- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

PQ Pack

-

Dimension(L*W*H):

-

1885mm*720mm*1560mm

-

Weight:

-

450 KG

-

Certification:

-

CE

-

Marketing Type:

-

Hot product 2022

-

Product name:

-

Cellophane Wrapping Machine

-

Packing Material:

-

BOPP film and gold tear tape

-

Packing Speed:

-

40~80 packs/min

-

Max Packing Size:

-

(L)60-240(W)30-120(H)10-60mm

-

Eletric Supply & Power:

-

220V 50Hz 5kw

-

MOQ:

-

1

Quick Details

-

Packaging Type:

-

Cartons, case

-

Packaging Material:

-

BOPP film

-

Driven Type:

-

Pneumatic

-

Voltage:

-

220V

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

PQ Pack

-

Dimension(L*W*H):

-

1885mm*720mm*1560mm

-

Weight:

-

450 KG

-

Certification:

-

CE

-

Marketing Type:

-

Hot product 2022

-

Product name:

-

Cellophane Wrapping Machine

-

Packing Material:

-

BOPP film and gold tear tape

-

Packing Speed:

-

40~80 packs/min

-

Max Packing Size:

-

(L)60-240(W)30-120(H)10-60mm

-

Eletric Supply & Power:

-

220V 50Hz 5kw

-

MOQ:

