- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380/440/660V

-

Power:

-

190-1000KW

-

Dimension(L*W*H):

-

Depending on Model

-

Weight:

-

500000 kg, 100-900tons

-

Diameter:

-

2m - 5.2m

-

Quality:

-

High Level

-

Name:

-

Rotary Kiln

-

Installation:

-

Under Technical Guidance

-

Kiln Type:

-

Horizontal Kiln

-

Color:

-

As required

-

Factory Visit:

-

Welcome

-

Spare parts supply:

-

Available

-

Length:

-

As required

Quick Details

-

Marketing Type:

-

New Product 2024

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Zhengzhou Sinoma

-

Voltage:

-

380/440/660V

-

Power:

-

190-1000KW

-

Dimension(L*W*H):

-

Depending on Model

-

Weight:

-

500000 kg, 100-900tons

-

Diameter:

-

2m - 5.2m

-

Quality:

-

High Level

-

Name:

-

Rotary Kiln

-

Installation:

-

Under Technical Guidance

-

Kiln Type:

-

Horizontal Kiln

-

Color:

-

As required

-

Factory Visit:

-

Welcome

-

Spare parts supply:

-

Available

-

Length:

-

As required

Product Description

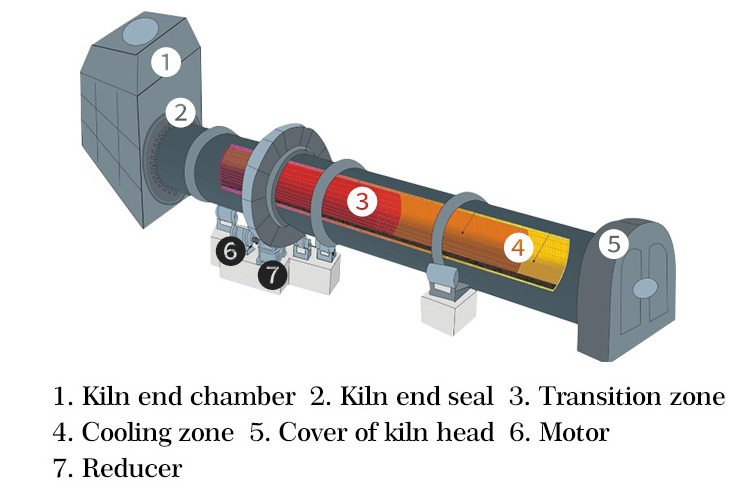

Rotary kiln

is the main equipment for calcining cement clinker,which is mainly used in cement production line. The applicable materials include limestone, calcium carbonate, copper ore and other materials.It’s widely used in chemical industry, metallurgy, etc.

Details Images

Features:

1. The rotary kiln can process materials such as kaolin, lime, cement, zinc oxide, bauxite and ores, it is an important calcining equipment.

2. Large capacity, 1000-6000 t/d, suitable for different enterprises;

3. High calcining efficiency and good production quality.

4. The rotary kiln adopts an electrified control operation system, convenient to operate.

5. Good environmental protection measures.

Product Paramenters

|

Model

|

Diameter

(m)

|

Length

(m)

|

Capacity

(t/d)

|

Kiln Speed

(r/min)

|

Motor Power

(kw)

|

Total Weight

(t)

|

|

Ф3.2x50

|

3.2

|

50

|

1000

|

0.398-3.975

|

190

|

235

|

|

Ф3.3x52

|

3.3

|

52

|

1200

|

0.391-3.91

|

190

|

281

|

|

Ф3.5x54

|

3.5

|

54

|

1650

|

0.43-4.3

|

220

|

334

|

|

Ф4.0x60

|

4

|

60

|

2500

|

0.396-3.96

|

315

|

487

|

|

Ф4.2x60

|

4.2

|

60

|

2800

|

0.4165-4.165

|

420

|

576

|

|

Ф4.3x64

|

4.3

|

64

|

3200

|

0.449-4.49

|

450

|

585

|

|

Ф4.5x66

|

4.5

|

66

|

4000

|

0.41-4.1

|

560

|

710

|

|

Ф4.7x72

|

4.7

|

72

|

5000

|

0.45-4.5

|

710

|

825

|

|

Ф4.8x72

|

4.8

|

72

|

5000

|

0.403-4.03

|

630

|

847

|

|

Ф4.8x74

|

4.8

|

74

|

5000

|

0.35-4.0

|

630

|

841

|

|

Ф5.0x60

|

5

|

60

|

5500

|

0.4-4

|

710

|

787

|

|

Ф5.2x61

|

5.2

|

61

|

6000

|

0.38-3.79

|

800

|

859

|

* Note:

The capacity may vary with different materials and feeding sizes. Technical parameters are subject to change without notice.

Application Areas&Materials

Application:

1. Cement industry: Calcining cement clinker, the main equipment of cement manufacturing.

2. Metallurgical industry: roasting metal ores such as iron ore and sulfide ore to obtain the required metal elements.

3. Chemical industry: calcine active lime, high alumina stone, aluminum sulfate and other chemical raw materials.

4. Ceramic industry:

remove moisture and organic matter from ceramic raw materials to dry and sinter the raw materials.

5. Environmental protection: Dispose of solid waste such as hazardous waste, medical waste, and sludge.

Packing & Delivery

Hot Searches