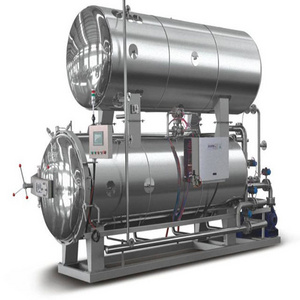

adopted high speed spraying, so that the temperature in the pot is kept stable and the sterilization effect is improved.

2. Direct heating and indirect cooling, and prevent the second pollution. Sterilizing and cooling processes use the same water.

Circulating water is directly heated by steam diffusion tube in the heating process. Under 0.5MP apressure, it only takes 6-12 min

to rise the temperature from 20 DEG to 121 DEG. Continuous cooling by heating exchanger is isolated from the products, preventing

the second pollution in the cooling effectively

3.Full-automatic control system

a.Simens touch screen

b.No-paper recorder

c.Imported automatic valves

a.Simens touch screen

b.No-paper recorder

c.Imported automatic valves