- Product Details

- {{item.text}}

Quick Details

-

Size:

-

optional, 80mm-500mm

-

Warranty:

-

NONE

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

bigstars

-

Model Number:

-

1a1

-

Viscosity:

-

standard

-

Abrasive:

-

Diamond&CBN

-

Service:

-

OEM

-

Usage:

-

Surface grinding ,Internal grinding

-

Viscostiy:

-

High

-

MOQ:

-

5 Pieces

-

Certification:

-

Reach

Quick Details

-

Application:

-

Aluminum, Deburring, Ferrous Metals

-

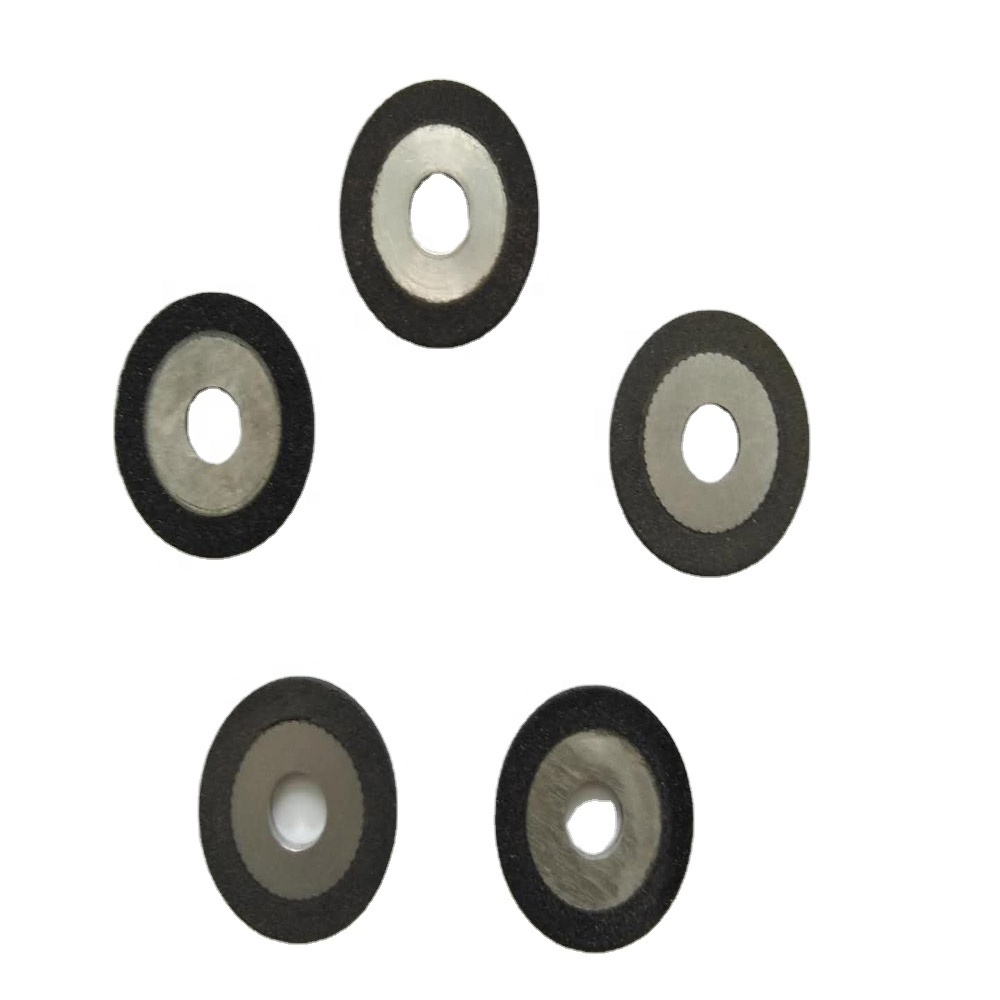

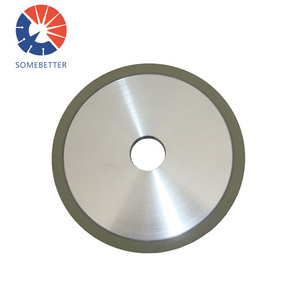

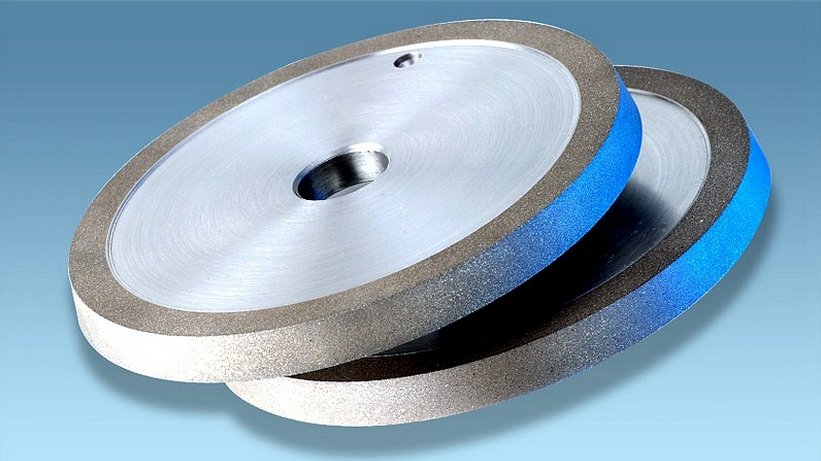

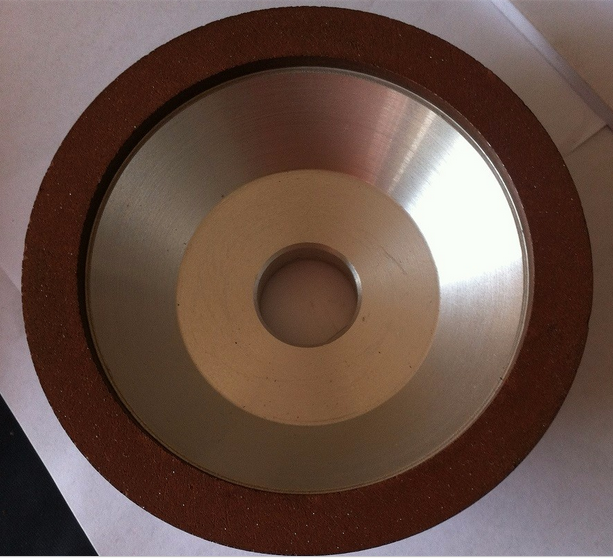

Shape:

-

Flat-Shaped

-

Hardness:

-

standard

-

Size:

-

optional, 80mm-500mm

-

Warranty:

-

NONE

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

bigstars

-

Model Number:

-

1a1

-

Viscosity:

-

standard

-

Abrasive:

-

Diamond&CBN

-

Service:

-

OEM

-

Usage:

-

Surface grinding ,Internal grinding

-

Viscostiy:

-

High

-

MOQ:

-

5 Pieces

-

Certification:

-

Reach

We will provide you with whatever specification grinding wheel you require. At Bigstars we only use the best, which produces the highest quality product. We will never compromise on the quality of the raw materials that go into our wheels.

At Bigstars everything will be built as our customers’ specifications.Different criteria or request and different your operator or stresses, its reason cases the different wheels you may really need from other wheels. It means that there is no perfect grinding wheel for everyone, and there is no magic formula for making wheels, but what we can do is to provide any wheel in whatever formula you require,and our experts will be on hand to discuss your requirements.

All of our Superabrasive wheels are produced within a certified ISO9001 quality environment which ensures a consistent product, the same one each time.

Technology creates high-quality goods. Profession is creditworthy.

