- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

0.75kw

-

Weight:

-

400kg

-

Dimension(L*W*H):

-

Model

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Popcorn

-

color:

-

customized

-

motor:

-

electric motor or diesel engine

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Joycan

-

Model Number:

-

JC series

-

Voltage:

-

380V/50HZ

-

Power:

-

0.75kw

-

Weight:

-

400kg

-

Dimension(L*W*H):

-

Model

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Popcorn

-

color:

-

customized

-

motor:

-

electric motor or diesel engine

-

Certification:

-

ISO

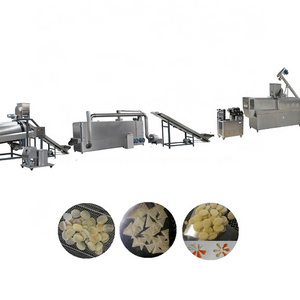

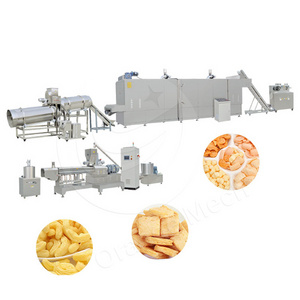

Usage and Features

It is a machine with largest puffing capacity in China heated by liquid gas, and is mainly used for dairy products such as soybean, corn, rice, wheat etc.. With large productivity and low energy consumption, it is strictly tested before leaving the factory which ensures high security rate, thus it became the first choice among domestic puffing food producers.

Operating process :

(1) Only skillfully trained man can operate the machine.

(2) Lubricate transmission parts and check whether there’s any loosen of parts before production every shift. (3) Preheat empty tank to temp. 100℃ (actual tank temp. is around 150~160℃ ) then stop the machine before first puffing, Mix puffing material with 50g edible Talcum powder (material should meet follow requirements: No impurities, no grits, water content ≤ 10%) and put mixed material into tank.

(4) Adhere to following process during operation:

Loading material process : Loading material – put on cover – capping – switch on the machine - ignition

Attention: Time for above process cannot exceed 15 sec., or material will be over-heated and adhered to tank wall.

Loading material: Push handle on the right side of the machine outward, rotate left-side handwheel to make the tank tilt to 45° , put in material and cover the cap, rotate switching level then rotate handwheel inverse direction to original position, right-side lock device will lock tank body sway automatically. Use a special socket wrench to tight capping device screw (never over-tighten it for fear that life-time of h igh temperature gasket will be shortened) before turn on the machine and iginiton.

Adjust power switch every 3-4min. during heating process to make sure an even heat of material. Turn down the power to half 2 to 3 minutes before discharging the material .

(5) Choose suitable pressure according to material (generally 8kg for rice and 10kg for corn), time for above pressure is usually 6-8min. Puffing appearance and extent during this period is will be the best.

(6) Discharging material process: Load buffer tray beneath tank mouth- turn off heating – stop the machine – locking – puffing. Make sure that there ’ s nobody in front of puffing position and operator should stand at the right side of the machine. U se special wrench to rotate handlewheel. Loose the belt and clean the residue material immediately after puffing, then can go on production.

It is very important for material discharging, make no mistakes!!!

in parameters of explosion-puffing

|

Name of grain |

Puffing temp. / ℃ |

Puffing pressure /MPa |

Puffing rate |

|

Corn |

190-225 |

0.6-0.75 |

95% |

|

Soybean |

190-220 |

0.6-0.7 |

100% |

|

Glutinous rice |

170-180 |

0.6-0.7 |

95% |

|

Peanut |

170-200 |

0.4-0.6 |

100% |

|

Rice |

180-200 |

0.75-0.8 |

100% |

|

Mung bean |

140-180 |

0.7 |

95% |

|

Sorghum rice |

185-210 |

0.75-0.8 |

95% |

|

Yellow rice |

180-210 |

0.75-0.8 |

95% |

|

Broad bean |

185-250 |

0.75-0.8 |

85% |

|

Potato chips |

180-220 |

0.6-0.8 |

Flowerless |

|

Sweet potato |

170-220 |

0.6-0.8 |

Flowerless |

|

Corn dreg |

190-225 |

0.75-0.8 |

95% |

|

Sesame |

250-270 |

0.75-0.8 |

Flowerless |

|

Sunflower seed |

200-230 |

Normal pressure |

Flowerless |

|

Paddy hull |

180-220 |

Normal pressure |

Golden color |