source water tank--water pump--silica sand filter-- active carbon filter-- sodium-- ion exchanger-- precision filter

--reverseosmosis system-- uv sterilizer --Ozone sterilizer --pure water tank

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99.5%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sky Machine

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

2500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

6000-8000bph

-

Bottle Material:

-

PET

-

Usage:

-

Mineral Water, Pure Water, Beverage

-

Bottle size:

-

200ml-2000ml

-

Machine material:

-

Stainless Steel SUS 304

-

Control:

-

PLC

-

Processing:

-

Washing,filling,capping

-

Processing Types:

-

Small Water Bottling Machine

-

Product name:

-

Small Business Water Filling Machine

Quick Details

-

Machinery Capacity:

-

4000BPH, 6000BPH, 2000BPH, 1000BPH

-

Packaging Material:

-

Plastic, Glass

-

Filling Material:

-

Water

-

Filling Accuracy:

-

99.5%

-

Voltage:

-

220V/380V

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Sky Machine

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

2500 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Capacity:

-

6000-8000bph

-

Bottle Material:

-

PET

-

Usage:

-

Mineral Water, Pure Water, Beverage

-

Bottle size:

-

200ml-2000ml

-

Machine material:

-

Stainless Steel SUS 304

-

Control:

-

PLC

-

Processing:

-

Washing,filling,capping

-

Processing Types:

-

Small Water Bottling Machine

-

Product name:

-

Small Business Water Filling Machine

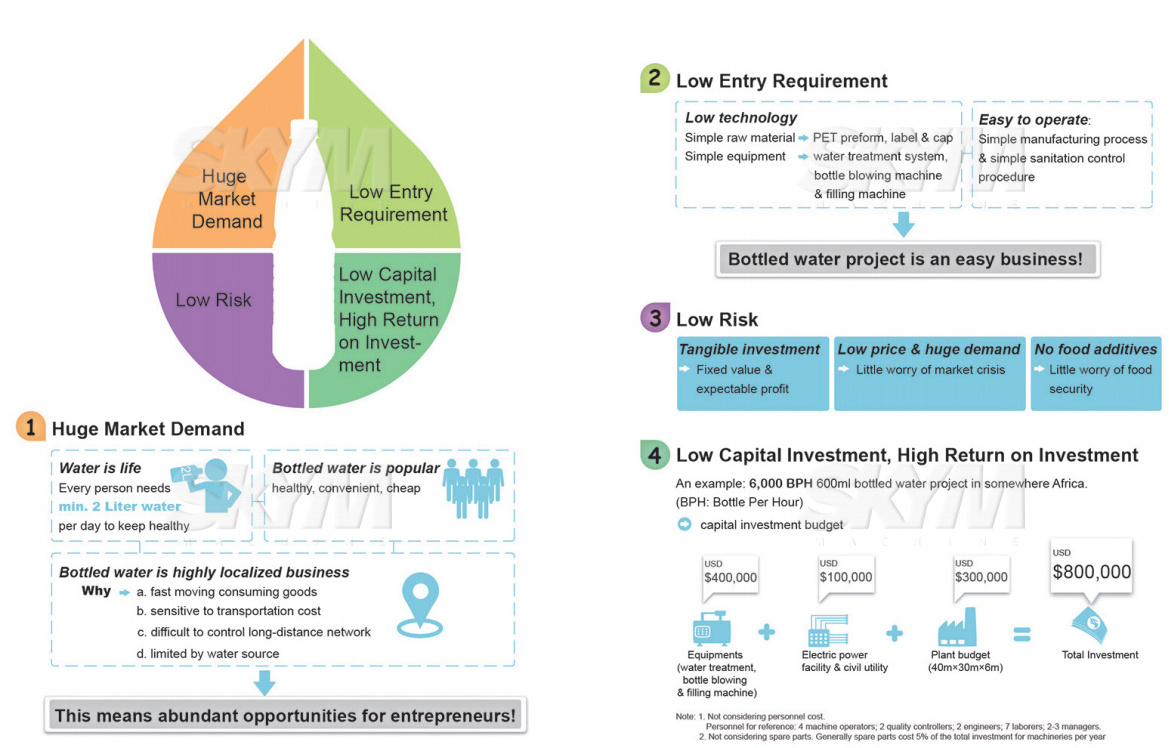

Why Invest In Bottled Water?

Small Manufacturing Bottle Drinking Water Filling Machines For Small Business Ideas

The machine is used for producing drinking water in PET bottle, such as pure water, mineral water,natural water etc.Adopting hanging-neck technology,it can transfer the plastic bottle more stably and faster. One machine can finish washing bottle, filling and capping three processes, sanitary and high-efficiency,High-quality filling valve guarantee the filling level precision.

Beverage Machinery-Equipment characteristics:

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough..

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company.

Washing Part

● Into bottle way is air conveyor direct connection with bottle dial.● All 304/316 stainless steel rinse heads, water spray style

inject design, more save water consumption and more clean.

● 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

● 304/316 stainless steel washing pump make the machine more durable.

inject design, more save water consumption and more clean.

● 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

● 304/316 stainless steel washing pump make the machine more durable.

