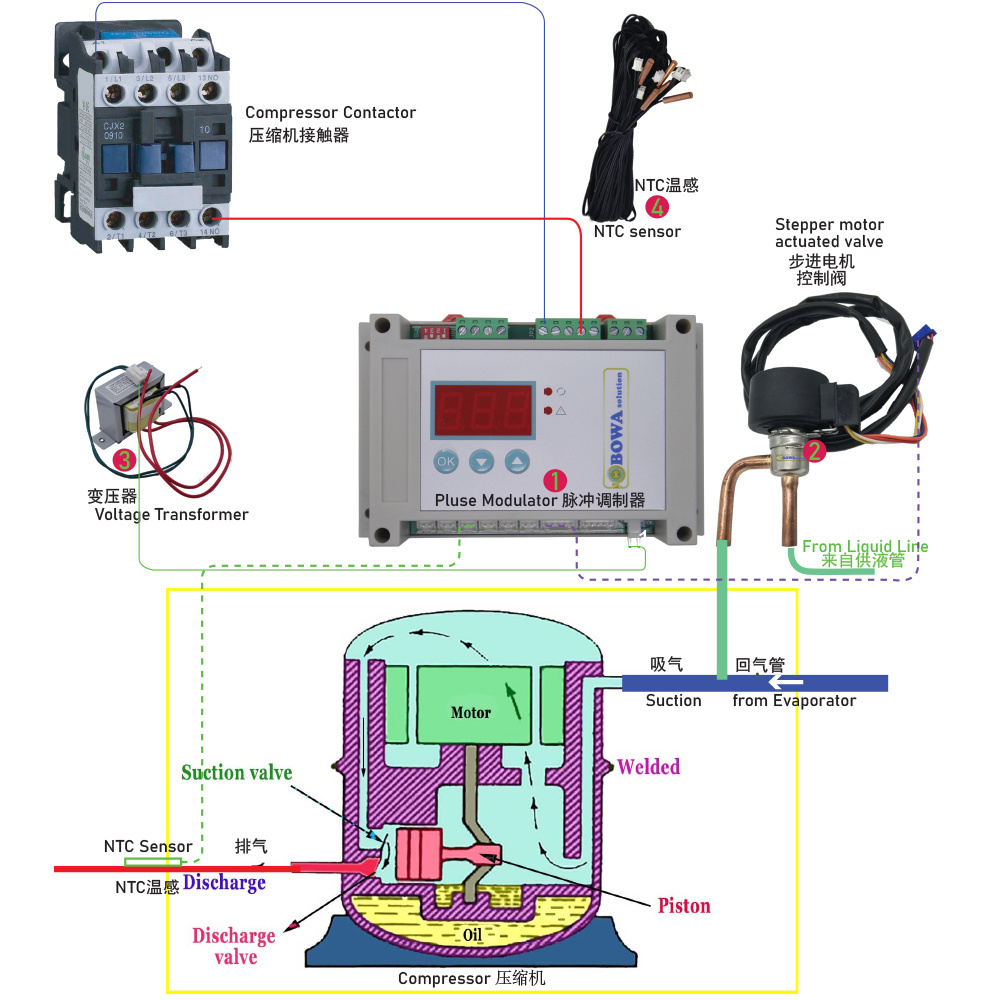

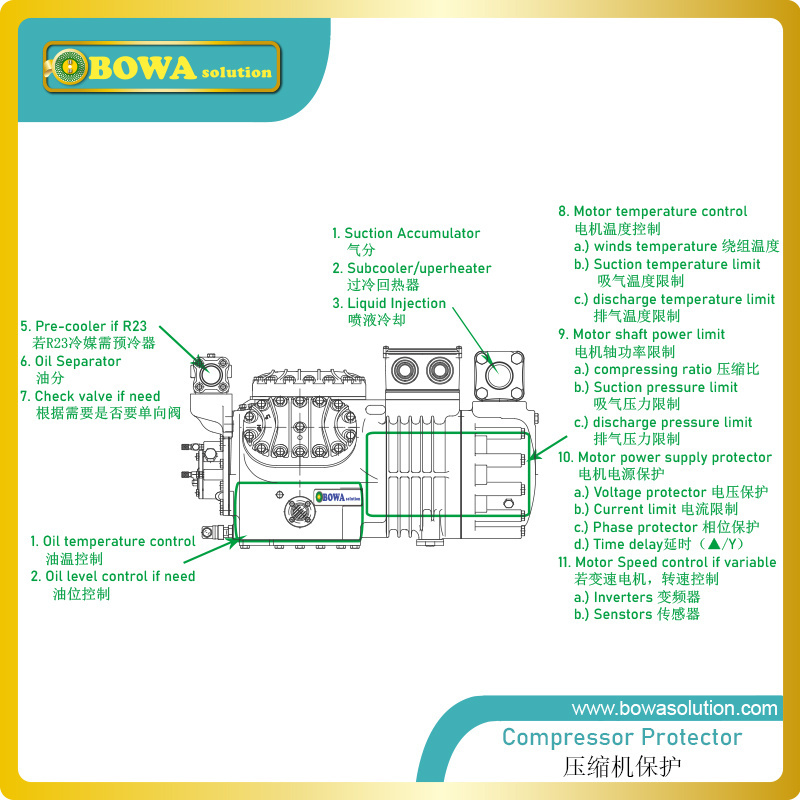

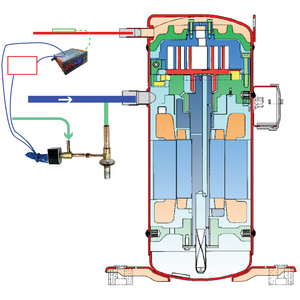

* Universal for chillers, freezers, heat pump,

air conditions and other climatd equipments

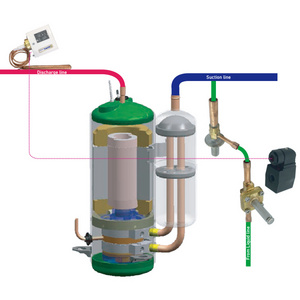

