- Product Details

- {{item.text}}

Quick Details

-

Product Name:

-

Stock Solid Tungsten Bar Tungsten Rod Tungsten Carbide Rod

-

Material:

-

tungsten, W1, W2

-

Standard:

-

GB/T3875, ASTM B760

-

Density:

-

19.3g/cm3

-

Purity:

-

W1 ≥99.95%, W2 ≥99.92%

-

Boiling Point:

-

5927°C

-

Melting Point:

-

3410 °C

-

Application:

-

Industrial,medical,metallurgical,high temperature furnace,Aerospace

-

Certification:

-

ISO9001

-

Key Words:

-

Tungsten rod, tungsten bar

Quick Details

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

Xinkang

-

Model Number:

-

XK-WR 006

-

Product Name:

-

Stock Solid Tungsten Bar Tungsten Rod Tungsten Carbide Rod

-

Material:

-

tungsten, W1, W2

-

Standard:

-

GB/T3875, ASTM B760

-

Density:

-

19.3g/cm3

-

Purity:

-

W1 ≥99.95%, W2 ≥99.92%

-

Boiling Point:

-

5927°C

-

Melting Point:

-

3410 °C

-

Application:

-

Industrial,medical,metallurgical,high temperature furnace,Aerospace

-

Certification:

-

ISO9001

-

Key Words:

-

Tungsten rod, tungsten bar

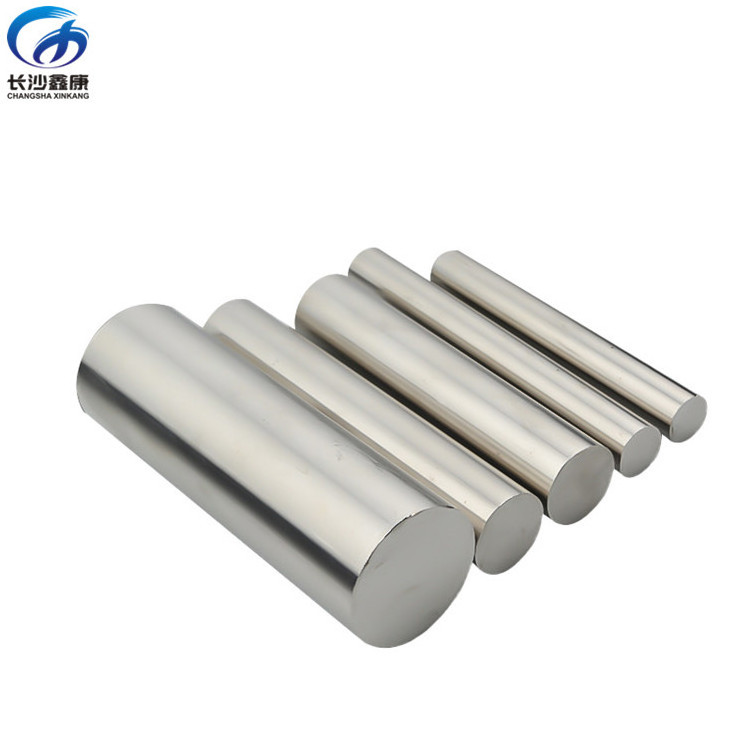

Product Show

Products Description

Stock Solid Tungsten Bar Tungsten Rod Tungsten Carbide Rod for Cutting Tools

|

Product Name

|

Stock Solid Tungsten Bar Tungsten Rod Tungsten Carbide Rod for Cutting Tools

|

|

|

|

|||

|

Material

|

99.95% tungsten

|

|

|

|

|||

|

Standard

|

ASTMB760-07, GB/T3875-83

|

|

|

|

|||

|

Melting Point

|

3410 °C

|

|

|

|

|||

|

Boiling Point

|

5927°C

|

|

|

|

|||

|

Density

|

19.3g/cm3

|

|

|

|

|||

|

Technique

|

cold rolled or hot rolled

|

|

|

|

|||

|

Delivery Time

|

3-15days

|

|

|

|

|||

|

Application

|

1.Tungsten bars are mainly used for processing tungsten parts or as a tool bit of processing lathe, conductors, steel-making burdening and additives;

2.They are also applied in crankshaft, cylinder burdening and electrodes for advanced automobiles; 3.They are also produced as components for manufacturing of guns, artillery, rockets, satellites, aircrafts and ships. In addition, tungsten bar can be also used as antiradiation material in nuclear industry.

4. Medical equipment, vacuum coating, electric vacuum stove electrode

5. Heat insulation screen, etc. as the radiation shielding material and radiation-protective equipment.

|

|

|

|

|||

Sizes and Tolerances

|

Surface

Size

|

Swag

|

|

Drawn

|

|

Chemical Cleaning/

Electrolytic Polishing

|

|

Ground

|

|

L Tolerance

|

||||

|

|

Dia Tolerance

|

Ovality

TOL

|

Dia

TOL

|

Ovality TOL

|

Dia TOL

|

Ovality TOL

|

Dia TOL

|

Ovality TOL

|

|

||||

|

0.2≤d<0.5

|

-

|

-

|

±0.01

|

0.01

|

±0.01

|

0.01

|

-

|

-

|

L<100±1.0

100≤L<300±1.5

300≤L<500±2.0

500≤L<1000±2.5

1000≤L<2000±5.0

|

||||

|

0.5≤d<0.8

|

-

|

-

|

±0.02

|

0.02

|

±0.02

|

0.02

|

±0.01

|

±0.01

|

|

||||

|

0.8≤d<1.0

|

-

|

-

|

±0.02

|

0.02

|

±0.02

|

0.02

|

±0.02

|

±0.02

|

|

||||

|

1.0≤d<1.8

|

-

|

-

|

±0.03

|

0.03

|

±0.03

|

0.03

|

±0.02

|

±0.02

|

|

||||

|

1.8≤d<3.5

|

-

|

-

|

±0.05

|

0.05

|

±0.05

|

0.05

|

±0.03

|

±0.03

|

|

||||

|

3.5≤d<5.0

|

±0.1

|

-

|

-

|

-

|

-

|

-

|

±0.05

|

±0.05

|

|

||||

|

5.0≤d<9.0

|

±0.2

|

-

|

-

|

-

|

-

|

-

|

±0.08

|

±0.08

|

|

||||

|

9.0≤d<13

|

±0.3

|

-

|

-

|

-

|

-

|

-

|

±0.10

|

±0.10

|

|

||||

|

13≤d<17

|

±0.4

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

-

|

||||

Hot Searches