-

1

Product Overview

PQ-300A Cellophane Wrapping Machine

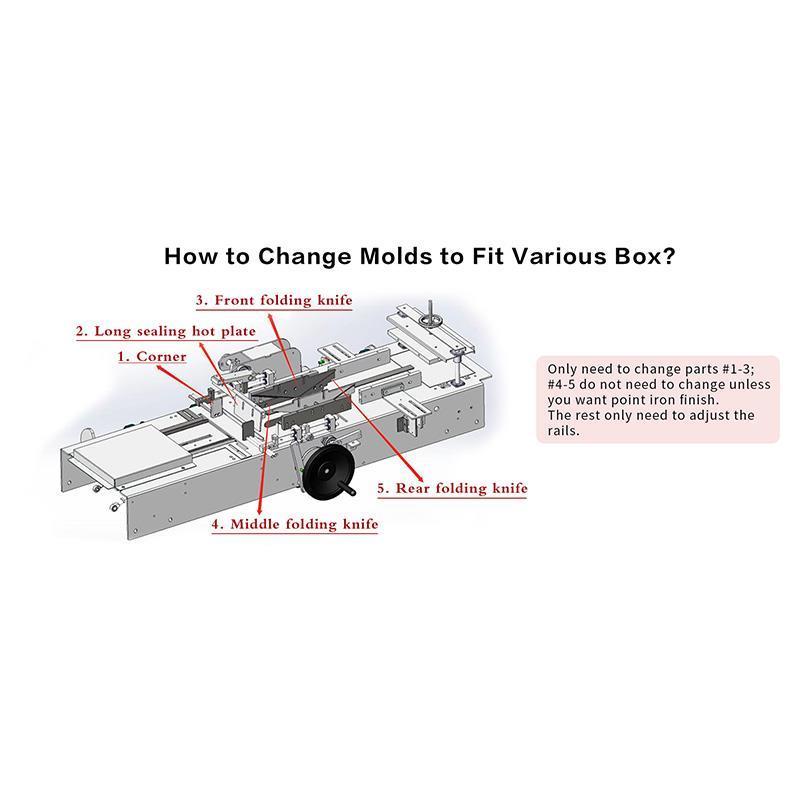

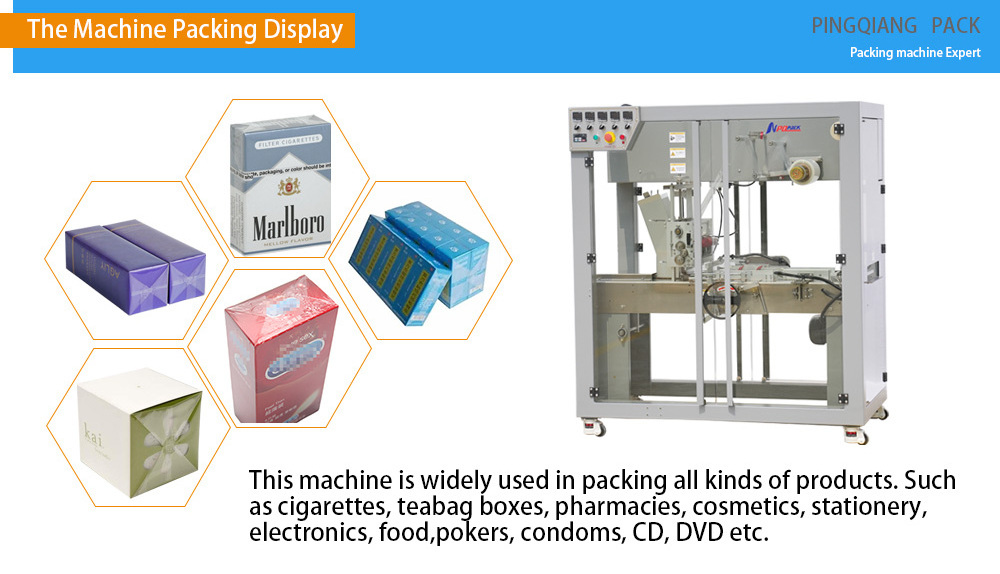

This machine is suitable for automatic film packaging of single box items in various industries (with golden stay wire). The

overall frame of the machine adopts carbon steel plastic spraying, floor multi opening safety door structure, and horizontal push box structure. It is simple to replace the mold.

The size is adjusted by hand to adjust the distance at many places, that saves the time of changing the mold. The fixed film is fixed by hand shaft roller, which makes the film changing simpler and faster.

overall frame of the machine adopts carbon steel plastic spraying, floor multi opening safety door structure, and horizontal push box structure. It is simple to replace the mold.

The size is adjusted by hand to adjust the distance at many places, that saves the time of changing the mold. The fixed film is fixed by hand shaft roller, which makes the film changing simpler and faster.

FEATURES AT A GLANCE

1. This machine is a full-automatic high-speed transparent film packaging equipment, which adopts the flat push packaging mode. All wrapping and heat sealing actions are completed by cam and cylinder transmission, with the characteristics of high speed and stable operation.

2. changing the mold can pack articles of different sizes. The newly designed quick adjustment structure makes it easier and faster to replace the mold.

3. this machine adopts all aluminum alloy oxidation film cutting knife holder and single rotation film cutting knife. The film cutting is accurate and flat, and there is no need to replace the film cutting mechanism for large and small products.

4. the frequency converter is used to adjust the packaging speed, which can reach 30 ~ 70 packages / minute according to different packaging items.

5. it is equipped with a double-sided anti wrinkle device to make the film packaging more close to the body and more beautiful.

6. quick disassembly and assembly pull wire reel, with the function of composite adhesive laser anti-counterfeiting and

unpacking line, which really plays the role of anti-counterfeiting and moisture-proof.

7. the machine adopts two kinds of feeding mechanisms: automatic feeding and manual feeding. The automatic feeding can be connected with the fully automatic unmanned production line.

8. the automatic feeding mechanism has the shutdown function when box is used up, and is equipped with a blocking torque overload protection device and an upper and lower double-layer air blowing auxiliary lower film device.

9. the imported stainless steel integrated panel is adopted, and the integrated electrical box is installed on the top (to

completely isolate the electrical and Mechanical).

10. the whole machine adopts acrylic safety cover.

3. this machine adopts all aluminum alloy oxidation film cutting knife holder and single rotation film cutting knife. The film cutting is accurate and flat, and there is no need to replace the film cutting mechanism for large and small products.

4. the frequency converter is used to adjust the packaging speed, which can reach 30 ~ 70 packages / minute according to different packaging items.

5. it is equipped with a double-sided anti wrinkle device to make the film packaging more close to the body and more beautiful.

6. quick disassembly and assembly pull wire reel, with the function of composite adhesive laser anti-counterfeiting and

unpacking line, which really plays the role of anti-counterfeiting and moisture-proof.

7. the machine adopts two kinds of feeding mechanisms: automatic feeding and manual feeding. The automatic feeding can be connected with the fully automatic unmanned production line.

8. the automatic feeding mechanism has the shutdown function when box is used up, and is equipped with a blocking torque overload protection device and an upper and lower double-layer air blowing auxiliary lower film device.

