- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Fiberglass Mesh Raw Materials

-

Feature:

-

High Strength

-

Material:

-

E-Glass Fibre Glass

-

Usage:

-

Insulation Industry

Quick Details

-

Type:

-

E-glass

-

Place of Origin:

-

China

-

Processing Service:

-

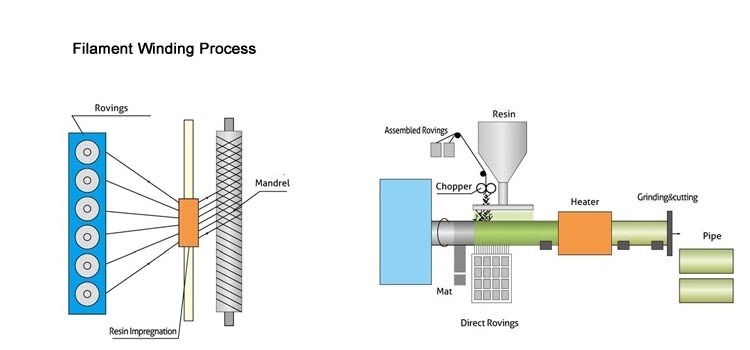

Filament Winding Process, Centrifugal Casting Process, Spray Up Process, Sheet Molding Compound Process, Chopped Strands for BMC, Extruding and Injection Molding Process, Direct Roving for LFT-D/G, ECR Glass Chopped Strands for Thermoplastics, Continuous Sheet Production Process, Chopped Strand Mat Production Process

-

Application:

-

Fiberglass Mesh Raw Materials

-

Feature:

-

High Strength

-

Material:

-

E-Glass Fibre Glass

-

Usage:

-

Insulation Industry

Free Sample For Fiberglass Roving

Since it was our first encounter, you are worried about the quality of our products, and I agree.

But I am very confident in the quality of my products because we can provide free samples for you to verify them and gain your trust and orders.

Custom Fiberglass Roving

Our factory has the ability to customize the products you want. You are required to provide detailed information about the product, such as weight, length, and whether it is used in powder or emulsion.

Products Description

Fiberglass Mesh Is Mainly Alkali Resistant Fiberglass Fabric, It Made Of The C Or E Glass Fiber Yarn (main Ingredient Is ASilicate, Good Chemical Stability) Through A Special Weaving Technique, Then Coated By The Antalkali And Reinforcing Agent And Treated By High Temperature Heat Finishing. It’s Ideal Engineering Material In Construction And Decoration.

After Surface Treatment, This Alkali-resistant Fiberglass Mesh Has Excellent Properties Including Water resistance,Alkali-resistance, Flexibility, Softness And Resistance To Aging. It Is Widely Used In Reinforcing Walls, Natural Marble, Plaster Board, Artificial Stone Materials And Exterior Insulation Finishing System. It Is Also Widely Used For Renovating Building Surface.

ECR-glass Assembled Roving for Spray Up

The assembled fiberglass roving for spray-up is coated with based sizing, compatible with unsaturated polyester and vinyl ester resins. Then it’s cut by the chopper, sprayed with the resin on the mold, and rolled, which is necessary to soak the resin into the fibers and eliminate air bubbles. In the end, the glass-resin mixture is cured into the product.

Fiberglass Mesh Feature

1. Good choppability and anti-static

2. Good fiber dispersion

3. Multi-resin-compatible, like UP/VE

4. No spring back at the small angle

5. High-intensity of the composite product

6. Excellent electric (insulation) performance

2. Good fiber dispersion

3. Multi-resin-compatible, like UP/VE

4. No spring back at the small angle

5. High-intensity of the composite product

6. Excellent electric (insulation) performance

Product number(tex):custom,300.600.800.1100.1200.2400.4800.9600.

Excellent material

High-performance glass fiber

high strength,

corrosion-resistant

long-lasting use

Wide range of uses

Used in the manufacture of FRPpipes, pressure vessels. Grating,profile and manufacture of square

cloth Later used in the manufactureof ships, chemical storage tanks.

Good

permeability

Good process performance, lesshairiness, compatible with a varietyof resins, fast and completepenetration, good mechanicalproperties of products.

Good short-cutperformance

Uniform thickness and high strengthGood craftsmanship

Fiberglass Mesh Packing & Shipping

Storage

Unless otherwise specified, it is recommended to store the fiberglass spray roving in a dry, cool and moistureproof environment where the room temperature and humidity should always be maintained at 15°C to 35°C (95°F). Fiberglass roving must remain in packaging material until just before their use.

Partial Production Process Display

ECR-Roving Process

Chopped Strand Mat Process

Woven Roving Process

Packing And Loading

Hot Searches