- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

5.5m x 5.5m x 12.33m

-

Weight:

-

5.8t

-

Key Selling Points:

-

Easy to install

-

Name:

-

Used cement silo tank

-

Usage:

-

wood ash cement silo storage

-

Materials:

-

carbon steel

-

Production standard:

-

Chinese standard

-

Brand name:

-

Shelley cement silo

-

Silo type:

-

Assembly type cement silo structure

-

Quality certificate:

-

ISO BV CE

-

Silo Materials:

-

carbon steel

-

Certification:

-

CE ISO SGS

-

Installation Type:

-

assembly

Quick Details

-

Core Components:

-

Water-proof Silo Roof

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

TSE

-

Dimension(L*W*H):

-

5.5m x 5.5m x 12.33m

-

Weight:

-

5.8t

-

Key Selling Points:

-

Easy to install

-

Name:

-

Used cement silo tank

-

Usage:

-

wood ash cement silo storage

-

Materials:

-

carbon steel

-

Production standard:

-

Chinese standard

-

Brand name:

-

Shelley cement silo

-

Silo type:

-

Assembly type cement silo structure

-

Quality certificate:

-

ISO BV CE

-

Silo Materials:

-

carbon steel

-

Certification:

-

CE ISO SGS

-

Installation Type:

-

assembly

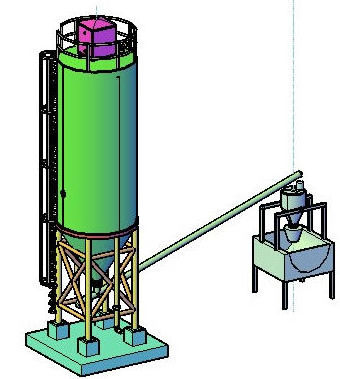

wood ash cement cimento storage silo tank

wood ash cement cimento storage silo tank is widey used to storage cement and some other powder materials.

Advantages of wood ash storage silo

1. Cement storage silo with different capacities:50T,100T,150T,200T,etc.

2. Cimento silo with customized sizing and layout to specific requirement

3. Cimento silo is substructure, easy transportation, installation fast, level display,

with positive and negative regulator,Green filter

4. Put in bulk powder (cement or fly ash), waterproof and moisture, easy to use and reduce costs ,

the top of cement silo with green filter, used to reduce dust leakage.

5. Cement silo equipped with a safety valve at the top of cement silo, cement silo used to

balance the pressure difference between inside and outside. Upper and lower parts of the cement silo

is equipped with display materials, can monitor the number of cement materials warehouse.

With gas in the lower part of broken cement storage devices, to ensure smooth unloading.

6. Cement storage silo bin is cylinder and supporting structure. The superior part has dust

removing device to avoid leakage of dust; and the inferior part is equipped with arch breaker

to avoid powder caking and make discharging smooth, and bin level sensing device to master usage

of material in the bin at any time.

7. Cement silo generally adopts bulk cement conveying truck to send powder in the bin by

pneumatic conveying; according different structures of cement bin, there are two kinds of discharging:

the first is the inferior part is connected with screw conveyer and screw conveyer send powders into

powder measure; the second is to adopt pneumatic conveying (to special cement bin).

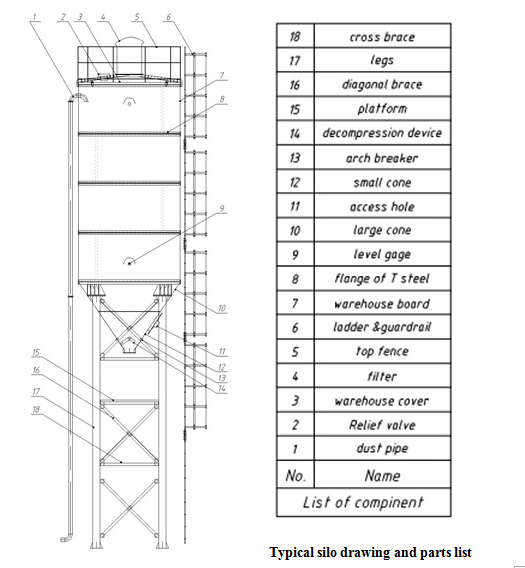

Cement silo tank structure

Cement Storage Silo Production

Cimento Silo Drawings

(the following drawing is designed by our sales, our engineer will finally give a design of your needed grain storage system in CAD format after determination )

This kind of CAD is design for you for free.

Cement silo Installation

We are always here waiting for you.