- Product Details

- {{item.text}}

Quick Details

-

After-sales Service Provided:

-

Video technical support

-

After-sales service:

-

Online support

-

Brand:

-

DeTe

-

Feature:

-

High Efficiency Safety Long Life

-

Certification:

-

CE

-

Size:

-

Customized Size

-

Keywords:

-

crusher shredder blade

-

Packing:

-

Wooden Packing

-

Marketing Type:

-

New Product 2022

Quick Details

-

Place of Origin:

-

Jiangsu, China, Nanjing,Jiangsu province

-

Brand Name:

-

NanjingDete

-

Weight (KG):

-

15

-

After-sales Service Provided:

-

Video technical support

-

After-sales service:

-

Online support

-

Brand:

-

DeTe

-

Feature:

-

High Efficiency Safety Long Life

-

Certification:

-

CE

-

Size:

-

Customized Size

-

Keywords:

-

crusher shredder blade

-

Packing:

-

Wooden Packing

-

Marketing Type:

-

New Product 2022

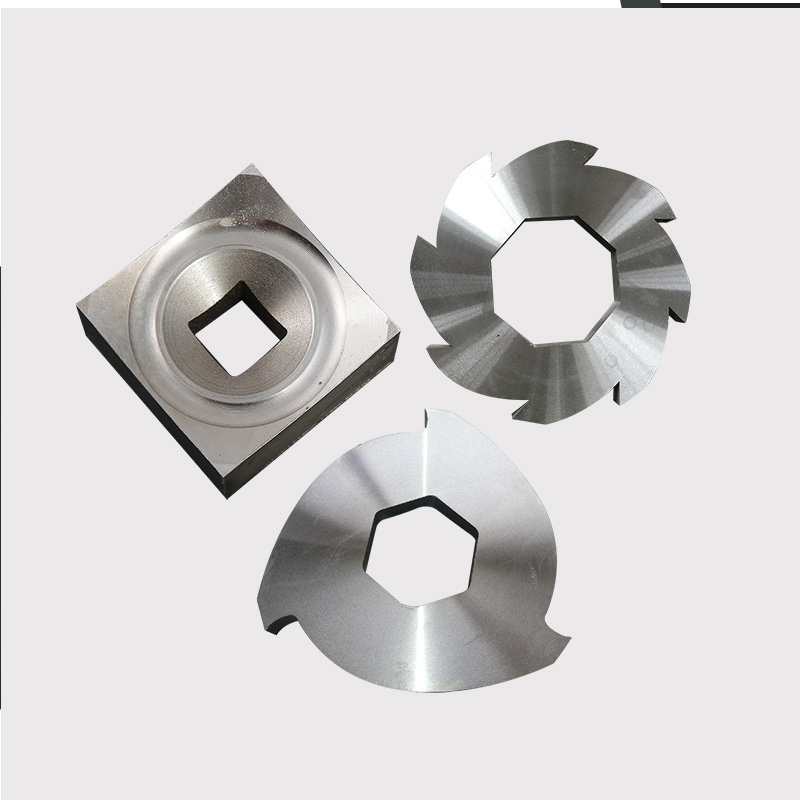

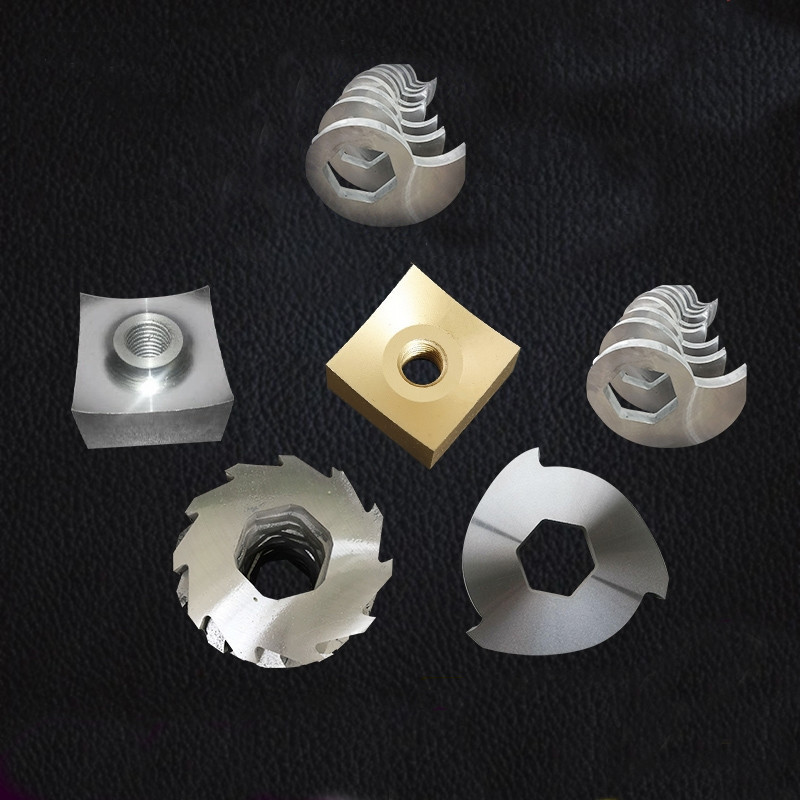

Products Description

