Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RuiJie

-

Voltage:

-

380V50Hz or customized

-

Dimension(L*W*H):

-

19*2.5*3m

-

Power (kW):

-

215

-

Weight:

-

15000 KG

-

Length of machine:

-

19m

-

Port:

-

Qingdao port ,China

-

Application of products:

-

outdoors park

-

Raw material:

-

PE PP granule

-

Automatic Grade:

-

fully automatic

-

Power:

-

160kw

-

Marketing Type:

-

Ordinary Product

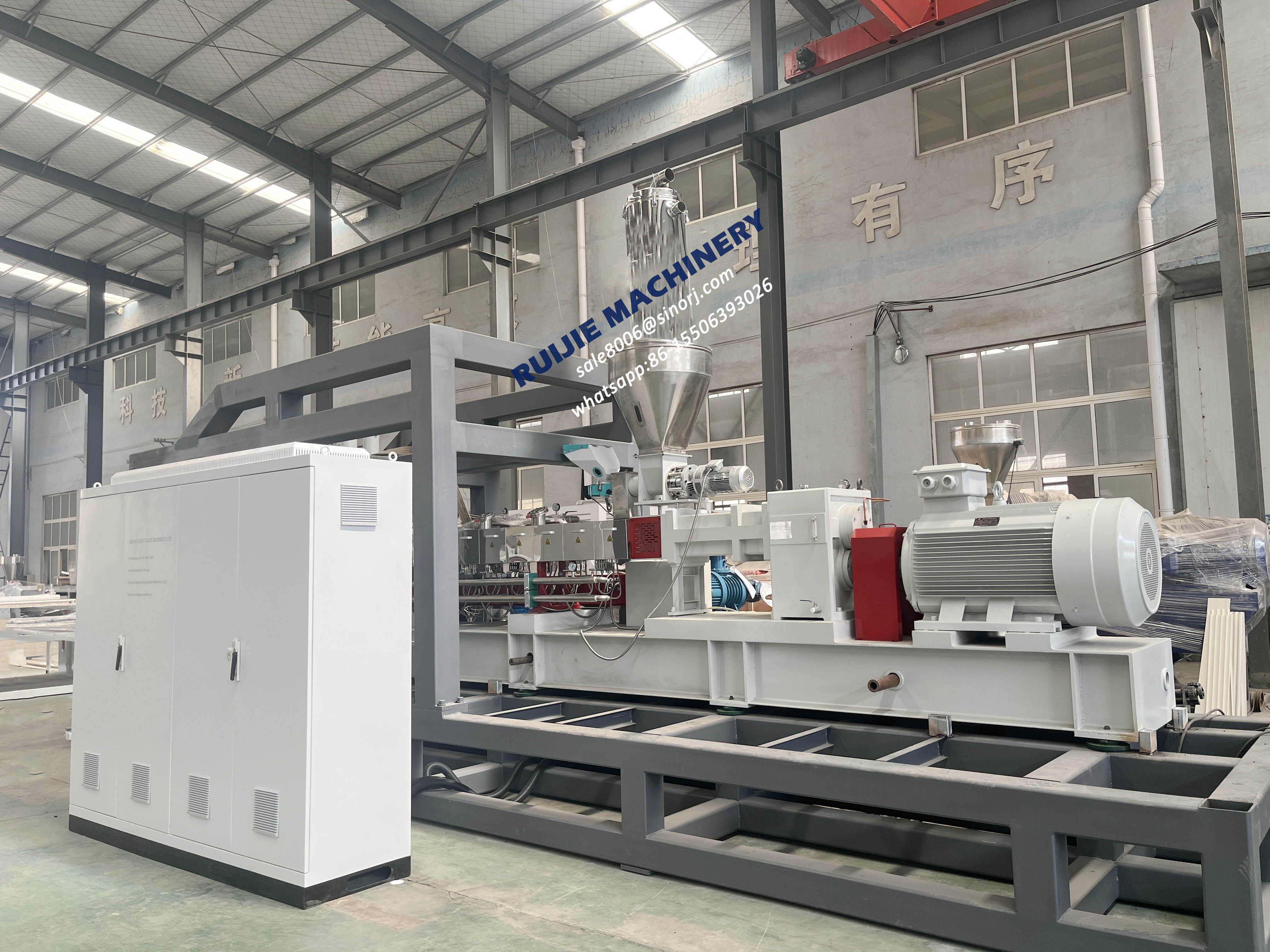

Quick Details

-

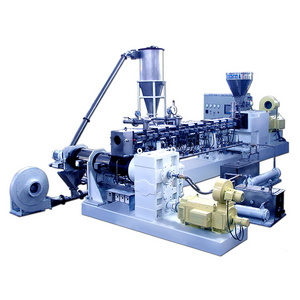

Screw Design:

-

Parallel twin extruder

-

Screw L/D Ratio:

-

35:1

-

Screw Speed (rpm):

-

72.5 rpm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

RuiJie

-

Voltage:

-

380V50Hz or customized

-

Dimension(L*W*H):

-

19*2.5*3m

-

Power (kW):

-

215

-

Weight:

-

15000 KG

-

Length of machine:

-

19m

-

Port:

-

Qingdao port ,China

-

Application of products:

-

outdoors park

-

Raw material:

-

PE PP granule

-

Automatic Grade:

-

fully automatic

-

Power:

-

160kw

-

Marketing Type:

-

Ordinary Product

Product Overview

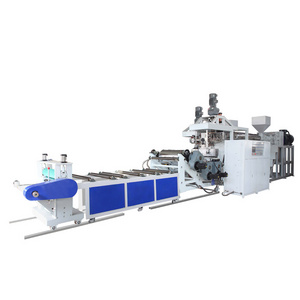

PP PET SHEET EXTRUSION MACHINE LINE

1. High capacity, about 400-550Kg/h(for SJ130 single screw) or 500kg/h(for

75 Co-Rotating parallel twin screw extruder

)

2. Energy saving: 20% energy saving than normal machines

3. The operation fully reflects the man-machine engineering principle, it can make the function more entirely and the operation more simple.

