- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Honor Machine

-

Dimension(L*W*H):

-

customizable

-

Weight:

-

4500 KG

-

Product name:

-

Gallon Filling Machine

-

Capacity:

-

60-1200bph

-

Function:

-

Filling Labeling

-

Suitable bottle:

-

PET / PC bottle

-

Bottle size:

-

3-5gallon

-

Machine material:

-

SUS304/316

-

Filling liquid:

-

Mineral / Pure Water

-

Filling system:

-

Graviity filling water valve

-

Control system:

-

PLC (SIEMENS)

-

After-sales Service Provided:

-

2 years

Quick Details

-

Machinery Capacity:

-

12000BPH, 400BPH, 500BPH, 1000BPH, 200BPH, 300BPH, 600BPH, 900BPH, 60-120BPH

-

Packaging Material:

-

Plastic, Metal, Wood

-

Filling Material:

-

Beer, Milk, Water, Oil, Juice

-

Filling Accuracy:

-

±0.1%

-

Voltage:

-

Customized

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Honor Machine

-

Dimension(L*W*H):

-

customizable

-

Weight:

-

4500 KG

-

Product name:

-

Gallon Filling Machine

-

Capacity:

-

60-1200bph

-

Function:

-

Filling Labeling

-

Suitable bottle:

-

PET / PC bottle

-

Bottle size:

-

3-5gallon

-

Machine material:

-

SUS304/316

-

Filling liquid:

-

Mineral / Pure Water

-

Filling system:

-

Graviity filling water valve

-

Control system:

-

PLC (SIEMENS)

-

After-sales Service Provided:

-

2 years

Full Automatic Bottled 19 20 L Mineral Drinking Water 5 Gallon Big Bottle Filling Capping Machine

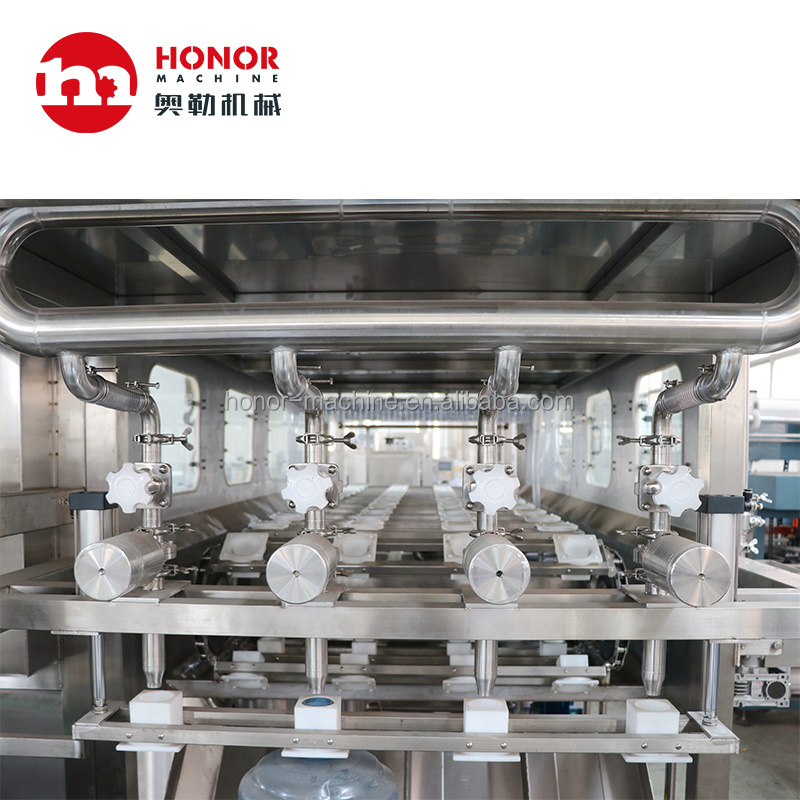

QGF 3-in-1 5Gallon Water Filling Machine

The production line is mainly used for 3-5 gallon barrel drinking water. It consists of three parts: washing(heating water---sterilized water---pure water), filling and sealing.