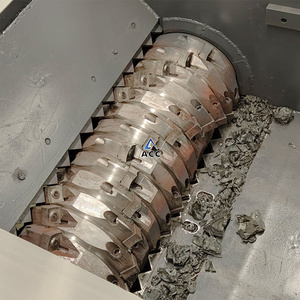

The shredder blade is an important accessory on the shredder. The quality of the shredder blade directly affects the processing cycle of the machine to the waste. According to the classification of the shredder, the shredder blade is divided into single-shaft shredder blade and shredder blade. Multi-shaft shredder blades. As an important shredding knife on the shredder.

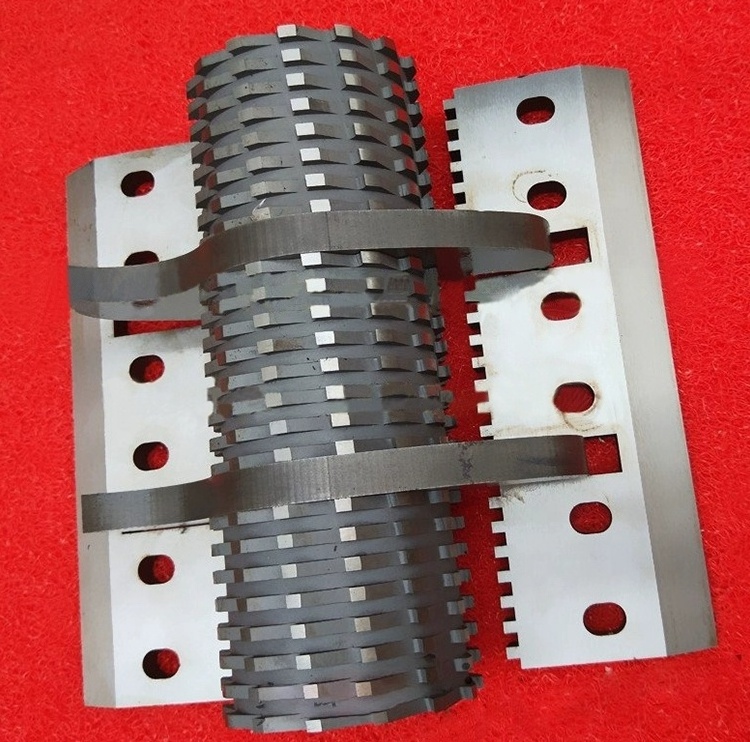

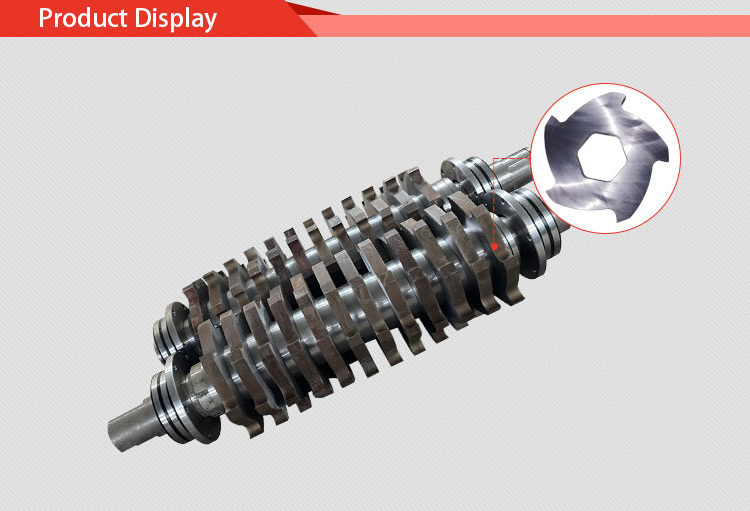

According to the structure of the shredder, the shredder blades can be divided into single-shaft shredder blades and multi-shaft shredder blades.The multi-shaft shredder blade is a claw knife, which is installed on a double-shaft or four-shaft shredder according to the design of each company. Blades, etc., are used for shredding, shredding and extrusion to reduce the size of materials. This shredder blade is used for the shredding of waste plastics, waste rubber, wood and other bulky wastes.