Rated capacities from 1.7 to 35.4 kW for R22

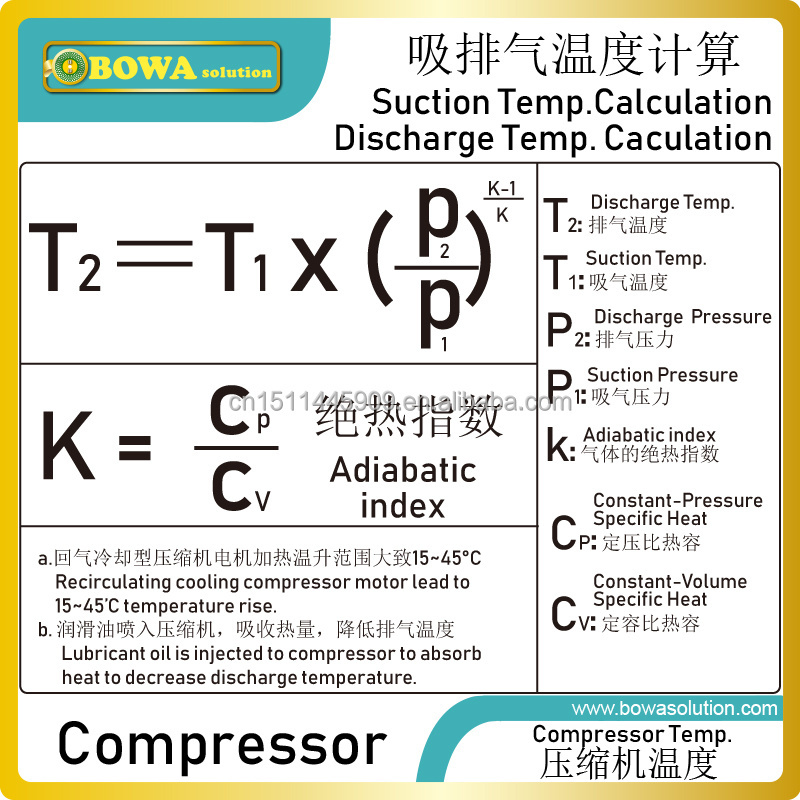

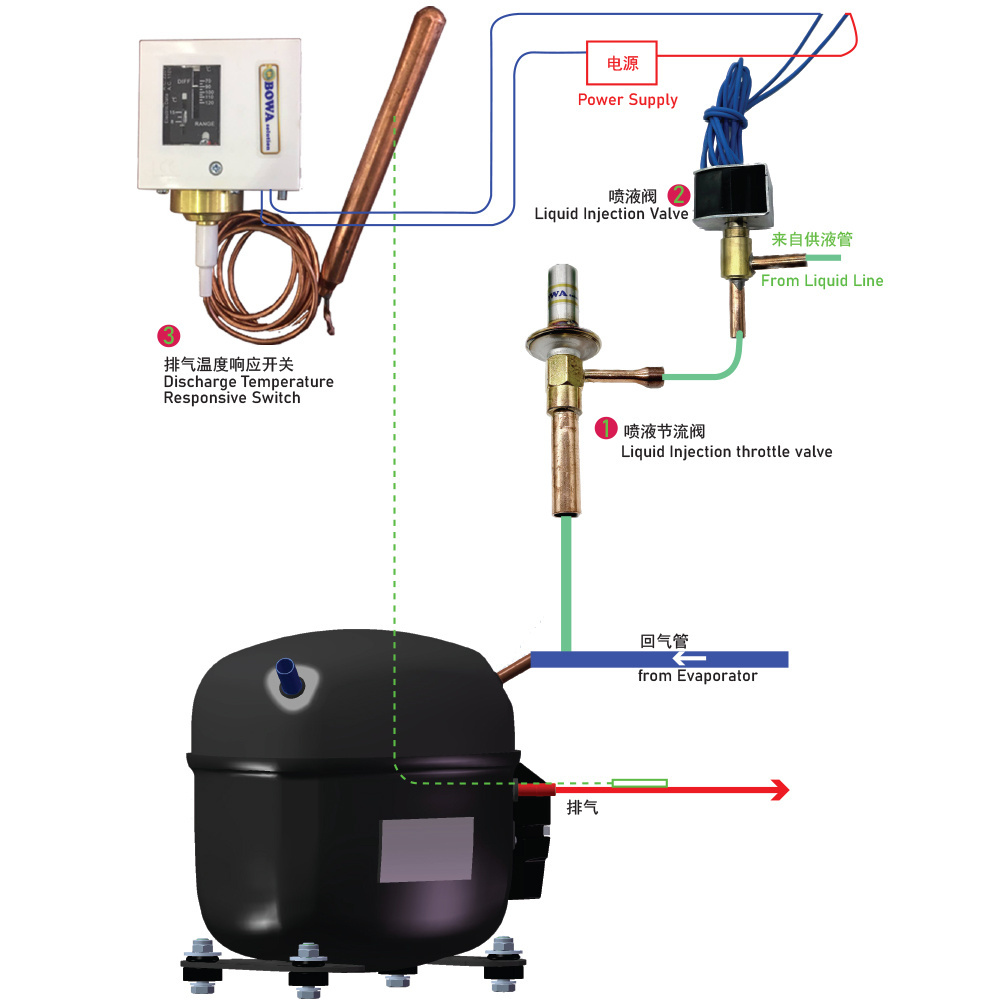

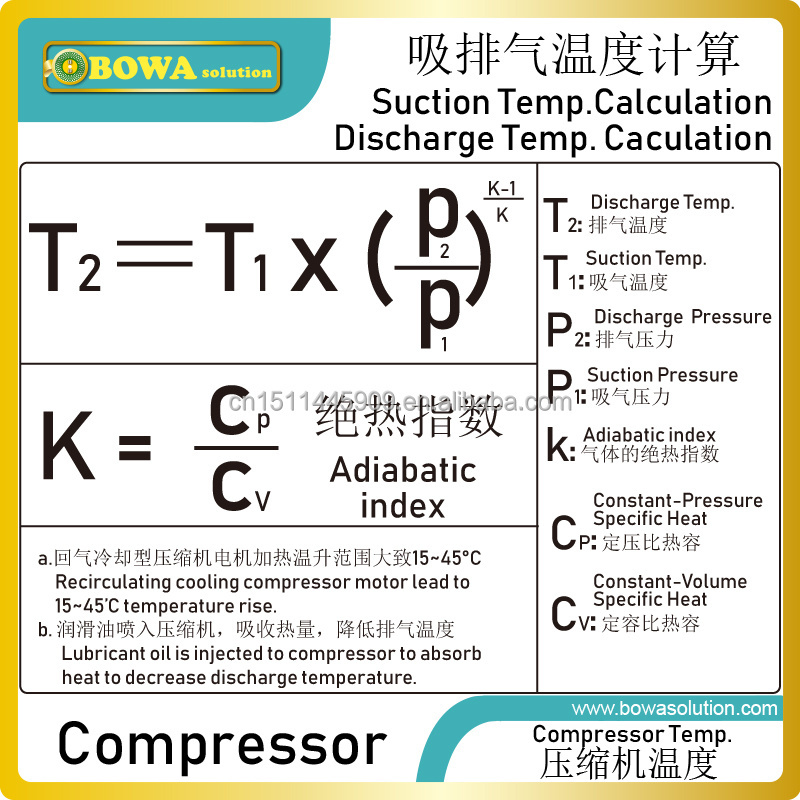

* Discharge temperautre response between 70'C ~ 120'C (adjustable)

