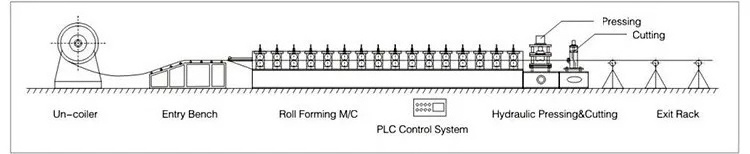

The coil inner diameter: φ450-550mm;

Max. outer coil diameter: φ1000mm-1250mm

The max capacity: 5T

Max. outer coil diameter: φ1000mm-1250mm

The max capacity: 5T