- Product Details

- {{item.text}}

Quick Details

-

Spindle speed of side hole (r/min):

-

8160/4800/2800/1640

-

Taper of the main shaft of side hole:

-

B16

-

Side hole motor power(three phase):

-

750W, 440V, 50Hz, 2800r/min

-

Spindle speed of vertical hole(r/min):

-

5600

-

Motor power of vertical hole:

-

370W, 440V, 50Hz, 2800r/min

-

WEIGHT(kg):

-

650

-

Length * width * height(mm):

-

3100*1150*1800

-

Spindle speed of cutting machine(r/min):

-

3800

-

property:

-

ordinary single row

-

Weight:

-

650kg

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

YOMIN

-

Weight (KG):

-

650

-

Spindle speed of side hole (r/min):

-

8160/4800/2800/1640

-

Taper of the main shaft of side hole:

-

B16

-

Side hole motor power(three phase):

-

750W, 440V, 50Hz, 2800r/min

-

Spindle speed of vertical hole(r/min):

-

5600

-

Motor power of vertical hole:

-

370W, 440V, 50Hz, 2800r/min

-

WEIGHT(kg):

-

650

-

Length * width * height(mm):

-

3100*1150*1800

-

Spindle speed of cutting machine(r/min):

-

3800

-

property:

-

ordinary single row

-

Weight:

-

650kg

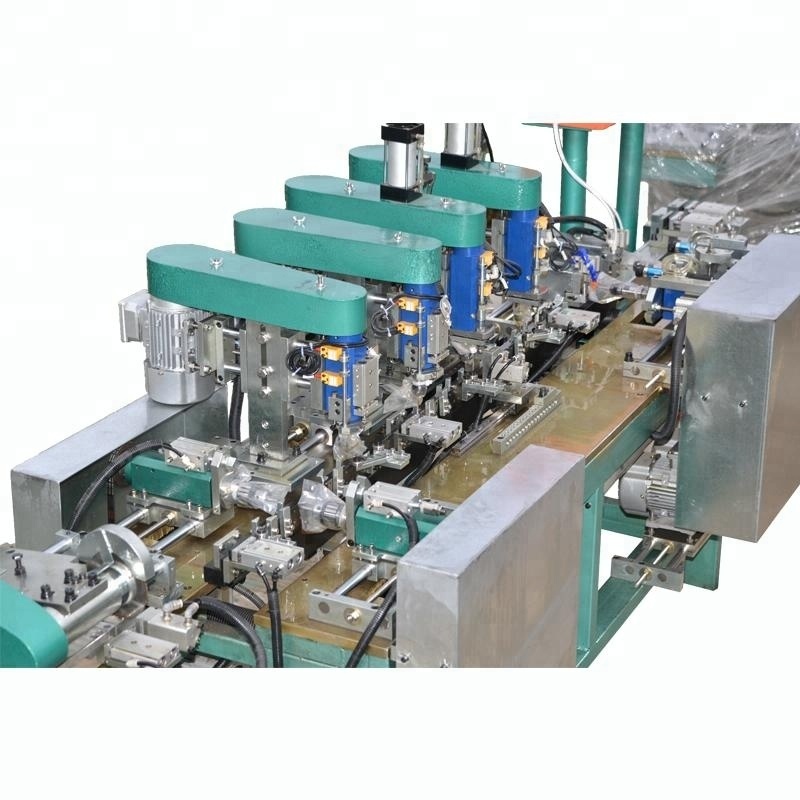

Automatic cutting, drilling and production of brass busbar terminals

Main structure of automatic terminal machine

The device is mainly composed of the following components: 0 servo motor; 1. work table, 2. distribution box, 3. ball screw and slideway, 4. side hole work station, 5. vertical drilling station, 6. thread attack screw position, 7. chamfering station, 8. cutting station. 01.07.08.09.015 stepped back to the origin of the cylinder; 2 feeding to the cylinder; 03.04.05 feeding auxiliary clamping cylinder; 6 lateral drilling auxiliary pressing cylinder; 10 vertical drilling thrust cylinder; 11.012 chamfer cutting machine 13 cylinder propulsion; propulsion cylinder; 14 side drilled holes into the cylinder; 016 point positioning cylinder

