- Product Details

- {{item.text}}

Quick Details

-

Injection Rate (g/s):

-

80 g/s

-

Injection Weight (g):

-

150 g

-

Screw diameter (mm):

-

38 mm

-

Distance between Tie Bars:

-

H360*V244mm

-

Weight (KG):

-

1550

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

200 mm

-

Model Number:

-

FZY-100

-

Brand Name:

-

Rich Union

-

Power (kW):

-

7.5 kW

-

Clamping Force (kN):

-

800 kN

-

Certification:

-

CE ISO9001 LVD

-

Screw Diameter:

-

38mm

-

Injection pressure:

-

130MPa

-

Platen Size:

-

525*405mm

-

Mold Thickness:

-

100-330mm

-

Machine Color:

-

Customized

-

Space Between Tie Bars(H*V):

-

H360*V244mm

-

Machine Weight:

-

1.55T

-

Injection Rate:

-

80g/s

-

Injection Weight:

-

150g

-

Power(W):

-

7.5KW

Quick Details

-

Ejector Stroke(mm):

-

140 mm

-

Ejector Force(kN):

-

140 kN

-

Theoretical Shot Volume(cm³):

-

140 cm³

-

Injection Rate (g/s):

-

80 g/s

-

Injection Weight (g):

-

150 g

-

Screw diameter (mm):

-

38 mm

-

Distance between Tie Bars:

-

H360*V244mm

-

Weight (KG):

-

1550

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

200 mm

-

Model Number:

-

FZY-100

-

Brand Name:

-

Rich Union

-

Power (kW):

-

7.5 kW

-

Clamping Force (kN):

-

800 kN

-

Certification:

-

CE ISO9001 LVD

-

Screw Diameter:

-

38mm

-

Injection pressure:

-

130MPa

-

Platen Size:

-

525*405mm

-

Mold Thickness:

-

100-330mm

-

Machine Color:

-

Customized

-

Space Between Tie Bars(H*V):

-

H360*V244mm

-

Machine Weight:

-

1.55T

-

Injection Rate:

-

80g/s

-

Injection Weight:

-

150g

-

Power(W):

-

7.5KW

Products Description

|

Item number

|

FZY-100

|

|

Screw Diameter(mm)

|

38

|

|

Theoretical Injection Volume(cm

3

)

|

130

|

|

(PS)Injection Weight(g)

|

120

|

|

Max.Injection Pressure (Kgf/cm

2

)

|

140

|

|

Injection Rate (cm

3

)

|

80

|

|

Screw speed Rotation (r/min)

|

0-180

|

|

Clamping Force (kn(tf))

|

800

|

|

Clamping Stroke (mm)

|

250

|

|

(h*v)Distance Between Tie Bars (mm)

|

360*244

|

|

(l*w)Max. Mould Size (mm)

|

525*405

|

|

Min.Mold Thickness (mm)

|

100-330

|

|

System Pressure (MPA.Kgf/cm

2

)

|

16

|

|

Eletrice Power [KW(HP)]

|

5.5

|

|

Heating power [KW(HP)]

|

4.8

|

|

Machine Diamensions (l*w*) (m)

|

1.6*0.9

|

|

Machine high (m)

|

2.6

|

|

Machine Weight (T)

|

1.1

|

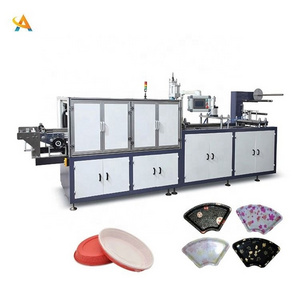

Application

Details

Positioning swivel design

Make the mold installation more convenient and the distant can more accurately.

The crank arm design

Following the machinery rules,let the mode looking more powerful,and extend the life of the machine.

Infrared Sensor

Human body infrared induction installation device can let you more safe when you use it.

Solid press casting mould

Solid press casting mould,withstand voltage,wear-resistant wearproof,and durable.It is high performance cost.

How to choose a right machine

|

Model(FZY-)

|

80

|

100

|

125A

|

160

|

200

|

300

|

400

|

500

|

||||||

|

Screw Diameter(mm)

|

35

|

38

|

40

|

42

|

45

|

50

|

55

|

60

|

||||||

|

Theoretical Injection Volume(cm

3

)

|

130

|

130

|

130

|

130

|

140

|

140

|

140

|

140

|

||||||

|

(PS)Injection Weight(g)

|

100

|

120

|

135

|

170

|

269

|

360

|

420

|

550

|

||||||

|

Max.Injection Pressure(

kgf/cm

2

)

|

130

|

140

|

140

|

180

|

280

|

280

|

280

|

580

|

||||||

|

Injection Rate(cm

3

)

|

70

|

80

|

90

|

95

|

155

|

155

|

155

|

155

|

||||||

|

Screw speed Rotation(r/min)

|

0-180

|

0-180

|

0-200

|

0-200

|

0-220

|

0-240

|

0-240

|

0-260

|

||||||

|

Clamping Force(kn(tf))

|

700

|

800

|

800

|

800

|

1000

|

1200

|

1200

|

1300

|

||||||

|

Clamping Stroke

|

250

|

250

|

250

|

320

|

320

|

320

|

320

|

320

|

||||||

|

(h*v)Distance Between Tie Bars(mm)

|

360*244

|

|

360*244

|

390*285

|

405*296

|

450*325

|

450*325

|

517*339

|

||||||

|

(l*w)Max. Mould Size(mm)

|

525*405

|

|

525*405

|

530*430

|

565*450

|

625*505

|

625*505

|

710*520

|

||||||

|

Min.Mold Thickness(mm)

|

100-320

|

100-330

|

100-330

|

100-330

|

100-350

|

100-350

|

100-350

|

100-350

|

||||||

|

System Pressure(

mpa.kgf/cm

2)

|

16

|

|

16

|

16

|

18

|

18

|

18

|

20

|

||||||

|

Eletrice Power(

kw(hp))

|

5.5

|

5.5

|

7.5

|

7.5

|

11

|

11

|

11

|

13

|

||||||

|

Heating power

(kw(hp))

|

4.8

|

4.8

|

|

|

5

|

6

|

6

|

7

|

||||||

|

Machine Diamensions (l*w*)(

m)

|

1.6*0.9

|

1.3*0.9

|

1.6*0.9

|

1.65*0.9

|

1.4*1

|

1.68*1.2

|

1.68*1.2

|

1.68*1.2

|

||||||

|

Machine high(

m)

|

2.6

|

|

2.6

|

2.6

|

28

|

3

|

3

|

3

|

||||||

|

TMachine Weight(

T)

|

1

|

1.1

|

1.1

|

1.2

|

1.5

|

1.6

|

1.6

|

2

|

||||||

Double Crane Arm Series

How to become a full-auto production line

Technical Support

Pre‐sale service

.

Visiting our factory

If you think you can’t know about the injection molding machine comprehensive, worried about you don’t know how to use,you can come to our factory. We can help you to know about our products including how to use fix and keep it well.We can pick you up when you arrive and offer food but not including accommodation.

Good recommendation

If you are a layman that you don’t know how to choose the most suitable inject machine and let it reach the maximize profits.We can calculate a data for you depend on your information and choose the best one for you.Save you money and time.

Learn online

If you are not convenient come to our factory,we can give you some information and operation vedio, machine’s data for you.We will help you to operate the machine online.

Aft

er‐sale service

.

Hot Searches