Application and Performance

Hardness of abrasive and superabrasive

Materials to be ground

Characteristics of different bond

Indication of grit size

| Mesh Size | Averrage Diameter(µm) | FEPA | U.S.A |

| 50 | 297 | D301 | 50/60 |

| 60 | 250 | D252 | 60/85 |

| 80 | 177 | D181 | 85/100 |

| 100 | 149 | D151 | 100/120 |

| 120 | 125 | D126 | 120/140 |

| 140 | 105 | D107 | 140/170 |

| 170 | 88 | D91 | 170/200 |

| 200 | 74 | D76 | 200/230 |

| 230 | 62 | D64 | 230/270 |

| 270 | 53 | D54 | 270/325 |

| 325 | 44 | D46 | 325/400 |

| 400 | 37 | M40 | 36-54µ |

| 600 | 28 | M25 | 22-36µ |

| 1000 | 15 | M16 | 12-22µ |

| 1500 | 10 | M10 | 8-12µ |

| 2000 | 8 | 5-12µ | |

| 2500 | 6 | M6.3 | 4-8µ |

| 3000 | 5 | 2-6µ |

Vitrified Bond Wheels

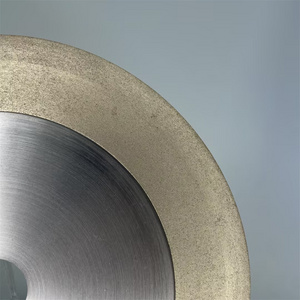

Vitrified bond is a vitreous binding material and generally contains pores inside while other materials contain no pores.Therefore vitrified bond wheels have excellent grinding ability and are superior in forming.

1. Characteristics of Vitrified Bond Wheels

- Wheels grinding ability and wheel life depend on the combination of bi nding material ,super abrasive mesh size, concentration, and porosity. The harder the bond, the longer wheel life is achieved.On the contrary, the softer the bond, better grinding ability is achieved because porosity becomes higher .Also higher concentration of abrasive, equates to longer wheel life.

- Automated processing is available because simultaneous operation of truing and dressing using rotary dresser on the grinding machine is possible.

- Cutting edges can be manipulated in such a manner that the surface finish of the part can be controlled.

- Diamond wheels have difficulty in truing and dressing with rotary dressers.Therefore surface finish depends on the mesh size of super abversive in the diamond wheel.

2. Applications of Diamond Wheels

- They are efficiently used for grinding difficult-to-machine materials such as PCD,PCBN,ceramis,etc.

- They are fenerally superior in grindding ability to metal bond wheels. Because the vitrified bond has no elasticity, it is better suited for tight tolerance applications than resin bond wheels.

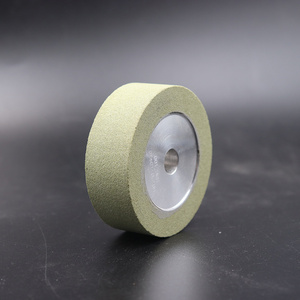

3. Appications of CBN Wheels

- They are used for grinding ferrous materials such as automotive parts(camshafts,crankshafts,gears, CVJ, etc.) , bearing parts, house hold appliance parts(compressors, motor shafts, etc.),and cutting tools.

- CBN abrasive has superior heat stability thus providing excellent performance in super high-speed grinding to process camshafts, crankshafts,etc.

| Packing | Carton, plastic bag,or as your request | ||||||

| Shipping | we use DHL,UPS,FEDEX,ect.to ship the goods,or according to the customer's requirement | ||||||

| Delivery time | about3-7days, for special time according to your quantity | ||||||

1. Quick Response: Your inquiry will be replied within 24 hours.

2. Competitive Price : Directly from factory to save your money.

3. after-sales warranty : Once there is problem after you received products, you can contact us in time. We will resolve it in short time.

4. Flexibility: Small orders are acceptable for quick delivery and to help you reduce stock cost.

5. OEM service: Custom fabrication according to your drawings ,samples or designs.