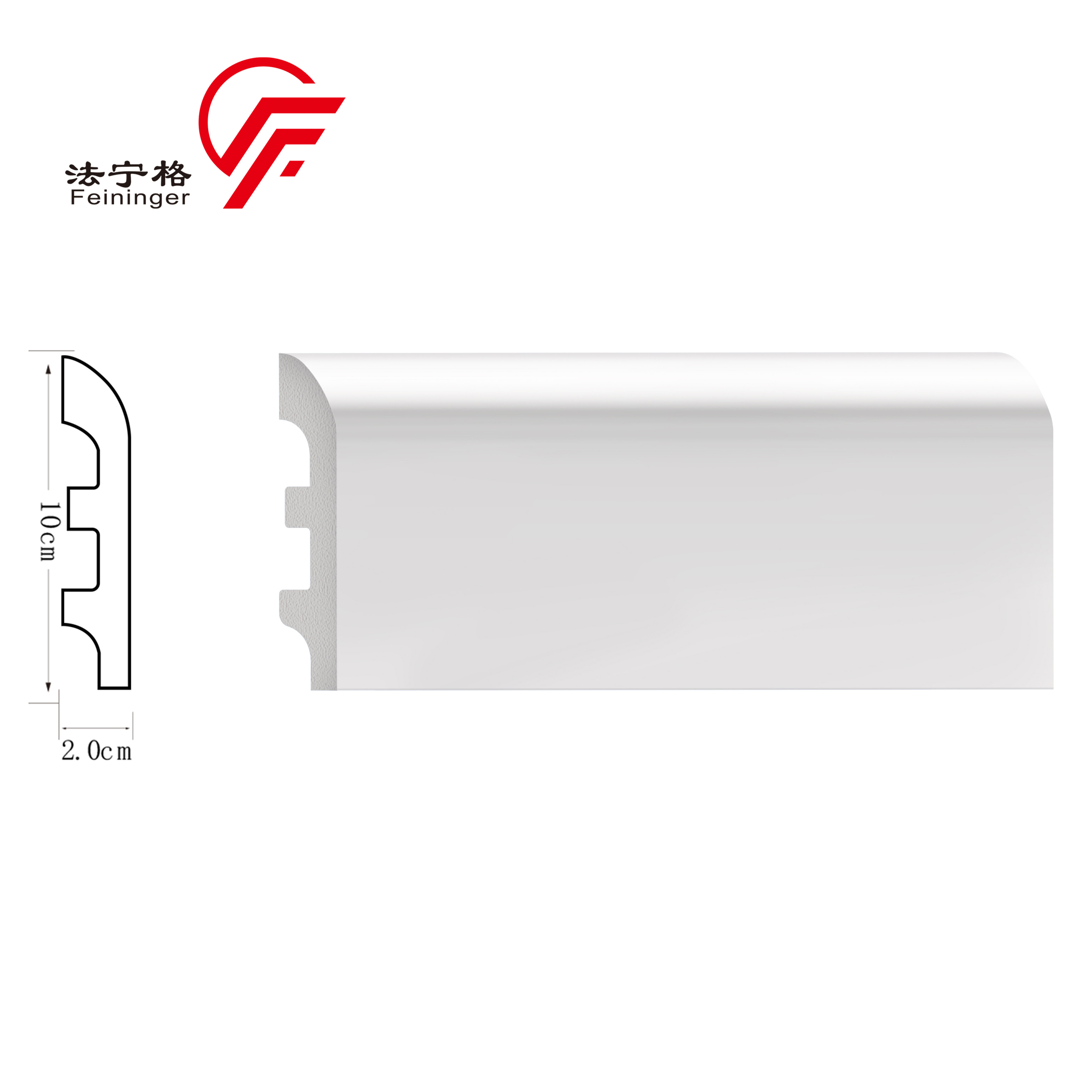

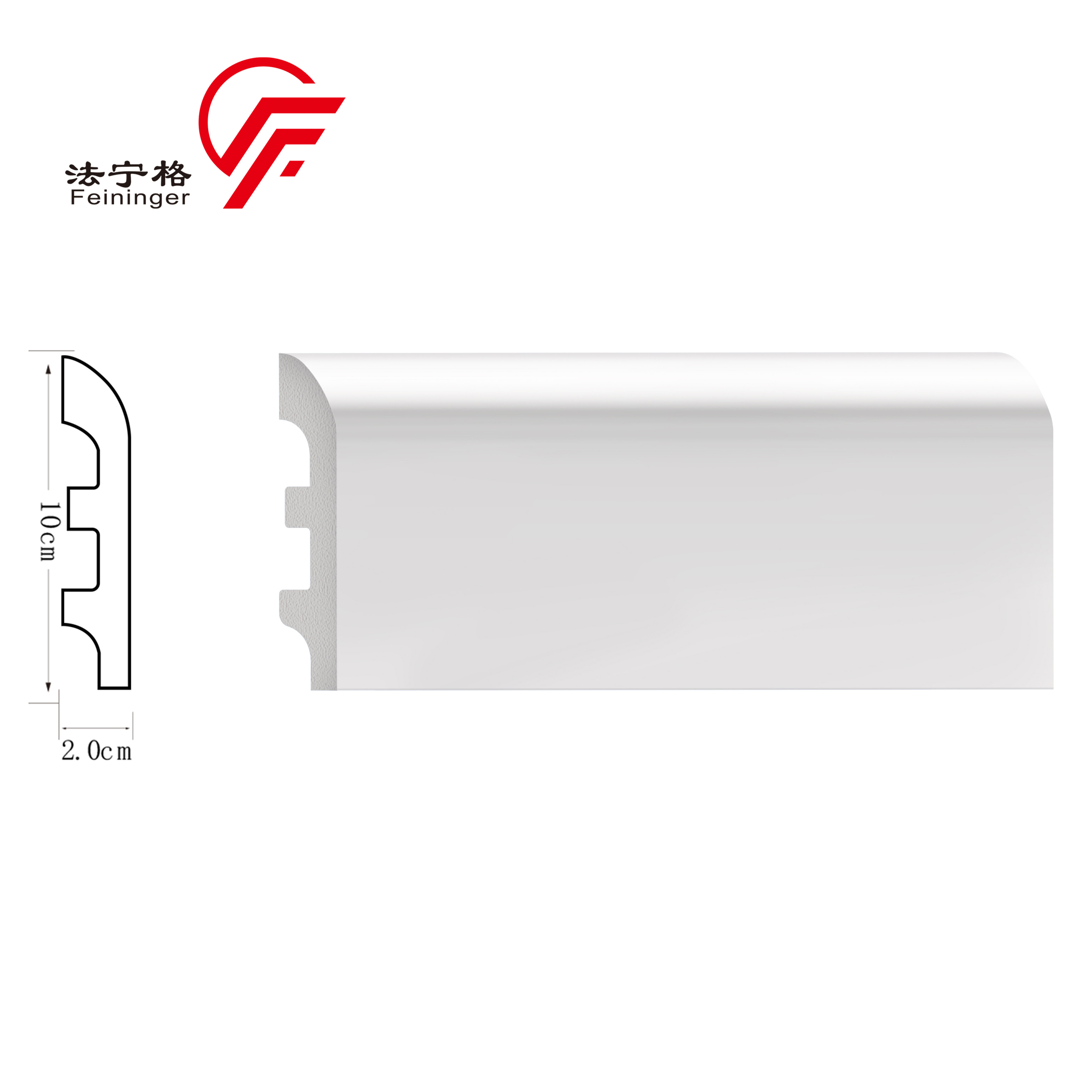

1. PS Baseboard by Feininger is a water-proof molding that can be installed in both dry and potentially wet areas of the house such us laundries and bathrooms. Because PS material is resistant to water damage and much more durable than a regular wood or MDF baseboard.

2. PS skirting board is 100% recyclable product.

3. PS baseboards have a simplified conservation, as it is easy to clean. Just using a wet cloth through out the moulding is enough to keep the skirting beautiful.

4. High density polystyrene baseboard has an excellent cost-benefit ratio. As it is resistant and does not suffer from certain characteristics that usually affect wood, it has a long useful life and durability. So, we won’t have to change it anytime soon.

