- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/220V/415V

-

Dimension(L*W*H):

-

5300x5100x2200mm

-

Motor Power (kW):

-

18KW

-

Model Number:

-

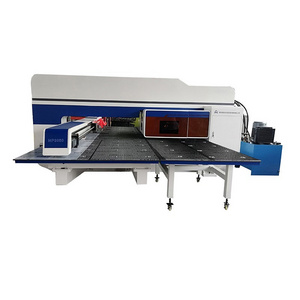

DMSFC31550 servo turret punch press

-

Weight (T):

-

12

-

Product name:

-

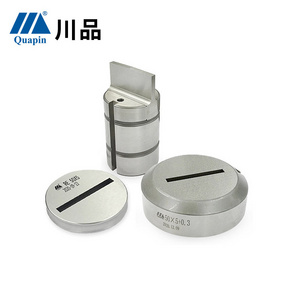

amada arcade 212 turret punch press and die tools

-

Application:

-

Metal Sheet hole punching

-

Pressure capacity:

-

300KN of amada arcade 212 turret punch press and die tools

-

Max.workpiece thickness:

-

6.35mm

-

Max.workpiece weight:

-

120kg

-

Punching precision:

-

0.1mm of amada arcade 212 turret punch press and die tools

-

Punching size:

-

1500x5000mm

-

Punching stations:

-

32 or 42 stations

-

Punching speed:

-

1500 rpm

-

Control system:

-

Cnc Control of amada arcade 212 turret punch press and die tools

Quick Details

-

Slide Stroke (mm):

-

150

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Darling Machinery

-

Voltage:

-

380V/220V/415V

-

Dimension(L*W*H):

-

5300x5100x2200mm

-

Motor Power (kW):

-

18KW

-

Model Number:

-

DMSFC31550 servo turret punch press

-

Weight (T):

-

12

-

Product name:

-

amada arcade 212 turret punch press and die tools

-

Application:

-

Metal Sheet hole punching

-

Pressure capacity:

-

300KN of amada arcade 212 turret punch press and die tools

-

Max.workpiece thickness:

-

6.35mm

-

Max.workpiece weight:

-

120kg

-

Punching precision:

-

0.1mm of amada arcade 212 turret punch press and die tools

-

Punching size:

-

1500x5000mm

-

Punching stations:

-

32 or 42 stations

-

Punching speed:

-

1500 rpm

-

Control system:

-

Cnc Control of amada arcade 212 turret punch press and die tools

amada arcade 212 turret punch press and die tools

Video link:

YouTube: https://youtu.be/w_LBkImnARo

QQ video: https://v.qq.com/x/page/w3215xq6kcm.html

Baidu video: https://haokan.baidu.com/v?vid=4796257467261552449&bfe=1

Main technology parameters

|

Pressure |

KN |

300 |

|

Max.punching diameter |

mm |

88.5 (D station) |

|

Max.workpiece thickness |

mm |

6.35 |

|

Max.workpiece weight |

Kg |

120 |

|

Punching precision |

mm |

±0.1 |

|

Resent location precision |

mm |

±0.1 |

|

Compressed air |

Mp |

0.55-0.8Mpa (Laser using air pressure is higher than 2.0Mpa) |

|

Punching frequency |

time/min |

1500 |

|

Cutting speed |

m/min |

30 (because of different material, cutting speed is based on actual work) |

|

Feeding speed |

m/min |

100m/min |

|

Punching size |

mm |

1500x5000 (including one reset ) |

|

Punching stations |

set |

32 (Thick turret length-oriented international general mold) |

|

Rotating station |

B/C |

1B, 1C |

|

Control axis |

set |

5 |

|

Turret speed |

Hpm |

30 |

|

Dimension |

mm |

5300x5100x2200 |

|

Station layout |

|

A, B, C, D (2 rotating stations) |

Main configuration

|

No. |

Name |

DMSFC31550-32 |

Note |

|

1 |

CNC system |

Punching composite professional system |

Can be upgraded to laser punching machine |

|

2 |

Body |

Closed structure, steel plate welding, Thermal aging treatment, finishing processing |

