- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product

-

Usage:

-

Automatic Control Operation

-

Name:

-

Aluminum Condenser Tube Continuous Extrusion

-

Frequency:

-

50-120khz

-

Production Speed:

-

15/min

-

Capacity:

-

200-300kg/h

-

Final product:

-

Aluminum Profile

-

Function:

-

embossing

-

Product name:

-

plate Embossing Machine

-

Keyword:

-

embossing

-

Color:

-

blue

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Zhontuo

-

Weight (KG):

-

3000

-

Marketing Type:

-

New Product

-

Usage:

-

Automatic Control Operation

-

Name:

-

Aluminum Condenser Tube Continuous Extrusion

-

Frequency:

-

50-120khz

-

Production Speed:

-

15/min

-

Capacity:

-

200-300kg/h

-

Final product:

-

Aluminum Profile

-

Function:

-

embossing

-

Product name:

-

plate Embossing Machine

-

Keyword:

-

embossing

-

Color:

-

blue

Product Description

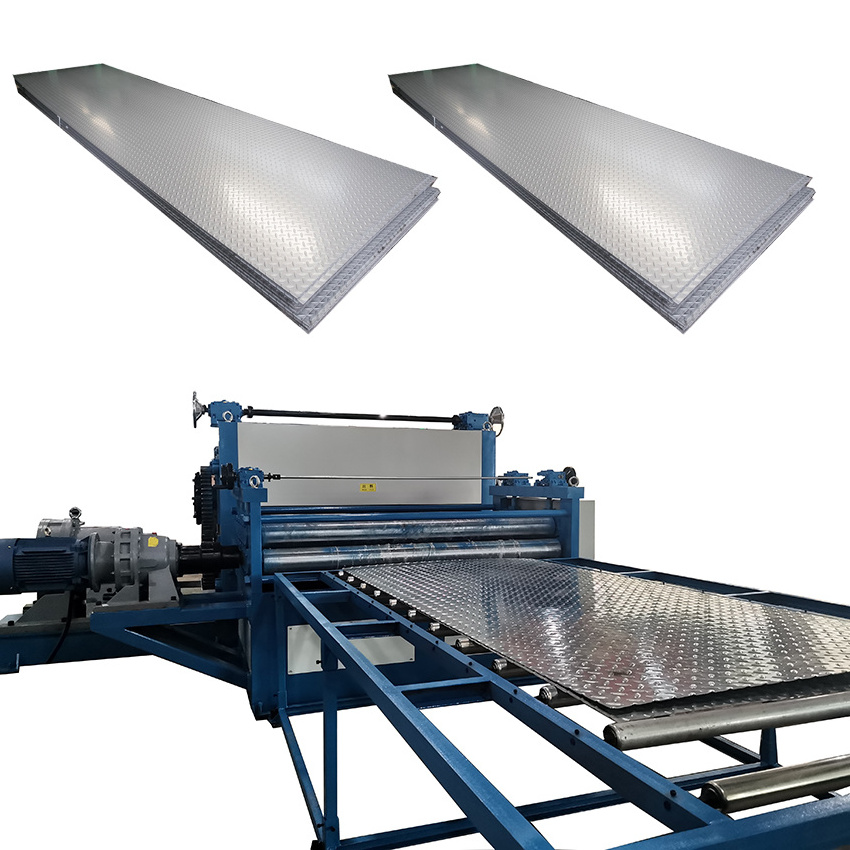

Metal Embossing Machine

A metal sheet embossing machine line is always required for the production of raised or sunken designs or relief in sheet metal continuously from unrolling or uncoiling, embossing and recoiling.