4. Equipped with mold temperature control, stainless pump body, precision temperature-controlling from room temperature to 300℃,and temperature accuracy within ±1℃ exactly in controlling temperature, quickly in heating, good in keeping temperature, long life and save time and energy.

2. Energy saving: 20% energy saving than normal machines

3. The operation fully reflects the man-machine engineering principle, it can make the function more entirely and the operation more simple.

4. Equipped with mold temperature control, stainless pump body, precision temperature-controlling from room temperature to 300℃,and temperature accuracy within ±1℃ exactly in controlling temperature, quickly in heating, good in keeping temperature, long life and save time and energy.

FEATURES AT A GLANCE

|

No

|

Machine Composition

|

Unit

|

|

1

|

75 Co-Rotating Parallel Twin Screw Extruder

|

1 set

|

|

2

|

Mould

(include metering pump and screen changer)

|

1 set

|

|

3

|

Three Roller Calender

|

1 set

|

|

4

|

Temperature Controller For Calender

|

1 set

|

|

5

|

Cooling Bracket ,Edge Cutting Device And Waste Edge Winding Device

|

1 set

|

|

6

|

Dual Surface Silicone Oil Coating And Oven

|

1 set

|

|

7

|

Haul-Off Machine

|

1 set

|

|

8

|

Double / Four Station Winder

|

1 set

|

PRODUCT CONFIGURATION

1.EXTRUDER

2.MOULD

3.THREE ROLLERS CALENDER

4.

Cooling Bracket

5.

Dual Surface Silicone Oil Coating And Oven

6.

Haul-Off Machine

7. Four Station Winding Machine

FINAL PRODUCT APPLICATION

Company Details Info

Hot Searches