cutting and shaping by a cutter; conveying the mask to the two mask ear band

welding stations through an assembly line, and finally forming the mask by ultrasonic welding; when the

mask is made, it is transported to the flat belt line for collection.

rollers after unwinding, and the fabric is automatially folded and hemmed; Bridge of nose strip whole roll

traction uroll,cut to length and guide into hemmed fabric. Two sides Ultrasonic welding to the seal, then

ultrasonic 2 ends sealing, cutting and shaping by a cutter; conveying the mask to the two mask ear band

welding stations through an assembly line, and finally forming the mask by ultrasonic welding; when the

mask is made, it is transported to the flat belt line for collection.

PLC has three languages to choose

from, Chinese, English and another

language you want to choose.

the whole blank production process is

fully automatic, and the ultrasonic

welding roller can customize logo.

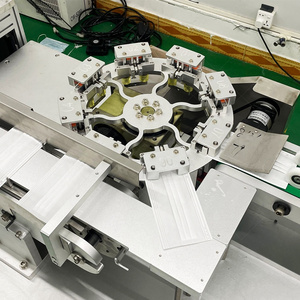

EAR LOOP

WELDING MACHINE

The welding structure of the new ear

strap adopts double guide rails for

horizontal welding and multiple servo

motors for driving, so the welding speed

is fast and stable, and the qualifed rate

of the mask is over 98%.

servo motor, customer can customize

the number of stacks.

WHY CHOOSE US

1. CE certified product and test machine with materials before delivery

CE certified products, Before leaving the factory, all machines must be debugged with materials to reach the normal trial production status, and the goods can be delivered only after the customer's remote video acceptance (domestic friends orthird-party organizations' on-site acceptance)

2. Provide equipment drawings

We will provide electrical drawings, installation drawings for equipment placement, videos and documents for solving common machine failures, so as to facilitate customers' later installation and debugging.

3. Good after-sales service

In addition to providing equipment installation videos for customers, we will set up a service team for customers about after-sales needs, including the company's manager, sales manager, engineers, customers and other relevant personnel, so that we can answer

customers'

any questions at any time. These online guidance services are completely free.

DELIVERY

Our products are packed in vacuum inside and wooden cases outside. Customers marvel at the quality of our equipment when they receive the goods. The equipment is of great weight

and the packaging is very professional.

Certificates

Company Show

Our Company has advanced technology, professional R&D team and perfect sales service system. Besides, we possess several patents and domestically-leading technologies. Our advanced equipment have been currently exported to USA, Spain, Turkey, Italy, Vietnam,Hungary, Australia, Korea, Malaysia, Singapore, India, Philippines, Ireland, Saudi Arabia, Dubai etc.

Hot Searches