- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

kuntai

-

Model Number:

-

KT-WF-1800B

-

Dimension(L*W*H):

-

4800*2400*1500MM

-

Weight:

-

Contact

-

Certification:

-

CE ISO

-

Name:

-

China Automatic Film Laminating Machine

-

Glue Type:

-

Solvent based glue

-

OEM Service:

-

Yes

-

Color:

-

Blue, Customizable

-

Driven type:

-

electric

-

Warranty:

-

1 Year

-

Function:

-

Recycling Waste Textile

-

Material:

-

Stainless Steel

Quick Details

-

Voltage:

-

220V/380V

-

Power:

-

3KW

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

kuntai

-

Model Number:

-

KT-WF-1800B

-

Dimension(L*W*H):

-

4800*2400*1500MM

-

Weight:

-

Contact

-

Certification:

-

CE ISO

-

Name:

-

China Automatic Film Laminating Machine

-

Glue Type:

-

Solvent based glue

-

OEM Service:

-

Yes

-

Color:

-

Blue, Customizable

-

Driven type:

-

electric

-

Warranty:

-

1 Year

-

Function:

-

Recycling Waste Textile

-

Material:

-

Stainless Steel

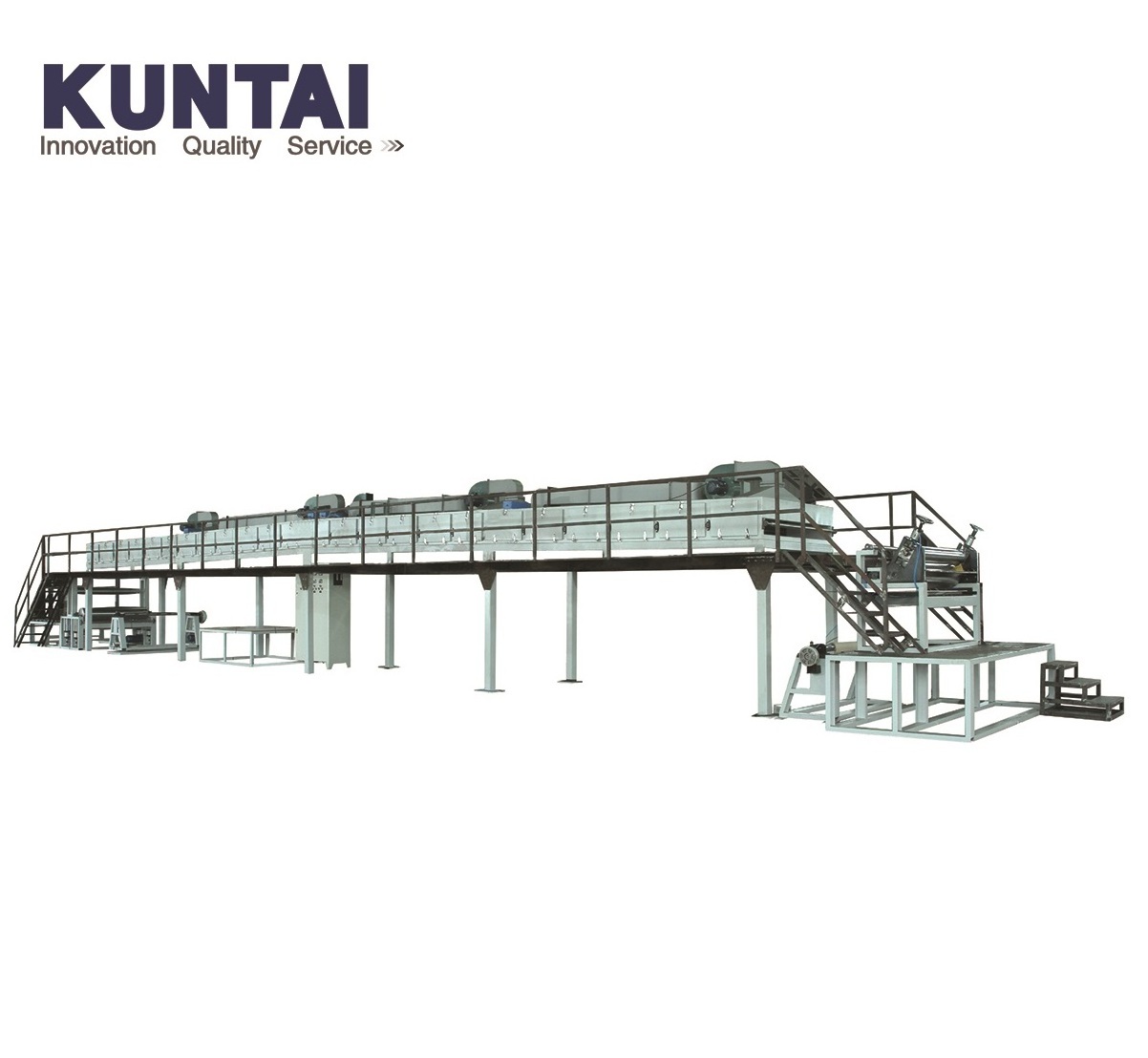

PE/PU/EVA/BOPP release paper coating machine

Key Features:

1.This kind of water based adhesive sticker laminating machine is applied for making self-adhesive or coating by adhesive sticker on the kraft paper,trademark,advertising,BOPP,masking tape,PE,non-woven fabric,PU,EVA,foam and etc.

2.The adhesive sticker lamination machine is suitable for auto interior,hand bag,luggage,light-fixture,advertisement,packaging industry,etc.

3.Full-automatic tension control, full-automatic temperature control, many coating die extruders are optional.

4.Winding and unwinding can be installed swing type replacement shaft, which can reduce the stop frequency and shorten stop time, work efficiency.

5.High accurate fine-tuning device to ensure the gluing precision

Our machine is customerized making, so pls inform us more information as below:

1 the base material

2 the width

3 unwinding and rewinding

4 coating material

5 how much gram of glue coated on every square of base material

6 heating method

7 coating speed

Application:

Glue Laminating Machine

91.8% Response Rate

Hot Melt Glue Foam Laminating Machine

95.8% Response Rate

automatic hydraulic plane fabric cutting machine

88 .8% Response Rate

1,Historical precipitation technological innovation.

32 years of rich experience for various industries to provide composite cutting equipment, fabric stamping equipment and other industry solutions.

2,Globalization after sales

Covering 5 continents with over 60 countries complete after sales service, no matter where you are, kuntai's service time is at your side?

3,Industry-specific customization

A strong team of engineers will make the best one-to-one customization for your product requirements to maximize the advantages of your product equipment.

4,Strong technical support.

The technical support of southeast university, the practice training of German engineers, and the team of dozens of experts are the technical guarantee for you to purchase the machine in kuntai.

5,High quality standards.

The IOS system certification, the eu CE certification and the us UL certification are the quality assurance for us. CTPM refined management is our guideline for high quality standards.

Packaging & Shipping of Fabric Laminating Machine:

Inner Package: Protective Film, etc

Outside Package: Plywood Case

Film laminating machines well packed with protective film and loaded in plywood case or export container;

English version operation manual and technical data;

One-Year-Period wear parts;

Tool kit