- Product Details

- {{item.text}}

Quick Details

-

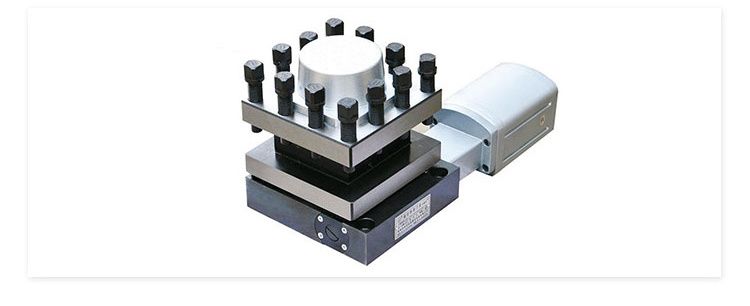

Center height of turret:

-

70/81/110/112/120/133/145/155/160

-

Number of tool-path:

-

4

-

use on which machine tool:

-

flat bed

-

rotary 90 degree need time:

-

2.0 sec

-

Built-in cooling:

-

yes

-

Max tangential torque:

-

500

-

Repeatability accuracy:

-

+/-2

-

Motor power:

-

120 W

-

wooden box size:

-

400x300x300

-

Type:

-

Turret

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Weight (KG):

-

7

-

Standard:

-

Other

-

Center height of turret:

-

70/81/110/112/120/133/145/155/160

-

Number of tool-path:

-

4

-

use on which machine tool:

-

flat bed

-

rotary 90 degree need time:

-

2.0 sec

-

Built-in cooling:

-

yes

-

Max tangential torque:

-

500

-

Repeatability accuracy:

-

+/-2

-

Motor power:

-

120 W

-

wooden box size:

-

400x300x300

-

Type:

-

Turret

Main performance, technical data and overall dimensions

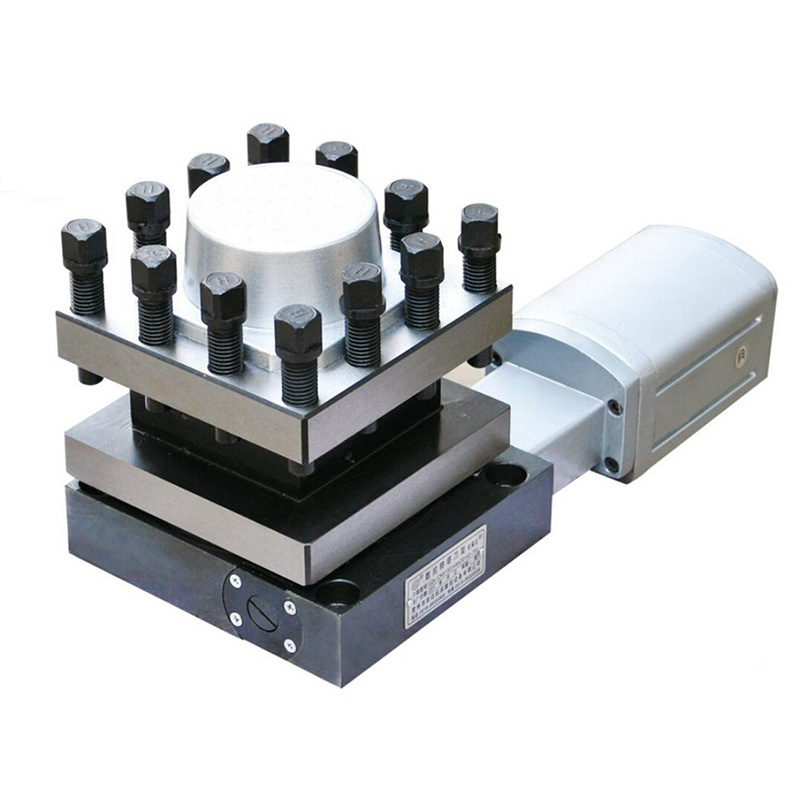

LD4 series CNC vertical rotary turret is a new generatio product designed, developed and produced by our company, is the key function unit of NC lathe. When turret rotating, the u pper housing is rised, It features high accuracy of position , with Hall unit sending signals and good performance of waterproof . Various kinds of NC lathe equipped with the turrets can be operated to facing ,turning, boring, threading and grooving in one fixing.

|

Parts List of LD4 Series Turret

|

|

|

|

|||

|

NO.