* Intermediate pressure/ temp. is adjustable

* Different Iiquid injection throttle valve (different cooling capacity) is available

* Compatible with all common refrigerants, such as R410a, R32, R22, R134a, R23. etc.

*

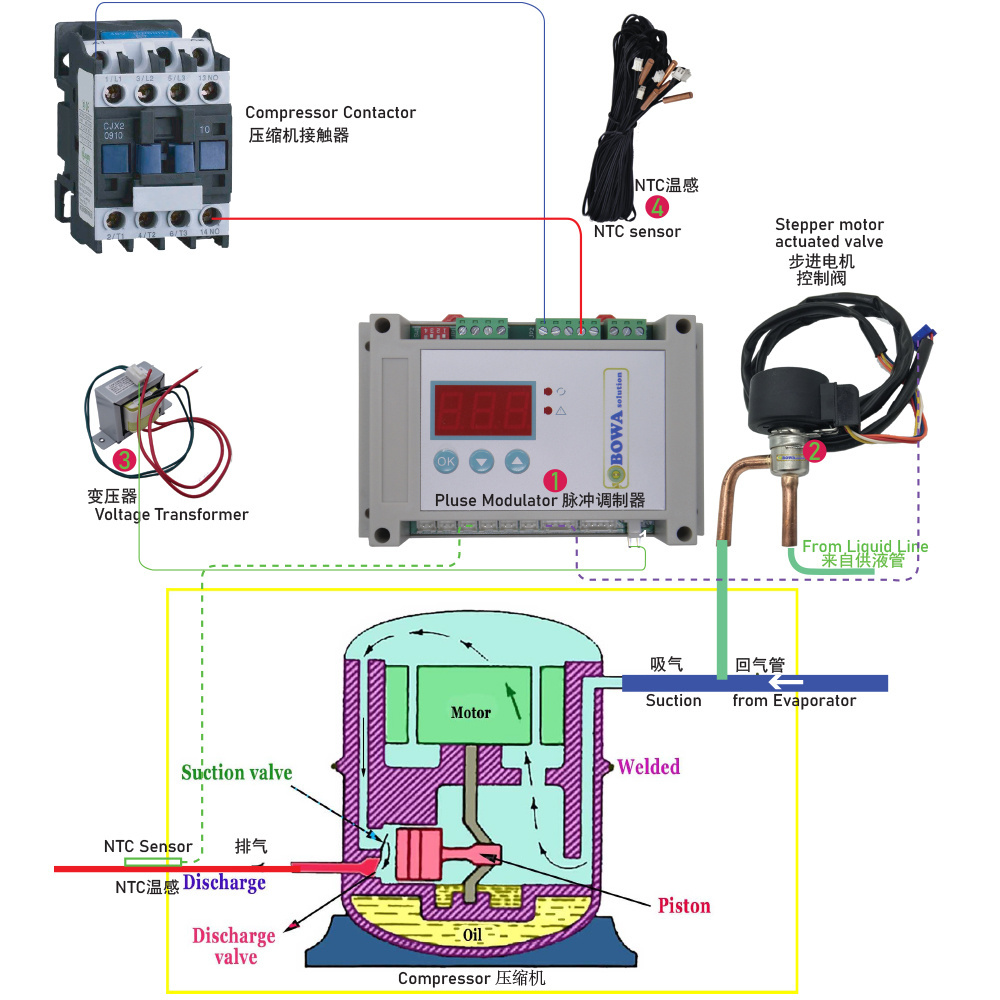

Simple operation and installation

* Easy replacement and adjustments

* Quick response

* Different voltage is optional

*

easier stocking,

easy capacity matching,

better service.

* Customized injection solution is available