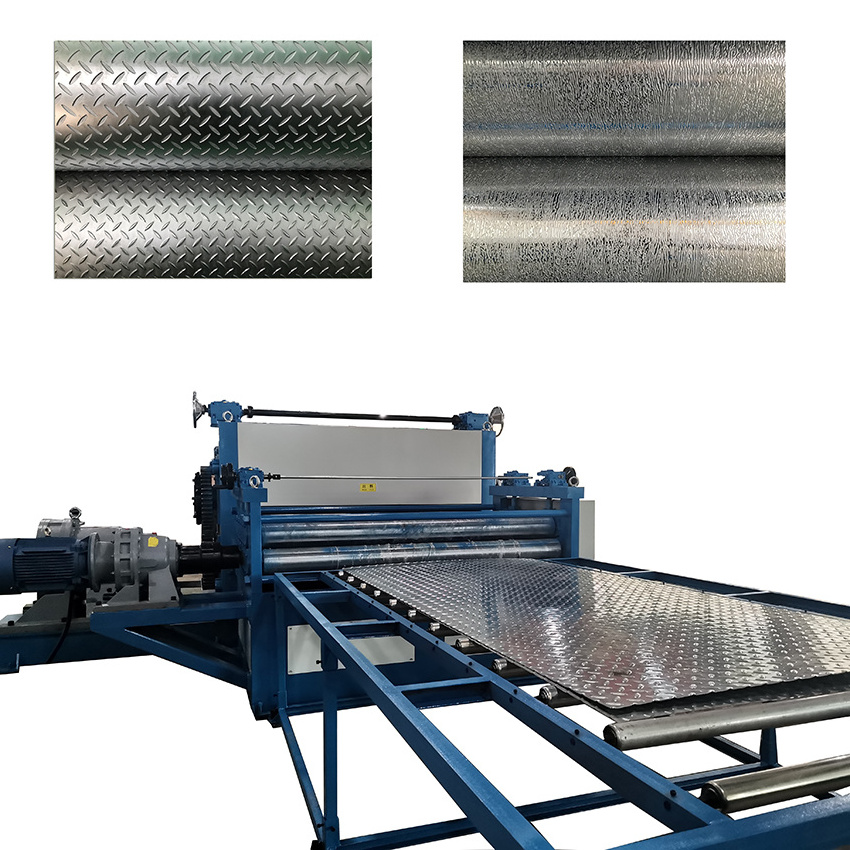

Products Display

Introduction

Metal sheet embossing

is a stamping process to produce various designed patterns in sheet metal by passing the sheet in roll or a strip of metal between rolls of the desired patterns. Metal sheet or steel coil is fed into the male and female roller dies on a sheet metal embosser so that a pattern or a design will be engraved on the metal sheet.

Parts to introduce

Other design

Different designed patterns can be embossed by changing the designing of roller dies on the embossing machine. A metal sheet embosser produce the patterns on each every fed piece of metal sheets, while a metal sheet embossing machine line can produce designed patterns continuously on uncoiled or unrolled metal sheet and after the embossing process, the embossed metal sheet will be re-rolled or re-coiled for other purposes.

Main Parameter

|

Embossing Machine

|

|

|

|

Coil Thickness

|

3mm maximum

|

|

|

Coil width

|

1500mm maximum

|

|

|

Working Speed

|

15m/min

|

|

|

Main Power

|

11 Kw

|

|

Product Advantages

Brief Description of Metal Sheet Embossing Machine Line:

A metal sheet embossing machine line designed by Zhongtuo is technically capable to produce customized patterns on metal sheets with thickness up to 3mm thickness and width up to 1500mm. The metal materials a metal sheet embossing machine line usually handles with are galvanized steel, pre-painted steel, aluminum and stainless steel etc.

Our Advantages

In all sheet metal embosser we design and build, the upper roll blocks are stationary, while the bottom roll blocks are adjustable up and down for the feeding of different thickness materials. Depends on different purposes, there will be two options for customers to produce various patterns on metal sheets: an individual Sheet Metal Embosser and a continuous Metal Sheet Embossing Machine Line.

An individual sheet metal embossing machine consists of two main roller dies, a main motor, embosser base structure and control system, while a continuous metal sheet embossing machine line consists of a decoiler (most of time Hydraulic Decoiler), a sheet metal embosser, a recoiler (the same as decoiler), and control system.

Hot Searches