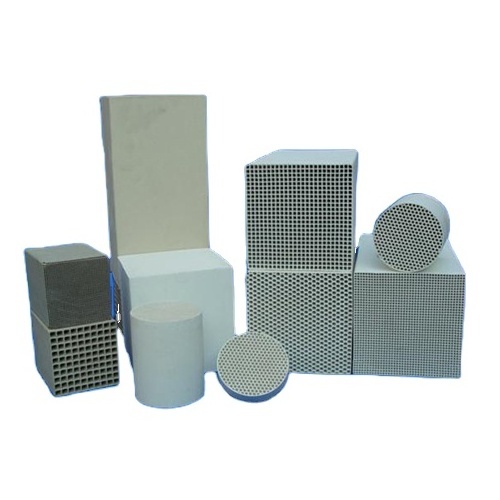

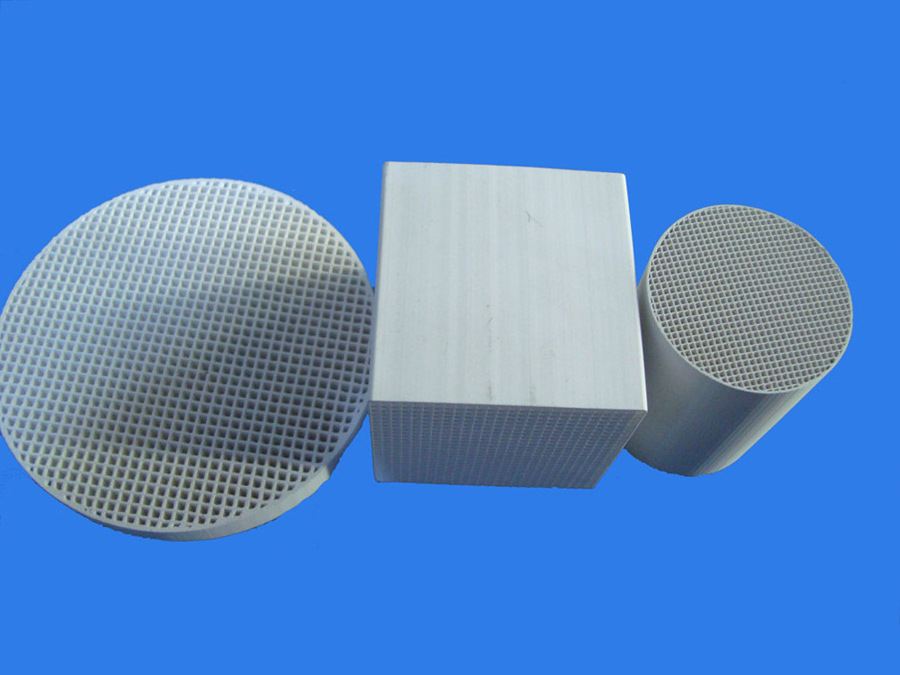

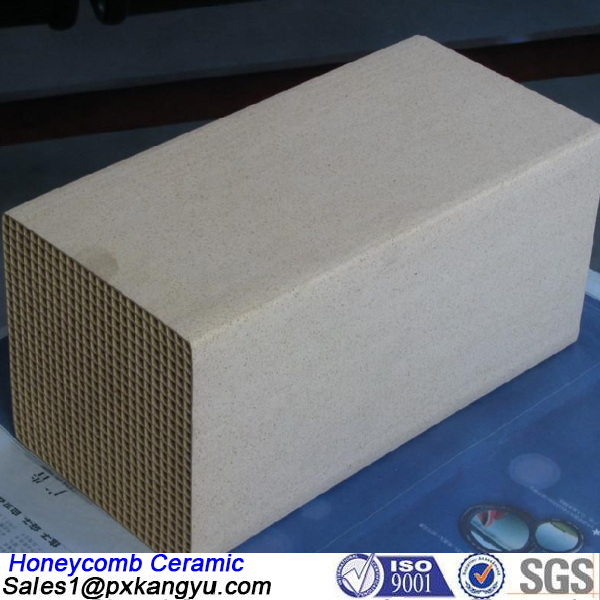

Honeycomb ceramic is a new developed porous industrial ceramic. As heat storage body, it has the properties of corrosion

resistances, large specific surface area, small heat resistance, good thermal conductivity and excellant thermal-shock resistance

performance, realize quickly exchanging heat and reducing energy, widely used in the industrial field. The honeycomb ceramic as

the heat exchange media is the key part for heat storaging HTAC ( High Temperature Air Combustion) technology. It is the best

choice for RTO, heat exchanger and other environmental protection and energy saving products.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

