- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

depends on the model

-

Weight:

-

5200 KG

-

Product name:

-

Coal Washing Plant

-

Keywords:

-

Coal Process Plant

-

Application:

-

Mining Separation

-

Color:

-

Customers' Requirements

-

Capacity:

-

1-500tph

-

Quality:

-

High Reputation

-

Feature:

-

High Recovery Rate Easy

-

Installation:

-

Engineer Guidance

-

Price:

-

Negotiable

-

After sale service:

-

Engineer Overseas Service

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Walker

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

depends on the model

-

Weight:

-

5200 KG

-

Product name:

-

Coal Washing Plant

-

Keywords:

-

Coal Process Plant

-

Application:

-

Mining Separation

-

Color:

-

Customers' Requirements

-

Capacity:

-

1-500tph

-

Quality:

-

High Reputation

-

Feature:

-

High Recovery Rate Easy

-

Installation:

-

Engineer Guidance

-

Price:

-

Negotiable

-

After sale service:

-

Engineer Overseas Service

Product Description

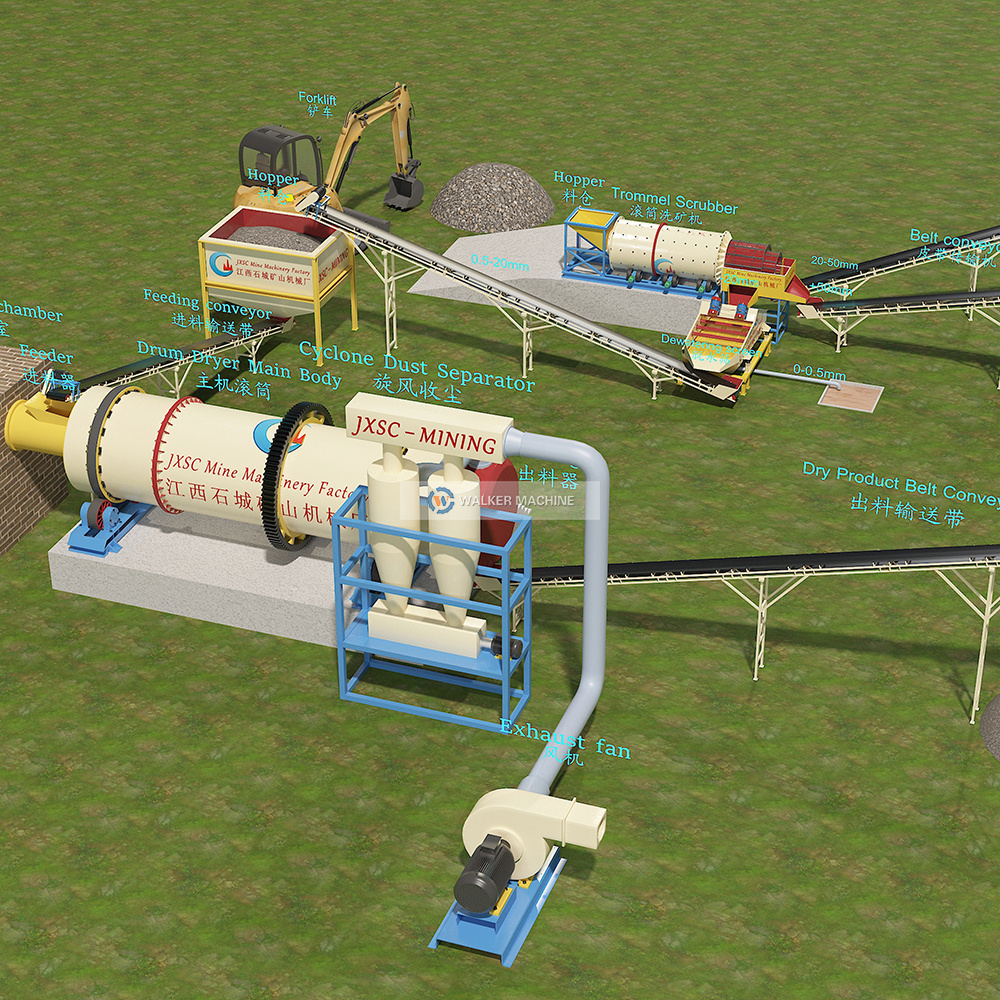

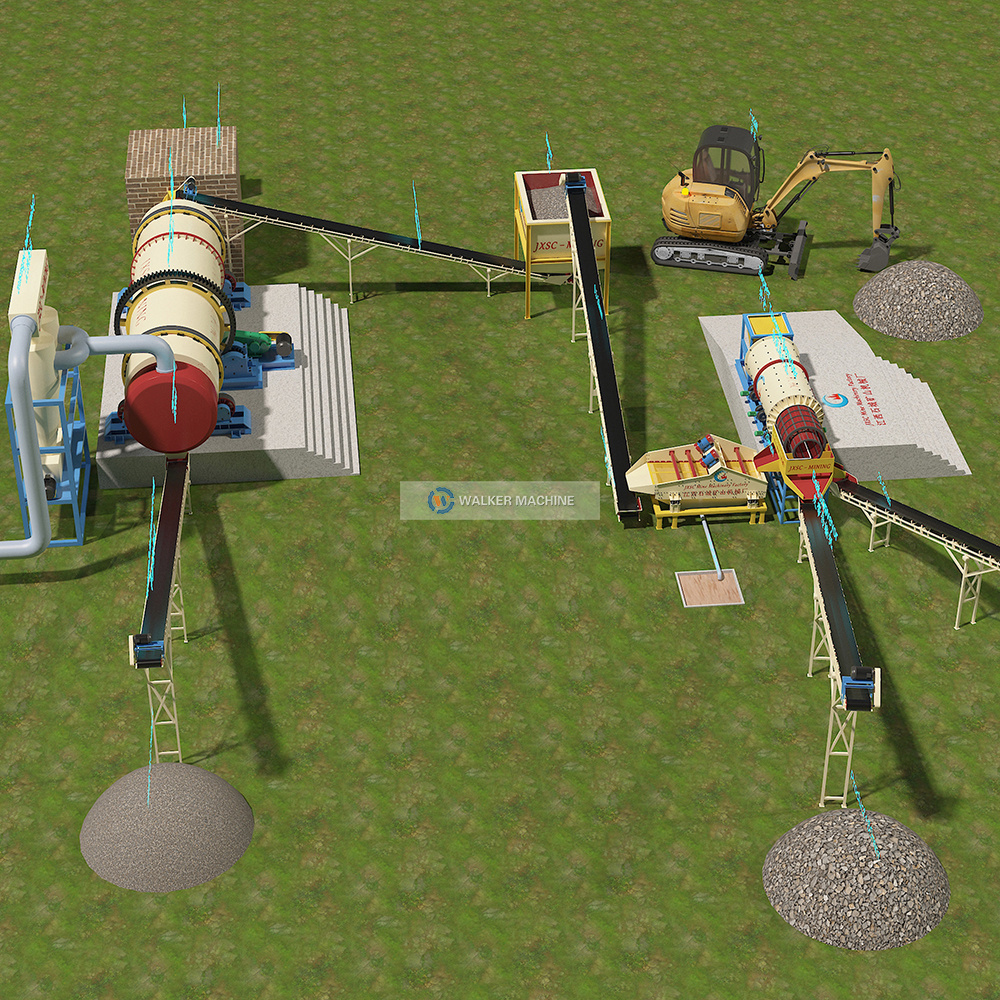

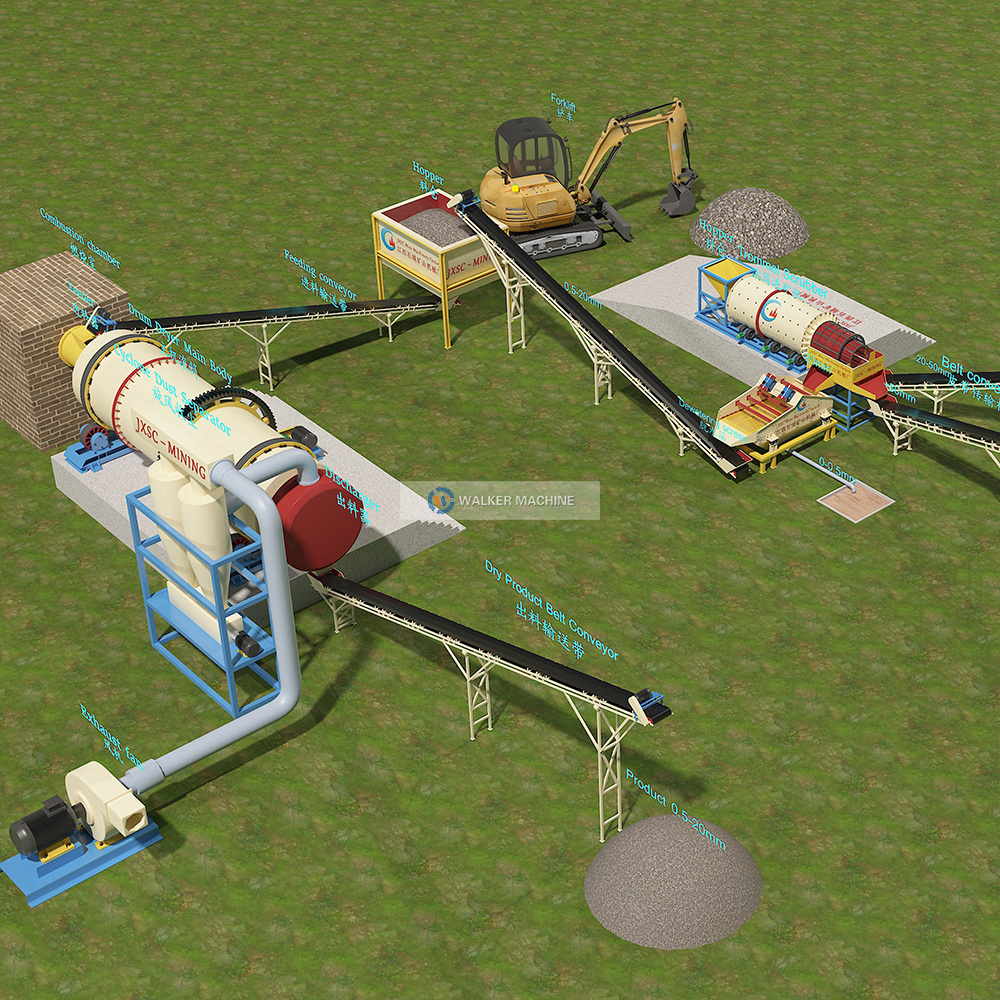

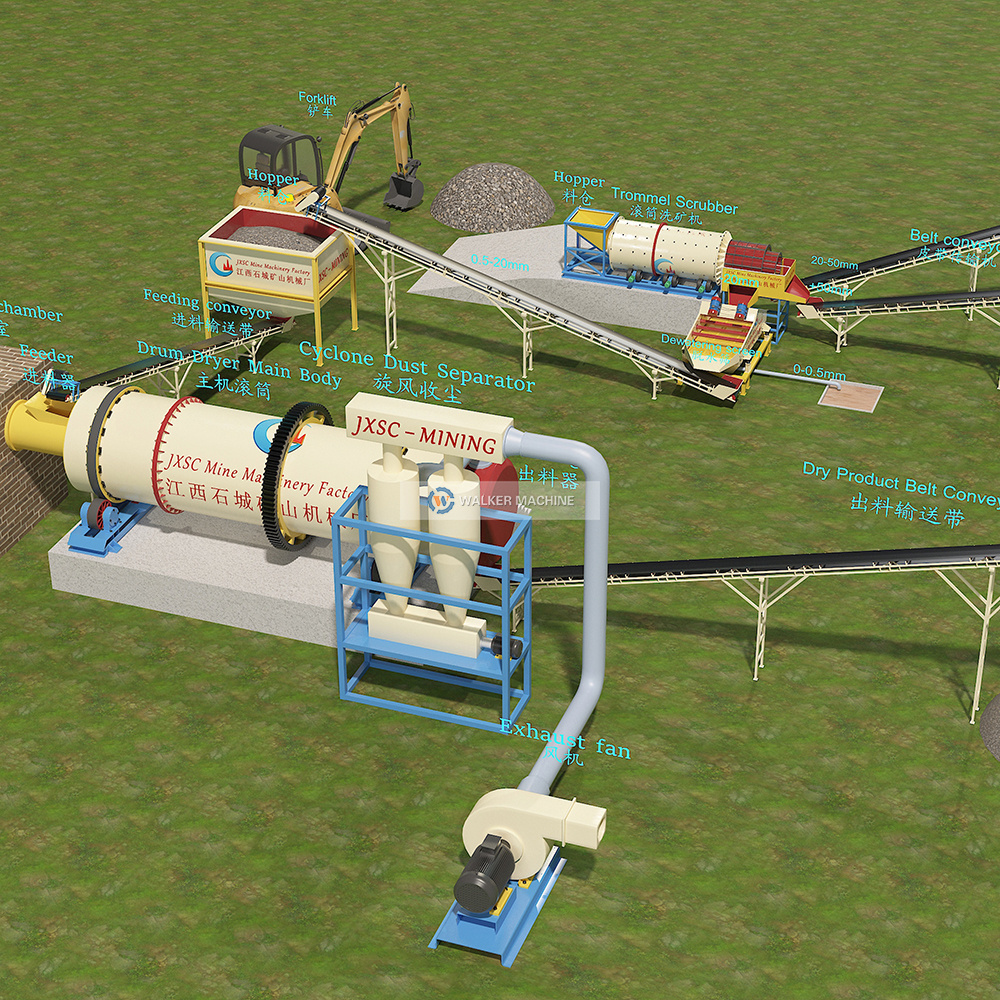

Overview

The coal preparation plant (CPP) is a facility that washes coal of soil and rock, crushes it into graded-sized chunks (sorting), stockpiles grades preparing it for transport to market.

