- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw depends on capacity

-

Dimension(L*W*H):

-

20-100M2 depends on capacity

-

Weight:

-

500 KG

-

Application Industries:

-

Beer Brewing Micro Brewery

-

Control method:

-

PLC Controller Cabinet

-

Product Name:

-

Stainless Steel Beer Brewing Equipment

-

Function:

-

Brewing Beer Brewing Equipment

-

Material:

-

SUS304/SUS316/red Copper

-

After-sales Service Provided:

-

Field installation, commissioning and training

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Tiantai

-

Voltage:

-

3phase/380v/50Hz

-

Power:

-

15-70Kw depends on capacity

-

Dimension(L*W*H):

-

20-100M2 depends on capacity

-

Weight:

-

500 KG

-

Application Industries:

-

Beer Brewing Micro Brewery

-

Control method:

-

PLC Controller Cabinet

-

Product Name:

-

Stainless Steel Beer Brewing Equipment

-

Function:

-

Brewing Beer Brewing Equipment

-

Material:

-

SUS304/SUS316/red Copper

-

After-sales Service Provided:

-

Field installation, commissioning and training

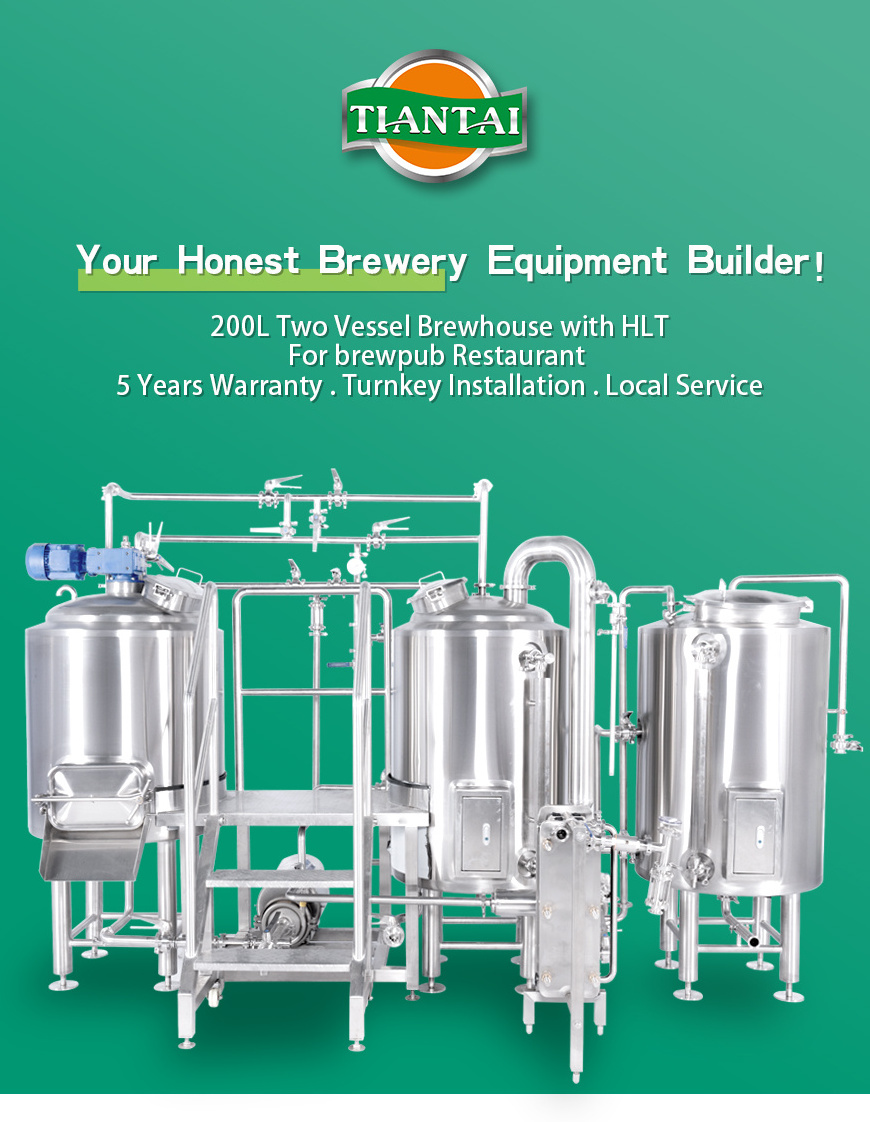

200L 1 barrel Jinan stainless steel electric heating three vessel small brewhouse brew system kettle

Part 1

General Description of 200L Brewhouse

------ Quality Design for Craft Brewing

1. Introduction

The 200L 2HL Jinan stainless steel electric heating three vessel brewhouse often used in microbreweries. The system contains 3 brewhouse vessels, a Mash tun,L auter tun , Kettle/W hirlpool tun . The mashing process is done in mash tun; the wort filtration process are completed by lauter tank; The boiling and whirlpool ing processes are completed by one kettle/whirlpool tank.

This system usually brews 1 batche a day. According to different fermentation cycles of brewed beer, 4 pcs 400L fe rmenters or 8 pcs 2 00L fermentors can usually be configured, and 3 pcs 400L fermenters and 6 pcs 2000L fermenters can also be configured to meet the needs of various beer types.

The system also needs to be equipped with a complete automatic or manual control system , malt milling system , CIP system , cooling system , steam heating system , air system , etc.