The body, crossbeam and crossbeam seat are all subjected to high-temperature heat treatment aging to ensure stability during long-term use. |

|

3 |

Turret reducer |

Casting special CNC punch reducer |

Imitation of Japanese reducer, can withstand long-term verification |

|

4 |

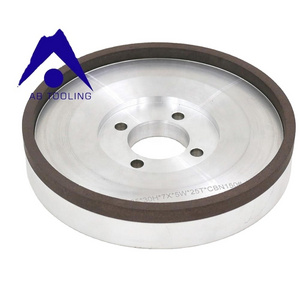

Punching stations |

National standard thick turret 24/32 station |

Up and down turret disk are of integral nodular cast iron structure. There is no screw or pin hole connection in the middle. The device will not be misaligned and deformed after many years of application. It has high stability and good guidance of the national standard thick turret. |

|

5 |

Rotating station |

The same as AMADA |

Stable structure and durable |

|

6 |

Punching range |

1500x5000mm (one time 1500x2500mm) |

Left and right size of worktable reaches 5300mm, 1500x2500mm does not need to be repositioned, and large plates can be easily processed |

|

7 |

Servo motor |

Japan, Yaskawa |

Large servo motor, high efficiency and energy saving |

|

8 |

Guide |

Taiwan PMI |

All are extended sliders, durable |

|

9 |

Ball screw |

Taiwan TBI |

Rolled large guiding ball screw is durable |

|

10 |

Servo punching head Main motor system |

Germany Vectron |

original imported |

|

11 |

punching head servo motor |

China |

Weak magnetic motor high efficiency and energy saving |

|

12 |

Planetary reducer |

France MOTOVARIO |

High-precision single-stage planetary reducer |

|

13 |

High precision rack |

Taiwan T-WIN |

3M high hardness grinding helical rack is quiet and efficient |

|

14 |

Electrical components |

Schneider, Omron |

International famous brand, high stability |

|

15 |

Pneumatic Components |

Taiwan AirTAC |

|

|

16 |

Clamp |

Three sets of floating clamps |

Deal with the deformation of the material during processing |

|

17 |

Worktable structure |

High elastic soft nylon brush surface, with air float universal ball |

The table is durable, and the surrounding stainless steel edges effectively protect the edges of the brush. The air float platform can easily cope with the positioning of thick plates, reducing the work intensity of the operator. |

|

18 |

Centralized automatic oil injection |

have |

The advanced oil supply method can ensure the lubrication of each fueling point and reduce the amount of oil used for lubricating oil |

|

19 |

Machine weight |

12500kg |

CNC system

Professional punching machine CNC control system is the latest professional industry control system, machine running reliability is improved highly.

8-1, System characteristics

8-1-1, CNC turret punch press professional system with drawing and step punching function.

8-1-2, Simple international using G code programming, operating conveniently.

8-1-3, Computer control directly, make CAD drawing directly.

8-1-4, Equipped with the most advanced digital AC servo motor and servo system.

8-1-5, Site programming, background programming.

8-1-6, Chinese and English language.

8-1-7, Key of operating panel can be defined according requirement, satisfy with client personalized design.

8-1-8, Using high speed serial data cable, less connecting cable.

8-1-9, High integration, using professional software. Less starting time, no data losing if there is sudden power off.

8-2, System Function

8-2-1, Linear axis: X and Y

8-2-2, Alarming display for many mechanical and electrical fault like over moving stroke.

8-2-3, With self-diagnose function.

8-2-4, With soft location limiting function.

8-2-5, With international using G code programming.

8-2-6, With punching mold compensation function.

8-2-7, With pitch compensation function.

8-2-8, With opposite gap compensation function.

8-2-9, With coordinate offset function.

8-2-10, With location reset function.

8-2-11, With automatic, manual and semi-automatic method.

8-2-12, With inner store locked function.

8-2-13, With parameter editing function.

8-2-14, With subprogram store and recalling function.

8-2-15, With fact locating and punching locked function.

8-2-16, With single step punching function.

8-2-17, With all kinds of M function.

8-2-18, With absolute and increasing program.

8-2-19, With jumping function in normal and abnormal situation.

8-2-20, With punching mold anti-hitting function.

8-2-21, With plate anti-hitting function.