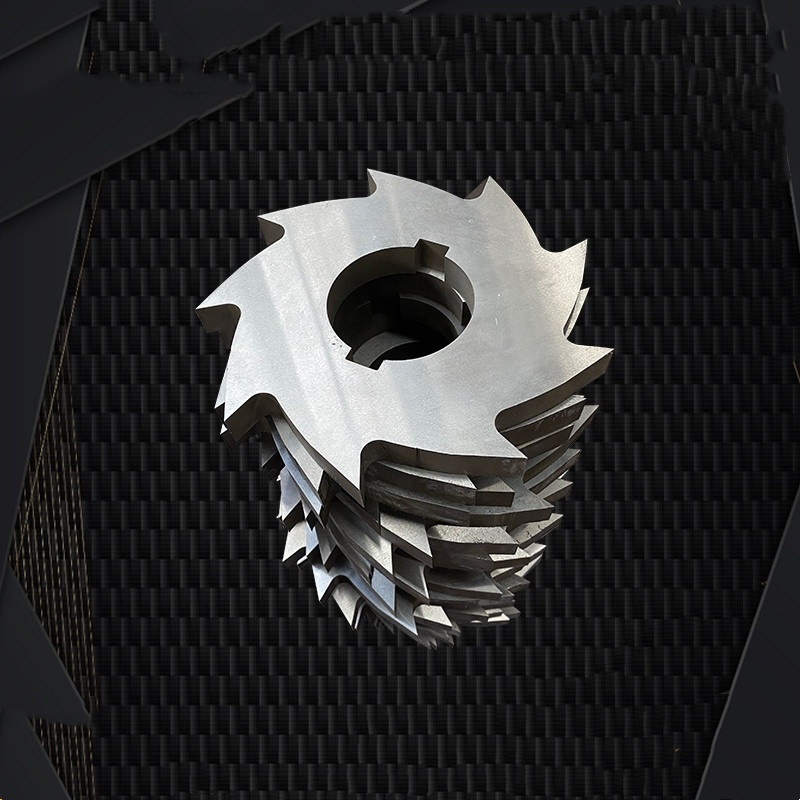

Commonly used shredder cutters have a diameter of 200mm-500mm and a thickness of 20mm-55mm. Most of the inner holes are hexagons, and they can also be made into octagons or circles (with keyways) according to customer needs. The shredder blade is quenched in salt bath furnace and vacuum furnace, which can make the hardness of various materials and specifications meet the requirements.

Product details

The material of the shredder blade is generally 9crsi, Cr12Mov, SKD-11, of which 9CrSi is alloy tool steel. This kind of material has high hardness and good wear resistance, but it is brittle. It is suitable for rubber, fiber, paper and other materials. Soft waste, Cr12MoV and SKD-11 are cold work die steels. These two materials have similar properties, with strong wear resistance and impact resistance, and are suitable for shredding wood, waste furniture, and plastics with high hardness.

Different materials are selected according to different processing objects.

Plastic industry: 42CRMO, w5SICR.SKD-11.

Metal industry: 6CRW2SI, CR12Mov, LD, H13, SKD-11, D2.

Wood industry: w5SICR, 6CRW2SI, SKH, SKD-11.

Heat treatment industry: HRC55-57.

Blade specifications

: Standard shredder blades are available from stock, non-standard tools can be customized according to customer drawings.

Blade characteristics

: The product has good wear resistance, strong impact resistance, and the cutting edge is lasting and sharp.

Manufacturing Technique

Customized requirements

: Standard blades only need to provide dimensions, and non-standard blades can be customized for production only by providing the length, width, thickness, hole size and eye distance of the blade if drawings and samples cannot be provided. From the beginning of cutting, we select the required materials in strict accordance with customer requirements. Every link from forging, roughing, heat treatment, finishing to delivery, etc., will be produced in strict accordance with technical requirements to ensure that customers can use qualified and quality-assured blades. The company has rich experience in the control of blade heat treatment hardness. Customers only need to inform the material of the product to be crushed, and we can recommend the most suitable blade hardness to ensure that the blade achieves the best state in terms of toughness and wear resistance at the same time.

Production Process

Production Process

◆1. Blanking---choose materials according to customer requirements.

◆2. Forging--Forging is mainly to increase the density of the material.

◆3. Annealing-to lower the temperature for processing.

◆4. Finishing-mainly processing the material into shape.

◆5.Inspection---inspect whether the product is consistent with the drawing sample.

◆6. Quenching-improve the corresponding hardness of the molded product and material.

◆7. Annealing--In order to increase the wear resistance of the product, it must be annealed for a long time.

◆8. Quenching and tempering-mainly the parallelism of quenched and tempered products to facilitate processing.

◆9. Coarse grinding-rough grinding of each surface of the product.

◆10. Precision grinding-super precision grinding, mirror grinding, improve the accuracy and parallelism of the product.

◆11. Inspection-Let unqualified products refuse to flow into the market.

◆12. Packing--different packing according to different products.

Hot Searches