- Product Details

- {{item.text}}

Quick Details

-

MF:

-

/

-

EINECS No.:

-

618-493-1

-

Place of Origin:

-

Korea

-

Type:

-

Lubrication

-

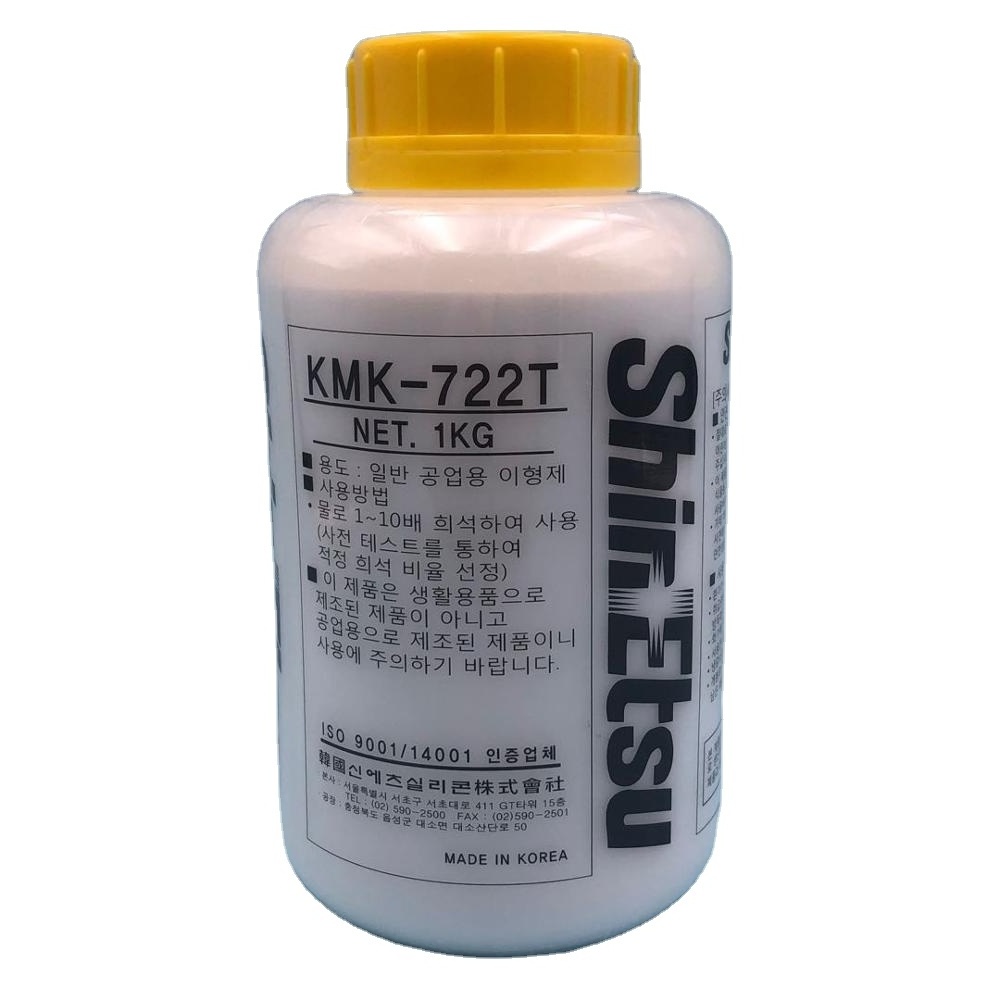

Brand Name:

-

Shin Etsu

-

Model Number:

-

KMK-722T

-

Appearance:

-

Milky White Liquid

-

Specific gravity:

-

1

-

Active ingredient:

-

30

-

pH:

-

7.0

-

Ionicity:

-

Nonionic

Quick Details

-

CAS No.:

-

63148-62-9/9016-00-6/9006-65-9

-

Purity:

-

30

-

Other Names:

-

Silicone emulsion

-

MF:

-

/

-

EINECS No.:

-

618-493-1

-

Place of Origin:

-

Korea

-

Type:

-

Lubrication

-

Brand Name:

-

Shin Etsu

-

Model Number:

-

KMK-722T

-

Appearance:

-

Milky White Liquid

-

Specific gravity:

-

1

-

Active ingredient:

-

30

-

pH:

-

7.0

-

Ionicity:

-

Nonionic

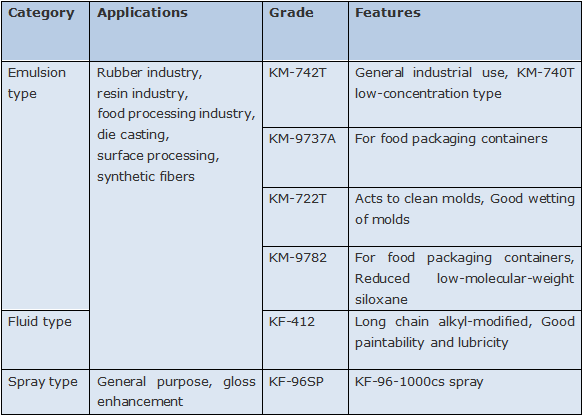

The surface tension of silicone is low and it spreads easily, so it provides good wetting of fine, irregular surfaces. It is chemically inactive and can be used with almost all molding materials. Silicone has excellent heat and cold resistance and offers good performance over a wide temperature range. These characteristics are why silicone is used as a mold-release agent in a range of industries including the rubber industry, resin industry, food processing industry, and die casting. Silicone mold-release agents are available in various forms including emulsions, fluid types, solvent types, bake-on types, and sprays.

Versatility: Can be used in diverse applications including rubbers, plastics, metals, and foods.

Mold releasability: Silicone mold-release agents are non-compatible with almost all organic materials, so they offer outstanding mold-release performance.

Heat and cold resistance: They have excellent resistance to heat and cold and provide good mold-release results over a wide temperature range.

Rebound resiliency ("stretch-back"): Fabrics have excellent rebound resiliency due to the flexible elastic coating which forms on the fiber surface.

Chemical stability: They are chemically inactive, so they do not cause corrosion, swelling, or deformation of molds or molded items.

Can be used on complex molds: Silicone mold-release agents have low surface tension, so they provide good wetting of intricately shaped molds. This means that even complex molded items release easily from the mold

Latex release agent Emulsion type releasing agent is silicone emulsion (O / W type) which emulsified silicone oil with various emulsifiers, and especially, it is excellent in the dilution stability. Since it can be diluted with water, it is excellent in work ability and economy, and there are few restrictions on safety and health. It can be used for wide range of applications such as rubber, plastic mold release, and stout out.