Coal Washing Plant

1. Coal, contain with clay

2. Feeding size 0-150mm

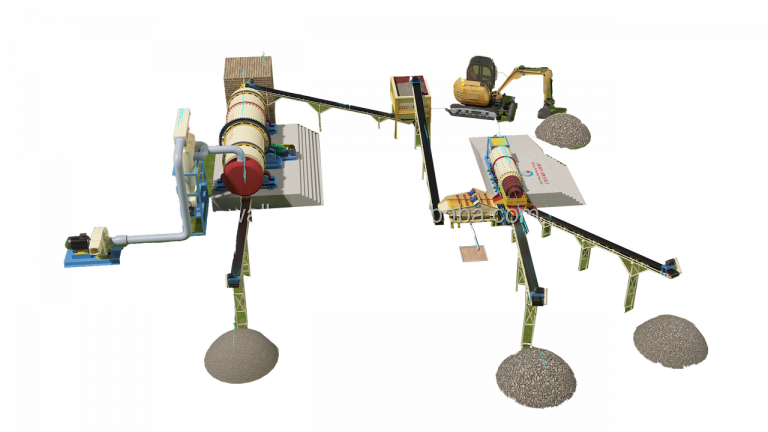

Highlights of this coal wash processing plant

1. Coal Ore washing

2. Trommel Scrubber screening and separating coal ores, and get 3 different sizes output.

3. Using Rotary Dryer to get dry coal products

Customer’s requirements:

1. Washing

2. Screen for 3 outputs

3. Rotary dryer for drying coal

Screen output:

1. Above 50mm

2. 20-50mm

3. Below 20mm

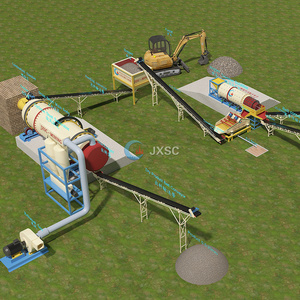

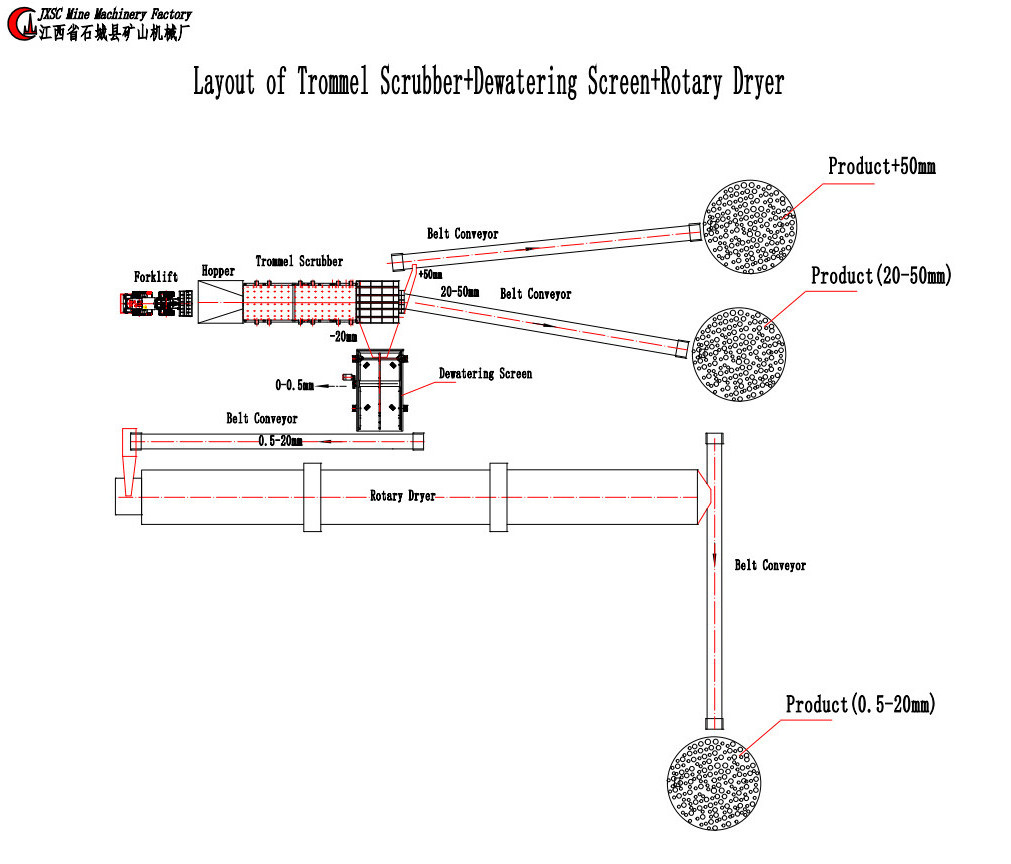

Processing Flow Overview

▼

1.

Excavator or loader feed raw materials to the hopper of trommel scrubber, here trommel scrubber with 2 layers screen at the end. After washing off clay, screen three outputs: above 50mm,20-50mm, and below 20mm. Above 50mm and 20-50mm, outputs are transported to another place by belt conveyors.

2.

Below 20mm go to the dewatering screen by gravity flow. Here put the dewatering screen lower level than the trommel scrubber, so that 0-20mm slurry can flow to the dewatering screen by height difference.

3.

Over screen materials of dewatering screen are sent to rotary dryer system for drying coal by feeding conveyor.

4.

The finished product after drying is transported by discharging conveyor.

Main Product

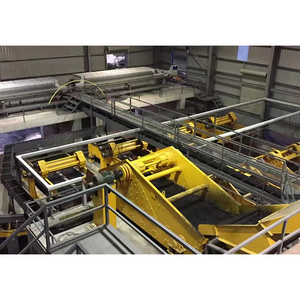

Successful cases

|

10TPH Coal Process Plant

|

Packing & Delivery

●Ways Of Packing

1.Small parts packed in the wooden cases.

2.Big parts packed by plastic membrane.

3.The whole big machine is loaded in the container.

● Shiping by sea/air freight

or any way the customer requires.

Company Introduction

Jiangxi walker Machinery Co.,Ltd, are a professional manufacturer of complete set mining equipments, a sub-company of JXSC mine machinery factory in Jiangxi province.professional at providing complete set processing equipments for Gold ore /Tin ore /Tungsten ore /Iron ore / Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set small lab mining machines.

Our core advantages as below:

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

1.+30years history factory at mining machinery

2.Provide engineer team after sale service

3.Provide complete set mineral processing plant

4.Provide sample testing service in factory lab for free

5.Provide professional ming soolution consulting

1.Inquiry and consulting support.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

2.Ore sample testing support.

3.View our Factory.

4.Design Flowchart.

1.Training how to instal the machine, training how to use the machine.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

2. 1 year warranty .

3.Engineers available to service machinery overseas.

FAQ

●

Pre-sales service:

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

● Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

● After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

● Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

● How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every grinder before delivery.

● How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

● How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 30% deposit, 70% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Hot Searches