- Product Details

- {{item.text}}

Quick Details

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Feininger

-

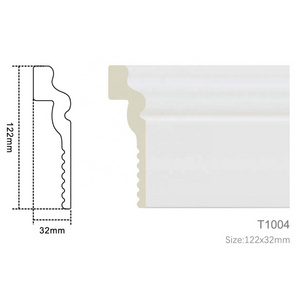

Model Number:

-

LGS-2105S

-

Material:

-

Polystyrene

-

Color:

-

White Grey Brown

-

Usage:

-

Wall Base

-

Length:

-

8mm 6mm 10mm

-

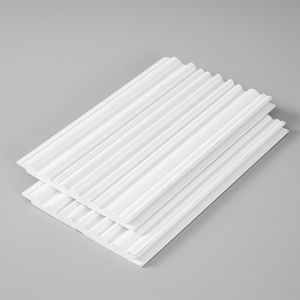

Package:

-

Cartoon

-

CERTIFICATE:

-

ISO9001 ISO45001 ISO14001

-

Advantage:

-

Waterproof, 100% Eco-friendly, Rigid

-

Style:

-

Mordern

-

Density:

-

200 Kg/m3-300Kg/m3

-

OEM:

-

Acceptable

Quick Details

-

After-sale Service:

-

Onsite Installation, Free spare parts

-

Project Solution Capability:

-

3D model design

-

Application:

-

Home Hotel

-

Design Style:

-

Modern

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Feininger

-

Model Number:

-

LGS-2105S

-

Material:

-

Polystyrene

-

Color:

-

White Grey Brown

-

Usage:

-

Wall Base

-

Length:

-

8mm 6mm 10mm

-

Package:

-

Cartoon

-

CERTIFICATE:

-

ISO9001 ISO45001 ISO14001

-

Advantage:

-

Waterproof, 100% Eco-friendly, Rigid

-

Style:

-

Mordern

-

Density:

-

200 Kg/m3-300Kg/m3

-

OEM:

-

Acceptable

Products Description

PS Skirting boards are simple to install and are available in a multitude of finishes that allow you to paint them as you like. This a low maintenance and inexpensive ornamental function, if your skirting is damaged worry not as it is easy to replace.

|

Item

|

High Density Polystyrene Skirting Board

|

|

Color

|

White or Customized color

|

|

Width

|

6cm 8cm 10cm

|

|

Usage

|

Indoor Decoration: Home, Hotel, Office

|

|

OEM

|

Acceptable

|

|

Origin

|

Jiangsu, China

|

Our Products

Our Advantages

Successful Case

We recommend you avoid using wooden skirting if you want to minimise maintenance tasks around the home. You will find PS skirting board easier to keep clean. Cracked, chipped and marked traditional skirting can really let the look of a room down. If you want to retain a fresh finish, Feininger high density PS skirting board is the perfect solution.

Our Production Line

1. Add the raw materials to be processed in a certain proportion and pour it into the mixer.

2. After regular mixing and homogenizing, they are transported to a quantitative feeder bin by a feeder.

3. The feeder is evenly fed to the outlet of the main extruder according to the addition amount set by the customer.

4. The raw material is conveyed to the heat exchanger by the high-temperature screw of the main engine, and the heat is

homogenized.

5. Then the material is conveyed to the extrusion equipment after the die, in which carbon dioxide foaming agent is injected quantitatively.

6. The material model of high-temperature products made by mould is formed after cooling into a two-stage shaping jacket.

7. Then the material is cooled through a water channel.

8. The products are drawn to a tractor and cut with a fixed length.

9. Finally, it is formed into a qualified product and packaged and sold.

2. After regular mixing and homogenizing, they are transported to a quantitative feeder bin by a feeder.

3. The feeder is evenly fed to the outlet of the main extruder according to the addition amount set by the customer.

4. The raw material is conveyed to the heat exchanger by the high-temperature screw of the main engine, and the heat is

homogenized.

5. Then the material is conveyed to the extrusion equipment after the die, in which carbon dioxide foaming agent is injected quantitatively.

6. The material model of high-temperature products made by mould is formed after cooling into a two-stage shaping jacket.

7. Then the material is cooled through a water channel.

8. The products are drawn to a tractor and cut with a fixed length.

9. Finally, it is formed into a qualified product and packaged and sold.

Certifications

Exhibition

Factory Strength

Hot Searches