Processing capacity: 1t/h

It has its own emulsification pump and self-priming pump, which has two functions of batching and emulsification, and can realize rapid mixing system equipment of liquid and solid. The equipment adopts advanced high-shear and emulsification technology to quickly and accurately homogenize and mix heterogeneous materials in a small space, resulting in fine, uniform and stable product production results.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Customized

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

Customized

-

Application:

-

Dairy Products

-

Final product:

-

Cheese/Milk/Yogurt

-

Function:

-

Heating+Pasteurizing+Fermentation+cooling

-

Usage:

-

Dairy Product Production Line

-

Material:

-

Stainless Steel

-

Processing:

-

Mixing + Pasteurizing+Freezing+Homogenizing +To

-

Capacity:

-

500-10000L

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

SURE

-

Voltage:

-

220V/380V/Customized

-

Power:

-

Customized

-

Weight:

-

500 KG

-

Dimension(L*W*H):

-

Customized

-

Application:

-

Dairy Products

-

Final product:

-

Cheese/Milk/Yogurt

-

Function:

-

Heating+Pasteurizing+Fermentation+cooling

-

Usage:

-

Dairy Product Production Line

-

Material:

-

Stainless Steel

-

Processing:

-

Mixing + Pasteurizing+Freezing+Homogenizing +To

-

Capacity:

-

500-10000L

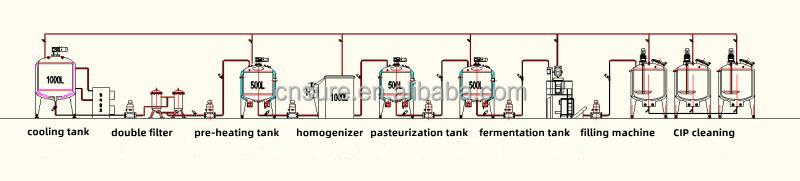

Product Overview

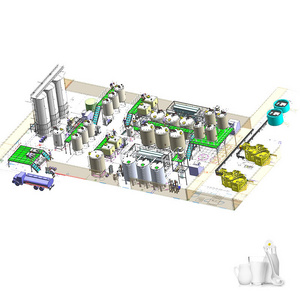

Customized Cheese/Yogert Making Production Line

FEATURES AT A GLANCE

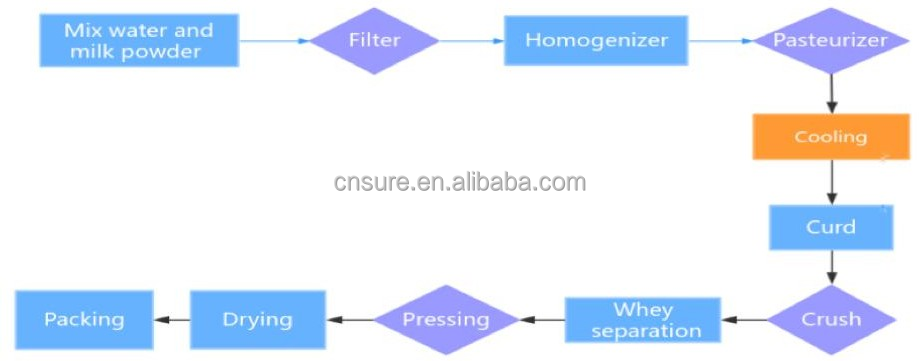

1.Water and dry powder mixing

2.Filter

Material: SUS304 stainless steel

2. Filter area: 0.15 ㎡

3. Filter aperture: customized

4. Working pressure: ≤0.2MPa

2. Filter area: 0.15 ㎡

3. Filter aperture: customized

4. Working pressure: ≤0.2MPa

3.Homogenizer

Material: Sus304

Maximum pressure 25(mpa)

Rated pressure 0-20(MPa)

Power: 7.5KW

Maximum pressure 25(mpa)

Rated pressure 0-20(MPa)

Power: 7.5KW

4.Pasteurizer

Installation size:1600*1300*2100

Tank diameter:1100

Tank outer diameter:1250

Stirring speed:36r/min

Sterilization time:10-30min (adjustable

Sterilization temperature:60-99 degrees (adjustable)

Heating cycle;60 minutes

Support part material: stainless steel screw + adjusting nut Engineering plastic :adjustable height

Power: 380V 60HZ

Heating power:48kw

Stirring power:0.75kw

Stirring method: wall scraping and stirring

Tank diameter:1100

Tank outer diameter:1250

Stirring speed:36r/min

Sterilization time:10-30min (adjustable

Sterilization temperature:60-99 degrees (adjustable)

Heating cycle;60 minutes

Support part material: stainless steel screw + adjusting nut Engineering plastic :adjustable height

Power: 380V 60HZ

Heating power:48kw

Stirring power:0.75kw

Stirring method: wall scraping and stirring

5.Temporary storage tank

1.Material: SUS304

2. Stirring motor: 0.75KW

3. Stirring speed: 36r/min

4. Fully enclosed design, upper and lower design, mirror polished inner wall, built-in temperature detection, quick opening manhole, CIP cleaning head

5. Installation size: φ1100*2000mm

6. Tank structure: single layer

7. Upper and lower tapered head structure

2. Stirring motor: 0.75KW

3. Stirring speed: 36r/min

4. Fully enclosed design, upper and lower design, mirror polished inner wall, built-in temperature detection, quick opening manhole, CIP cleaning head

5. Installation size: φ1100*2000mm

6. Tank structure: single layer

7. Upper and lower tapered head structure

6.Vat

1. Capacity: 1000L

2. Material: 304 material

3. Tank: 1200*1000*3mm

4. Inside: 1300*900*3mm

5.Outside: 1400*1000*2mm

6. Motor: 380V-2.2kw-36r/min cutting mixing

7. Electric heating: 36KW or steam heating

8. Structure: three layers with heating and insulation

2. Material: 304 material

3. Tank: 1200*1000*3mm

4. Inside: 1300*900*3mm

5.Outside: 1400*1000*2mm

6. Motor: 380V-2.2kw-36r/min cutting mixing

7. Electric heating: 36KW or steam heating

8. Structure: three layers with heating and insulation

7.

Whey filter tank

Material SUS304 2mm, single-layer rectangular tank, open, bottom route whey drain ditch, with punched mesh plate, whey drain valve

Comes with a set of material boxes

Comes with a set of material boxes

8.Press machine

Overall dimensions: 920*920*1360mm

Number of cylinders: 2

Features: Air pressure forming

Weight: 50KG

Number of cylinders: 2

Features: Air pressure forming

Weight: 50KG

9.

CIP cleaning system

It can ensure the cleaning effect, save operation time, improve work efficiency, save energy, steam and other

energy; high level of automation, extend the service life of production equipment.

energy; high level of automation, extend the service life of production equipment.

Specification Sheet

|

1

|

Milk collection system

|

|

2

|

Milk tank

|

|

3

|

Refrigerated milk storage tank

|

|

4

|

Cream Separator/Milk Cleaner

|

|

5

|

Pasteurizer

|

|

6

|

Homogenizer

|

|

7

|

Temporary storage tank

|

|

8

|

Cheese trough

|

|

9

|

Draining table

|

|

10

|

Press machine

|

|

11

|

CIP Washing System

|

|

12

|

Centrifugal pump

|

|

13

|

Electronic control system

|

Recommend Products

Customer Photos

Hot Searches