2. Our Advantage

> With ISO TUV SGS, the product meets the GB/

CE/PED/ASME

standard

>

Local service

in EUROPE, AUSTRALIA ETC

>

5 Years

Warranty for tanks

>

0 trade risk

verified by more than 1100 breweries

> 20 Years Manufacture and Management Experience

3. Features

>

Three

vessels with hot water

tank

,

200L

iter/b

atch

, first batch takes about 8 hours, and two batches of 1

2

hours are allowed

, it can do at most 2 batches per day

;

> All certificated

304

stainless steel, easy to clean; Copper cladding for special environments such as bars;

>

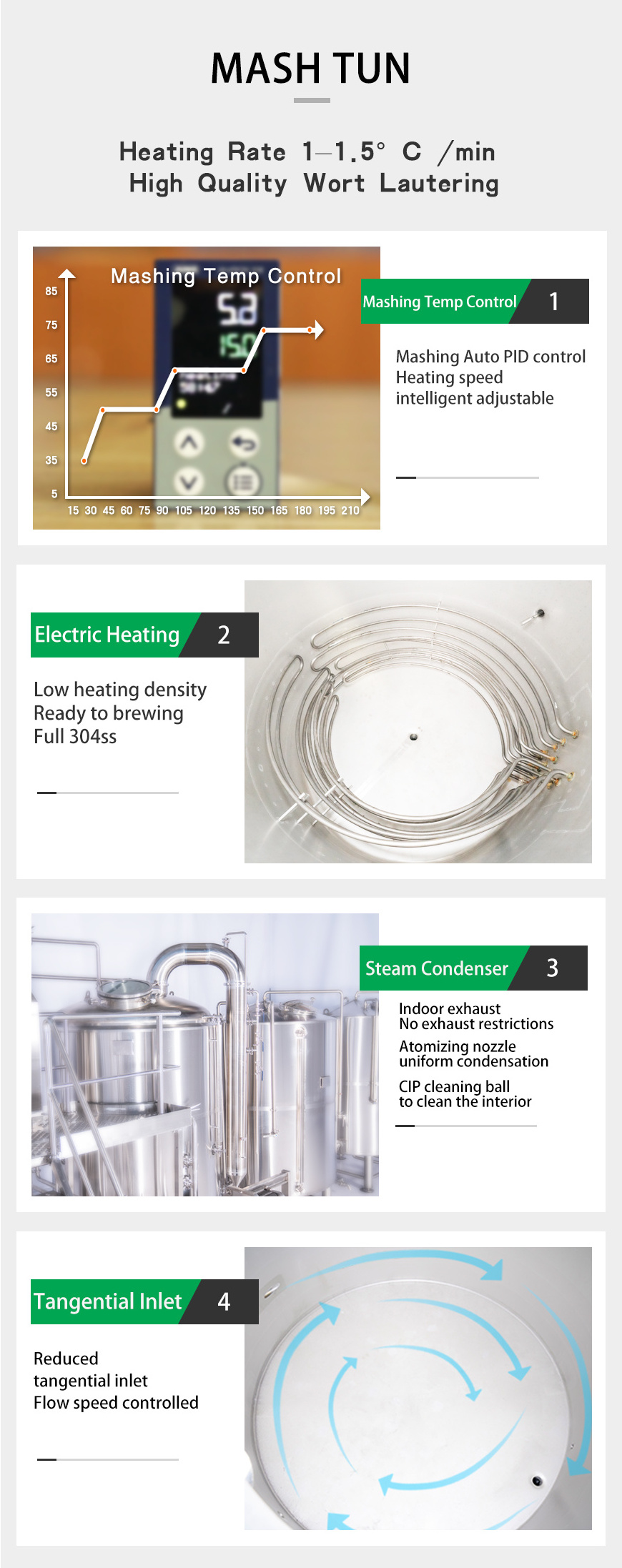

Electric

heat

ing

, high thermal efficiency, gentle for wort;

Steam

or direct fire heating

for option

;

> The

wort cooled

by tap water and -5 ºC ice water to cool in two stages, Single stage available;

> Mashing heating and fermentation cooling

automatically controlled

, and manual control switched at any time;

> Manual valve control, humanized operation, low equipment investment cost, high cost performance; PLC automatic control for upgrade;

4. Parameters

|

Design Basis

Ingredients: Malt Mashing: Infusion & Decoction OG: 12 Plato Boiling Strength: 8%-10% |

Energy Consumption

Heating: Electricity Electricity : 3P/380/50Hz Power: about 20 KW Water: Hot water recovery |

|

Dimension

Mash Tun: Φ 7 60mm Lauter Tun: Φ 7 60mm Kettle /Whirlpool Tun: Φ 7 60mm Floor Space:about 10 00* 30 00mm |

Controlling

Control Panel: Digital Button Type Brewing Valve: Manual CIP Valve:Manually Temperature:P ID Auto Control |

|

2HL Mash Tun |

1set |

|

2HL Lauter Tun |

1set |

|

2HL Kettl e/Whirlpool Tun |

1set |

|

2 HL Hot Water Tank |

1set |

|

Non-slip Work Plateform |

1set |

|

Sanitary Centrifugal Pump [LYSF] |

3 sets |

|

Sanitary Piping |

1set |

|

Valves and Fittings |

1set |

|

Manual Water Mixing Station |

1set |

|

Manual Wort Cooling Station |

1set |

|

Pipeline Instrument Sensor |

1 unit |

|

25L Glass Wort Grant |

1set |

|

Heat Exchanger [304SS NANHUA] |

1set |

|

Pipe Filter |

1set |

|

Wort Aeration Station |

1set |

|

1 0L Yeast Feeder |

1set |