|

Name of parts

|

Material

|

Remark

|

|||

|

1

|

Motor

|

|

380V Three-phase

|

|||

|

2

|

Coupling(right)

|

45

|

|

|||

|

3

|

Coupling(left)

|

45

|

|

|||

|

4

|

Connecting seat

|

45

|

|

|||

|

5

|

Bearing

|

|

Deep groove ball bearing

|

|||

|

6

|

Worm

|

45

|

|

|||

|

7

|

Adjustable pad

|

45

|

|

|||

|

8

|

Bearing

|

|

Deep groove ball bearing

|

|||

|

9

|

Cover of bearing

|

45

|

|

|||

|

10

|

Plug

|

45

|

|

|||

|

11

|

Main shaft

|

45

|

|

|||

|

12

|

Turret base

|

45

|

|

|||

|

Please inquire for more details

|

|

|

|

|||

SELECTION AND USE OF NC TURRET

1.Confirm various parameters when choosing modes of turret. Choose the number of stations according to quantity of part procedure and comoicacy

2. Choose tool specifications according to model of machine tool and cutting force, choose front-type or rese-type tool turret according to the cutting directions of the machine tool.

3. After the mounting of boring cutter seat of horizontal turret self-bore the inner hole according to the size of boring bar and make a corresponding mark. The tool should be fixed in the former position in the later mounting.

4.The distance tool reaching out of upper housing distance is usually not more than 2/3

upper housing size. Please note when placing an order if more than the limit.

5. Touch by hand or other things is forbidden when turret is running to avoid injury or damage.

6.If customers have any special requirements or changes in parameters, please offer some data and contact with our company.

7.In order to improve our products.some parameters will change accordingly. We make an apology to you for amending this catalogue without further notice.

7.In order to improve our products.some parameters will change accordingly. We make an apology to you for amending this catalogue without further notice.

|

Trouble shooting

|

|

|

||

|

Phenomenon of trouble

|

Causes of trouble

|

How to do

|

||

|

1.If switch on power supply, motor stopping and turret does not work

|

(1)The three phases of power supply are not correct

(2) Low voltage of power supply (3)Power phase lack

|

(1) Cut off Power supply, adjust phases sequence of power supply

(2)Check if the voltage of power supply is normal before use

|

||

|

2.Turret rotating continuously or does not stop at a special position

|

1.Trouble occurs in power supply of s ignalling disk

2.Trouble occurs in the signal wire of a special position

3.One of Hall unit is short circuit or destroyed

4. The magnetic poles of magnetic steel is revers, or magnets is lower;

|

1.Check if the power supply voltage of s ignalling disk is normal; 2.Check if the wiring of s ignalling disk and machine tool is short circuit or opening

3. To replace hall element or s ignalling disk with a new one 4. Adjusting the direction of magnetic steel or replace with a new one 5. Adjusting the position between magnetic steel and Hall element |

||

|

3.Turret is not clamped tight enough

|

1. The delay time of reverse rotating is not enough 2.The wiring of contactor for motor positive or reversing rotating is not

undesirable 3. Shut off the contactor for motor reversal rotating with the locking signal of turret 4.Main shaft is bending after colliding of the turret. |

1.To reset the locking time of reverse rotating;

2.Check if the related wiring of machine tools is appropriate; check if the related control program of machine tools is correct; 3.Don`t control the reversal rotating contactor of motor with the locking signal of turret 4. Disassemble the turret and check the main shaf |

||

|

4.Turret rotating is not stoping in special position or there is too much shock

|

1.In the direction of circle ,the position of magnetic steel too far from Hall unit in front or in rear 2.Within the program of

machine, the time of delay is too long between stopping of motor positive rotating and starting of motor reverse rotating |

1.Adjust the relative location of magnetic steel and Hall unit in the direction of circle 2.revise the program of machine, delete

the delay between stopping of motor positive rotating and starting of reverse rotating |

||

|

5. The processing surface appear corrugated

|

1.Turret is not fully locking; 2. Cutter arboris is not rigid enough, or tool fixed is less robust.

|

1. Extend the locking time of turret properly. 2. Using rigid cutter arbor and fixing them firmly

|

||

Our company adheres to international quality standards strictly and serves the market with qualified products to improve customer satisfaction.

The forthcoming overseas warehouse direct-selling aims at meeting the requirements of small quantity and fast delivery for customers abroad.

Make the world better is the vision of DLKCNC's employees. We hope to create a bright future together with you.

Each of our products has passed authoritative professional certification

We assure you that all products are worth the money.

We assure you that all our premium services will give you peace of mind.

Hot Searches