9. the imported stainless steel integrated panel is adopted, and the integrated electrical box is installed on the top (to

completely isolate the electrical and Mechanical).

10. the whole machine adopts acrylic safety cover.

PRODUCT SPECIFICATIONS

|

No

|

Item

|

Data

|

|

1

|

Packing Material

|

BOPP film and gold tear tape

|

|

2

|

Packing Speed

|

30~70 packs/min

|

|

3

|

Maximum package size

|

(L)50-250×(W)30-150×(H)15-70mm (length+Height(mm)≤280,width+Height (mm)≤180)

|

|

4

|

Power supply and total power

|

220V 50Hz 4.5kw

|

|

5

|

Machine weight

|

350kg

|

|

6

|

Machine dimensions

|

(L)1500×(W)850×(H)1700mm

|

PRODUCT CONFIGURATION

CE Brand Roller

AIRTAC Electron Magnetic Valve

AIRTACK Cylinder

SALES AND SERVICE NETWORK

Successful Project

PQ-280 Cigarette Box Wrapping

Side Sealing Packing Machine

PQ-450 Cellophane Wrapping Machine

If you need any video,pls contact us. We will send original video to you. We support all kinds of cellophane wrapping machines and shrink film packing machines in China.

SIMILAR PRODUCTS

FAQ

Q1:Are you a factory or trading company?

A1:We are the factory, and especially R&D, manufacture and sell various packing equipments. We have engaged in the packing R&D and production for over 10 years.

Q2:Why we should choose your company?

A2:We are professional in packing machines for over 10 years, and we provide better after-sales service. No risk for our deal.

Q3:How can guarantee your machines’ quality?

A3:Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking staff by yourself in China.

Q4:Is this machine safe?

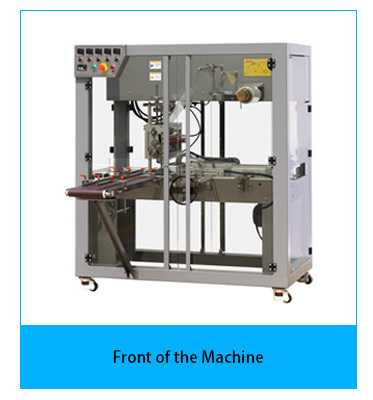

A4:Our machines are better in safety than our competitors. You can see all electric parts and wires are arranged at the top of the machine. No children and pets can reach the electric parts. Avoid electric shock

Q5:How soon can I get my machines?

A5:We can send the in-stock machines within 48 hours; For new machines, normally It’s about 15-20 days.

Q6:Can you design the machine according to our requirements?

A6:Yes. We not only can customize the machine according to your technical drawing, but also can design new machine according to your requirements.

Q7:Can you offer overseas technical support?

A7:Yes. We usually provide on-line support. We have more than 5 engineers who have passports, and have enough experience to provide service overseas.

Q8:Can I visit your factory?

A8:Welcome to our factory! We will arrange pick-up services in Shanghai.

Q9:Would I have a discount if I needed a large quantity?

A9:Our company is looking for agents, welcome to contact us with the agent policy.

A1:We are the factory, and especially R&D, manufacture and sell various packing equipments. We have engaged in the packing R&D and production for over 10 years.

Q2:Why we should choose your company?

A2:We are professional in packing machines for over 10 years, and we provide better after-sales service. No risk for our deal.

Q3:How can guarantee your machines’ quality?

A3:Before delivery, we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking staff by yourself in China.

Q4:Is this machine safe?

A4:Our machines are better in safety than our competitors. You can see all electric parts and wires are arranged at the top of the machine. No children and pets can reach the electric parts. Avoid electric shock

Q5:How soon can I get my machines?

A5:We can send the in-stock machines within 48 hours; For new machines, normally It’s about 15-20 days.

Q6:Can you design the machine according to our requirements?

A6:Yes. We not only can customize the machine according to your technical drawing, but also can design new machine according to your requirements.

Q7:Can you offer overseas technical support?

A7:Yes. We usually provide on-line support. We have more than 5 engineers who have passports, and have enough experience to provide service overseas.

Q8:Can I visit your factory?

A8:Welcome to our factory! We will arrange pick-up services in Shanghai.

Q9:Would I have a discount if I needed a large quantity?

A9:Our company is looking for agents, welcome to contact us with the agent policy.

Hot Searches