This production line can be automatically washed, disinfected, filled, capped, counted and output, with complete functions, novel design, high degree of automation, it is a set of machinery, electricity, gas in one of the drinking water barrel equipment.

| Model | QGF-120 | QGF-300 | QGF450 | QGF-600 | QGF-900 | QGF-1200 |

| Filling Head | 1 | 2 | 3 | 4 | 6 | 8 |

|

Volume(gallon) |

3-5gallon | 3-5gallon | 3-5gallon | 3-5gallon | 3-5gallon | 3-5gallon |

|

Capacity(barrels/h) |

60-120 | 120-300 | 300-450 | 450-600 | 600-900 | 900-1200 |

| Barrel size(mm) | 270*490 | 270*490 | 270*490 | 270*490 | 270*490 | 270*490 |

| Gas pressure(Mpa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 | 0.6 | 0.6 | 0.6 |

|

Gas consumption (m3/min) |

0.37 | 0.6 | 0.8 | 1 | 1.5 | 1.8 |

| Total power(KW) | 1.5 | 3.8 | 5.5 | 7.5 | 9.8 | 13.5 |

|

Weight(KG) |

680 | 1500 | 2100 | 3000 | 3500 | 4500 |

Honor Machine

provides the wide range of liquid filling capabilities and industry experience while delivering the lower cost of ownership for our customers.

We are not only a filling equipment manufacturer, but also design and build factories, equipment layout, circuit layout and equipment operation schemes. Our equipment is designed carefully, easy to use and easy to manage. Whether you need a machine or a complete filling and packaging system, we have rich experience to ensure the successful completion of your project.

Since 2008, Honor Machine has been one of the leading suppliers of packaging technology. Located in the beautiful city of Zhangjiagang, Jiangsu Province, a new port city famous for professional industrial city. We are committed to:

1)Automatic industry water treatment system(Reverse Osmosis, Ultrafiltration)

2)All kinds of beverage filling and packaging production lines (water, juice, carbonated drink, all kinds of liquors)

3)3-10L beverages filling and packaging production line

4)3-5 gallon beverages filling and packaging production line

5)Alcohol/beer filling and packaging production line

6)All kinds of Edible Oil and Oil Filling and Packaging Production Lines

7)All kinds of sauce filling and packaging production lines (honey, jam)

8)Zip-top can filling and packaging production line

9)Automatic/Semi automatic bottle blowing system

10)Automatic injection blowing/ Extrusion blowing machine

Your Success Is Our Mission!

Q1.How to tell us your enquiry?

A1:You can contact us by email, phone call, Instant Messenger (Trademanager, WhatsApp, Skype) and let us know your requirement.

Q2:Are you a factory or trading company?

A2:We are a factory, professional water treatment system manufacturer and bottled water filling & packing machinery with about 7 years experience. Factory covers an area of 5,000 square. There have been more than 50 countries use our products.

Q3.Where is your factory?

A3:Our factory is located in NO.198 Zhenbei Road Leyu Town,Zhangjiagang City,JiangSu Province,China, it is near to Shanghai or Wuxi (airplame and train both available). If you arrive at Shanghai or Wuxi, we can pick you up to visit our factory.

Q4.How about after-sale service?

A4:After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools.After the commissioning, we will package the equipment by standard export package for shipment.

Q5:How long is the warranty of your equipment and installation?

A5:2 years warranty after receipt check upon delivery.

We will send our professional engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back,accommodation and USD120 / day/person.

Q6:What is the features of our company?

A6: We provide turnkey project for customers, including sale and after-sale service; complete production line equipment supply; bottle design; layout programs provide; or provide auxiliary materials purchasing agent supplier information; equipment overseas installation and commissioning; operator training etc

Q7:How to guarantee your funds to be safe and delivery to be on time?

A7:Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.