|

1, Sidetracking large hole mechanism |

2 SETS |

|

|

Maximum borehole diameter of side hole( mm ) |

10 |

|

|

Push stroke of side hole cylinder( mm ) |

20 |

|

|

Spindle speed of side hole ( r/min ) |

8160,4800,2800,1640 |

|

|

Taper of the main shaft of side hole |

B16 |

|

|

Side hole motor power( three phase ) |

750W, 440V, 50Hz, 2800r/min |

|

|

2, Non shift vertical drilling mechanism |

2 sets |

|

|

Maximum hole diameter of vertical hole( mm ) |

5.5 |

|

|

The longest stroke of the vertical hole position cylinder( mm ) |

20 |

|

|

Spindle speed of vertical hole( r/min ) |

5600 |

|

|

Vertical hole spindle collet |

ER16 |

|

|

Motor power of vertical hole( three phase ) |

370 W, 44 0V, 50Hz, 2800r/min |

|

|

3, Non shift tapping mechanism |

2 sets |

|

|

Maximum wire attack diameter of wire tapping machine |

M6 |

|

|

Motor power of wire tapping machine( three phase ) |

250 W, 44 0V, 50Hz, 140 0r/min |

|

|

Spindle speed of wire tapping machine(r/min) |

1400 |

|

|

Tapping machine spindle collet station |

ER16 |

|

|

4, Chamfering mechanism |

2 sets |

|

|

Maximum stroke of chamfering cylinder( mm ) |

20 |

|

|

Maximum cutter diameter of chamfering position( mm ) |

6 |

|

|

Rotating speed of chamfered main shaft( r/min ) |

1400 |

|

|

Chamfering motor power( three phase )× 2 |

250W, 440V, 50Hz, 1400r/min |

|

|

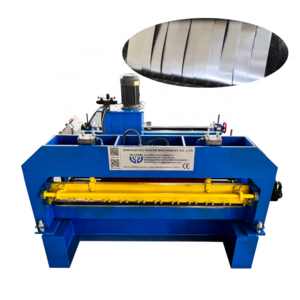

5, Cutting mechanism |

1 set |

|

|

Spindle speed of cutting machine( r/min ) |

3800 |

|

|

Maximum stroke of cutting position cylinder( mm ) |

50 |

|

|

Cutting motor power( three phase ) |

0.75kw, 440V, 50Hz, 2800r/min |

|

|

6, Distribution control box |

1 SET |

|

|

Programmable controller(PLC) |

1 SET JANPAN KEYENCE |

|

|

Touch screen

|

1 SET TAIWAN WEINVIEW |

|

|

Servo drive and motor |

1 SET 400W Chinese xinje |

|

|

Switching Mode Power Supply |

1 SET 150W, TAIWAN MW |

|

|

Relay |

7 SETS JANPAN OMRON |

|

|

AC contactor |

6 SETS JANPAN FUJI |

|

|

7, The size and weight of the equipment 1 SET |

||

|

Length * width * height(mm) |

3100*1150*1800 |

|

|

WEIGHT (kg) |

650 |

|

1 Where is your factory?

Our factory is located in Qiaoqian Industry Area, Liushi Town, Yueqing City, Zhejiang Province, 325603 China.

2 Are you manufacturer or business?

We are manufacturer established in 2002, and have over 16 years production experience.

3. Can I ask for samples?

Yes

4. What's the warranty of your products?

18 months

5. What's the lead time?

Depend on the quantity and model of the order, normally it takes around 2-3 days, but the

exact lead time should be discussed with our sales.

6. How about the MOQ, Payment term, Delivery port, and shipping date?

1)MOQ: 100 pcs/item based on existing packing.

2)T/T-30% deposit and 70% against copy of BL

3)L/C is also acceptable

4)Ningbo/Shanghai