KANGYU

-

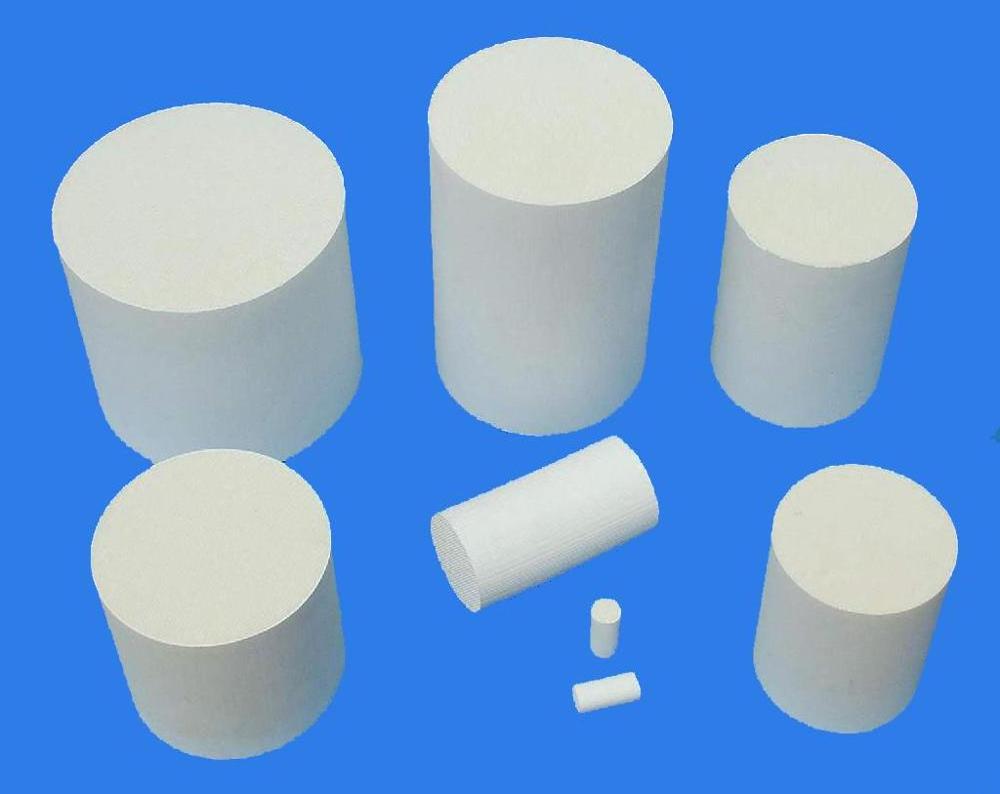

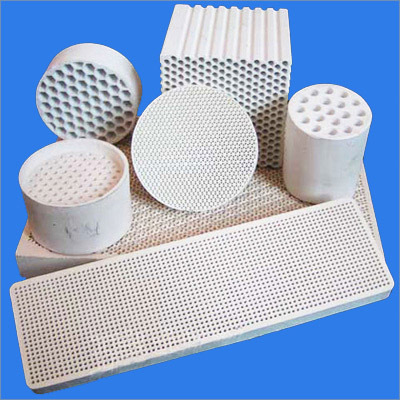

Shape:

-

Cylinder,trapezoid,oval-shaped,racetrack-shaped

-

Combustion temperature:

-

420 degree C

-

Channel Density:

-

400 cells/square inch

-

Emission Standard:

-

Euro 2 3 4 5

-

Color:

-

White

-

Product name:

-

Honeycomb Ceramic

-

Package:

-

Wooden Case

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangxi, China

-

Model Number:

-

Honeycomb Ceramic

-

Brand Name:

-

KANGYU

-

Shape:

-

Cylinder,trapezoid,oval-shaped,racetrack-shaped

-

Combustion temperature:

-

420 degree C

-

Channel Density:

-

400 cells/square inch

-

Emission Standard:

-

Euro 2 3 4 5

-

Color:

-

White

-

Product name:

-

Honeycomb Ceramic

-

Package:

-

Wooden Case

Main Features:

1. A new developed porous industrial ceramic.

2. Large specific surface area, corrosion resistance, small heat resistance, good thermal conductivity, excellant thermal-shock

resistance.