Filling Part

● 304/316 Stainless steel high precision filling nozzle

● Filling volume adjustable in fine rank, same liquid level after filling

● All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

● 304/316 stainless steel filling pump

● Efficient spray nozzle rinse thoroughly and save water for flushing

● Filling volume adjustable in fine rank, same liquid level after filling

● All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

● 304/316 stainless steel filling pump

● Efficient spray nozzle rinse thoroughly and save water for flushing

Capping Part

● Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

● All 304/316 stainless steel construction

● No bottle no capping

● Automatic stop when lack of bottle

● Capping effect is stable and reliable, Defective rate ≤0.2%

● All 304/316 stainless steel construction

● No bottle no capping

● Automatic stop when lack of bottle

● Capping effect is stable and reliable, Defective rate ≤0.2%

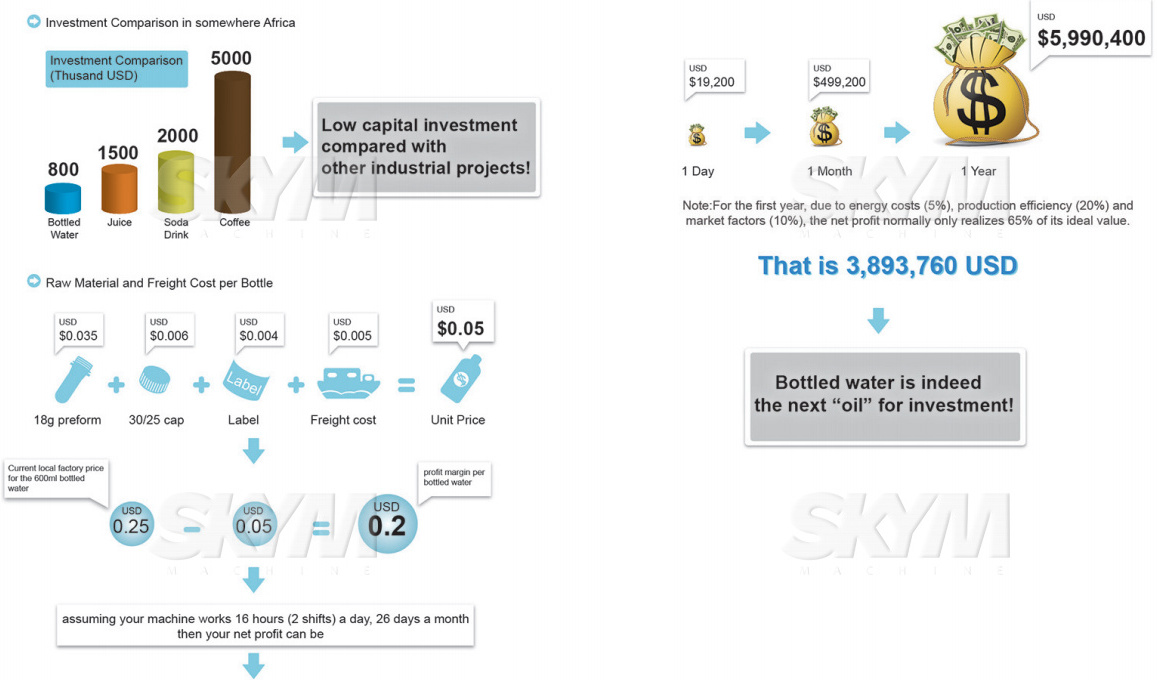

Investment Profit Analysis Form

How Can Comprehensive Solutions Help In Brand Building?

Customized Bottle Design

Product Parameters

|

Model

|

CGF8-8-3

|

CGF14-12-5

|

CGF16-16-5

|

CGF24-24-8

|

CGF32-32-10

|

CGF40-40-12

|

CGF50-50-15

|

|

Capacity (BPH)

|

1000-2000

|

3000-5000

|

6000-8000

|

8000-12000

|

12000-15000

|

16000-20000

|

20000-24000

|

|

Power supply

|

2.2kw

|

2.42 KW

|

3.12 KW

|

3.92 KW

|

3.92 KW

|

5.87 KW

|

7.87 KW

|

|

Overall dimension

|

1830x160x2050

|

2360×1770×2700

|

2760×2060×2700

|

2800×2230×2700

|

3550×2650×2700

|

4700×3320×2700

|

5900×4150×2700

|

|

Weight (KG)

|

2100

|

2500

|

3500

|

4200

|

5500

|

6800

|

7600

|

Real Picture Of Customer Factory

Related Products

Water Treatment System

Automatic PET Bottle Blow Molding machine

Automatic blowing machine adopts our most advanced blowing technologies. This machine is a fully automatic,high intelligent,stable

and reliable blowing machine,with simple structure,and low energy consumption. It is very popular and well used in food

,beverages,cosmetics,pharmaceutical industry.

and reliable blowing machine,with simple structure,and low energy consumption. It is very popular and well used in food

,beverages,cosmetics,pharmaceutical industry.

Automatic PVC shrink labeling machine

Application: PVC / PET / OPS label sleeve

* Stainless steel Main Machine Frame / Famous electrical components

* Stainless steel Main Machine Frame / Famous electrical components

Automatic PE film shrink wrapping machine

This machine is suitable for wrapping and packaging of such products as pop-top, mineral water, bottles beer, drinks etc without bottom-tray(or with bottom-tray). Working with PE shrink tunnel to pack the goods perfectly. The whole producing of shrink wrapping machine process adopt the Germany advanced

technology

. And the main parts of shrink wrapping machine are imported from international famous companies, capability stable and using long-time.

ABOUT SKYM

Zhangjiagang Sky Machine Co.,Itd is located at Leyu Economic Development Zone of Zhangjiagang City.Our Company was founding

in 2008.We committed to do the World’s most competitive liquid drink packaging manufacture suppliers.Focus on providing customers with safe,energy,saving,efficient equipment.And high quality,fast and personalized service. We sincerely invite businesses around the world to bulid a professional relationship with us based on trust,benefits and the promising possibility for future development.

in 2008.We committed to do the World’s most competitive liquid drink packaging manufacture suppliers.Focus on providing customers with safe,energy,saving,efficient equipment.And high quality,fast and personalized service. We sincerely invite businesses around the world to bulid a professional relationship with us based on trust,benefits and the promising possibility for future development.

Hot Searches