- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6000*1100*2500mm

-

Weight:

-

500 KG

-

Model Name:

-

Sand Screening Machine

-

Mesh Size:

-

8mm

-

Capacity:

-

50-80m3/h

-

Sieve Size:

-

2700*1000mm

-

Hopper Size:

-

2700*1100mm

-

Belt Conveyor Width:

-

500mm

-

Power:

-

6.7kw

-

Applition:

-

Mining,construction

-

Pay Terms:

-

TT,Western Union, Credit Card, PayPal

-

Shipping terms:

-

DHL,FEDEX,TNT,UPS,By air, By sea

Quick Details

-

Type:

-

Circular

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

wkd

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

6000*1100*2500mm

-

Weight:

-

500 KG

-

Model Name:

-

Sand Screening Machine

-

Mesh Size:

-

8mm

-

Capacity:

-

50-80m3/h

-

Sieve Size:

-

2700*1000mm

-

Hopper Size:

-

2700*1100mm

-

Belt Conveyor Width:

-

500mm

-

Power:

-

6.7kw

-

Applition:

-

Mining,construction

-

Pay Terms:

-

TT,Western Union, Credit Card, PayPal

-

Shipping terms:

-

DHL,FEDEX,TNT,UPS,By air, By sea

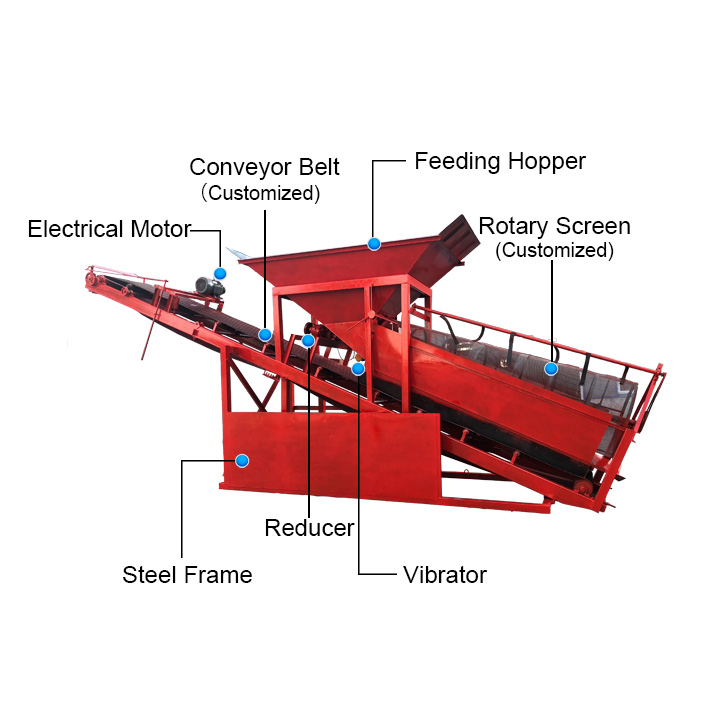

Products Description

Sand screening machine is used to separate fine and big material. It is a professional machine for screening and separating various mixed materials such as sand, coal, sediment,

etc. It is divided into electric screening engine and diesel screening engine according to power system.

etc. It is divided into electric screening engine and diesel screening engine according to power system.

It has the advantages of simple structure, large workload, low production cost and convenient maintenance, widely used in construction, highway, sand farm, building materials, mining and other industries.

Working Principles for rotary drum screen machine

1. The whole equipment of the cylindrical trommel screening machine is composed of feeding hopper, raw material feeding belt conveyor, flat screen mesh, finished sand pile material belt, and abandon stone discharge trough.

2. After the equipment is energized, the loader will load the raw materials.

3. Into the large-capacity storage hopper, the raw material is put into the flat sieve cylinder through the feeding belt, and the rotating sieve cylinder drives the raw material to form the artificial sieve effect of the raw material sliding on the screen

surface.

4. Under the pushing and tumbling of the inner blade of the cylinder, the finished sand falls on the finished sand belt through the collecting hopper, and is lifted down by the belt into a finished material pile or directly into the storage hopper.

5. The whole process is continuous and the material classification is clear and accurate.

2. After the equipment is energized, the loader will load the raw materials.

3. Into the large-capacity storage hopper, the raw material is put into the flat sieve cylinder through the feeding belt, and the rotating sieve cylinder drives the raw material to form the artificial sieve effect of the raw material sliding on the screen

surface.

4. Under the pushing and tumbling of the inner blade of the cylinder, the finished sand falls on the finished sand belt through the collecting hopper, and is lifted down by the belt into a finished material pile or directly into the storage hopper.

5. The whole process is continuous and the material classification is clear and accurate.

Technical Parameter

|

Technical Parameter

|

|

|

|

|||

|

Model No

|

WKD20

|

WKD30

|

WKD50

|

|||

|

Boundary Dimension

|

4.3*1.1*2.3m

|

8.2*1.6*3m

|

9.2*1.95*3.5m

|

|||

|

Power

|

6.7kw

|

12kw

|

13.7kw

|

|||

|

Hopper Size

|

2.3*1.1m

|

3.5*1.5m

|

3.8*1.6m

|

|||

|

Belt Conveyor Width

|

500mm

|

800mm

|

1000mm

|

|||

|

Screen Mesh Size

|

8mm(replaceable)

|

8mm(replaceable)

|

8mm(replaceable)

|

|||

|

Capacity

|

about 40m³/h

|

about 70m³/h

|

about 110m³/h

|

|||

|

Sieve Size

|

1.5*0.6m

|

3*0.8m

|

3.5*1.0m

|

|||

Details Images

Hopper

The hopper material is thickened and can load big capacity

Drum Screen

The structure is strong and not easy to damage, for longtime use

Belt Conveyor and Electric Control Box

Conveyor is to deliver the fine material into file. Electric control box is to control the operation

Project Case

Hot Searches