3. Thermal energy storage.

4. We can produce the honeycomb ceramic series with different shapes and sizes according to customers’ requirements.

1. A new developed porous industrial ceramic.

2. Large specific surface area, corrosion resistance, small heat resistance, good thermal conductivity, excellant thermal-shock

resistance.

3. Thermal energy storage.

4. We can produce the honeycomb ceramic series with different shapes and sizes according to customers’ requirements.

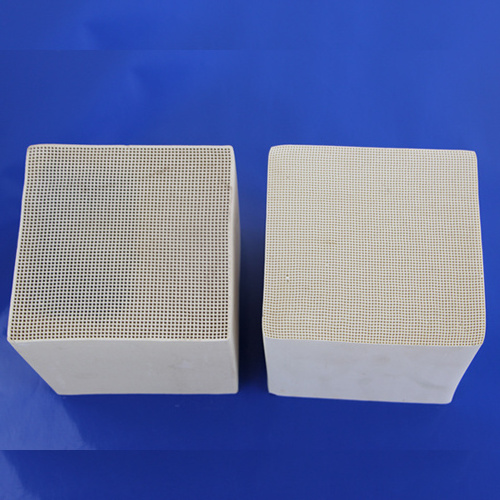

|

Dimension (mm)

|

Hole Number (mm)

|

Wall Thickness (mm)

|

Specific Surface Area

(m2/m3) |

|

150×150×300

|

25×25

|

1.0

|

573

|

|

150×150×300

|

32×32

|

0.9

|

785

|

|

150×150×300

|

40×40

|

0.7

|

883

|

|

150×150×300

|

43×43

|

0.65

|

1000

|

|

150×150×300

|

50×50

|

0.7

|

1050

|

|

150×150×300

|

60×46

|

0.5

|

1316

|

Application

all kinds of pushing-steel heating furnace, RTO ( Regenerative Thermal Oxidation), stepping heating furnace, heat

treatment furnace, forging furnace, dissolving furnace, steel wrapping/middle wrapping baking apparatus, soaking pit, radiation

tap incendiary apparatus, covering furnace, high temperature hot-blast stove in metallurgical machine building, all kinds of

ceramic cellar stove, glass cellar stove in building materials, all kinds of tap heating stove, splitting stove, other industrial

stove cellar, etc.

treatment furnace, forging furnace, dissolving furnace, steel wrapping/middle wrapping baking apparatus, soaking pit, radiation

tap incendiary apparatus, covering furnace, high temperature hot-blast stove in metallurgical machine building, all kinds of

ceramic cellar stove, glass cellar stove in building materials, all kinds of tap heating stove, splitting stove, other industrial

stove cellar, etc.

|

Index

|

Metric Unit

|

Value

|

|

Material Density

|

g/cm3

|

2.3-2.6

|

|

Average Linear Expansion

|

10-6/k-1

|

<2.5

|

|

Special Heat Capacity

|

KJ/Kg

|

900-1200

|

|

Heat Conductivity

|

W/MK

|

1.8-3.0

|

|

Max. Application Temp.

|

°C

|

1350

|

|

Acid resist strength wt.loss

|

%

|

<4

|

|

Water Absorption

|

%

|

<5

|

Note

All the data is only for reference, specific specifications, types and materials are according to customers' requirements

Not exactly what you want? Post a quick Buying Request!

Not exactly what you want? Post a quick Buying Request!

Product packaging

Pay attention!

1. The goods should be properly kept at the site to ensure no water accumulation,avoid rain, and protect it;

2. Ensure that the packaging steel drum is completely sealed without damage and leakage;

3. Avoid contact with oil to avoid contaminating the goods;

4. Steel drums must be placed upright to avoid rolling;

5. There may be a weak vacuum in the iron drum,the venting screw on the barrel should be opened first to eliminate the vacuum inside the barrel.

6. Open the venting hole and the lid before filing ,to avoid long-term exposure of the goods to the air;

7. Choose a sunny day for construction;

8. Make sure that the protective equipment of the filing personnel is completely clean to prevent the oil and impurities from contaminating the goods;

9. Check that there are no large gaps in the bed of the goods, and the gaps and holes need to be welded;

10. If the goods is not filled on the same day;all the inlet channels of the purifier must be tightly sealed;

11. After the filing is completed, sealed the inlet and outlet valves to prevent air convection.

Hot Searches