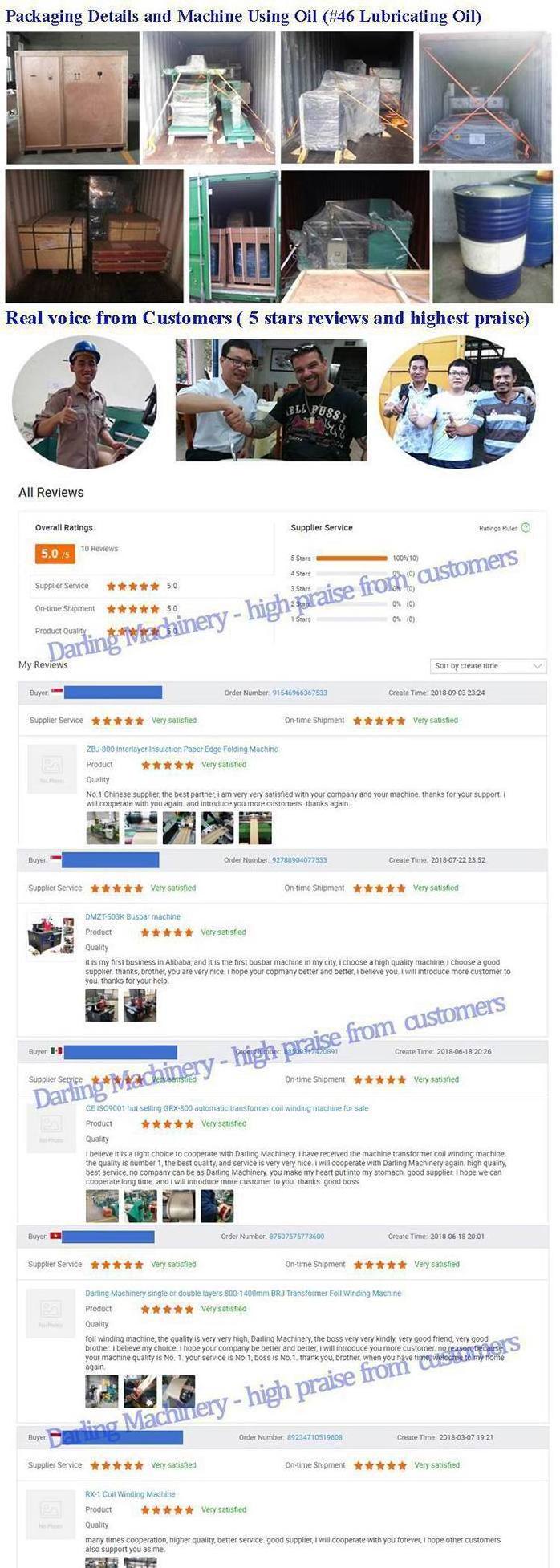

Our service

1, before sales: we will give you professional instruction and help you to buy the suitable machine, after you choose our machine, let you take the biggest profit through using our machine.

2, in sales: we will give you feedback informations about your order through photos and video. let you put your heart into stomach.

3, after sales: we will go to your factory to give you a training and teach you how to use our machine, or we will give you a video training. if there is our local agent and office, we will let our local engineer to your factory and give you a training.

4, our quality assurance: all our machine using life.

Getting Local office support, please contact with our company:

|

Shandong Darling Machinery Equipment Co., Ltd.

Add: Shacun Industry Park, Licheng District, Jinan City, China. Contact person: Martin Hoo +86-15253156158 (WhatsApp) Skype/Wechat: martinhoo936 QQ: 613252158 Website: www.darlingmachinery.com |

We will be the best partner

Although we live in different countries, our hearts are always together . We don ’ t only sell machine, we also sell service, technology and brand. One time cooperation, be friend forever!

Our cooperation is Double win results.

® Our aim is:

Through using our machine, you can make better product and earn more money !

FAQ:

1, are you manufacture or trading company?

we are manufacture more than 15 years, 3 branch factory, more than 10000 square meters.

2, how about your quality ?

we only sell high quality machine, we use the world famous brand component, like SIEMENS, MITSUBISHI, DELEM, PANASONIC, SCHNEIDER, ABB, etc. so there is no worry about our quality.

3, what about your after sales service ?

we go to your factory for site training or you can get local branch company traning, if there is no requirement, we can give you video training in other methods.

4, why do we must choose you as our supplier ?

customer real voice is your best reference, 5 stars customer feedback reviews, 100% high praise. those voice can let you to cooperate with us safely.