- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

China

-

Weight:

-

4500 kg

-

Product name:

-

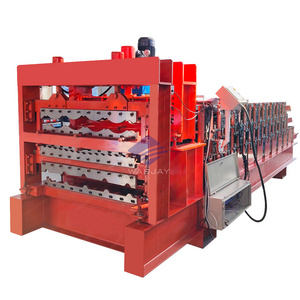

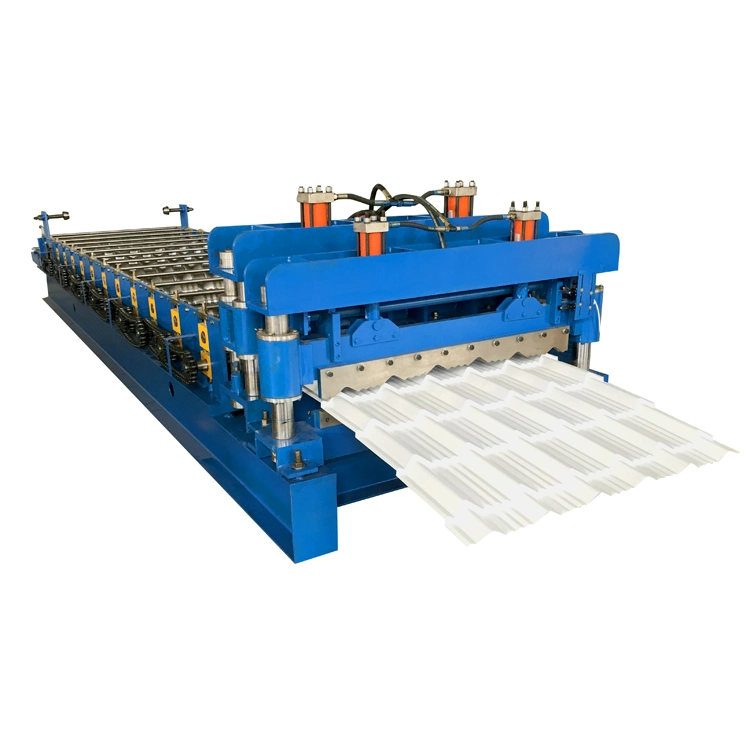

Roofing Sheet Machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

-

Usage:

-

Galvanize roof sheets machine

Quick Details

-

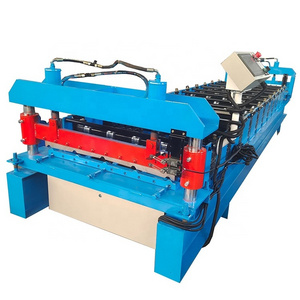

Type:

-

Tile Forming Machine

-

Tile Type:

-

Roof

-

Production Capacity:

-

30 m/min

-

Rolling thinckness:

-

Other

-

Place of Origin:

-

China

-

Weight:

-

4500 kg

-

Product name:

-

Roofing Sheet Machine

-

Color:

-

Client's Request

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

High Grade No.45 Forged

-

Cutting blade material:

-

Cr 12 High Grade Steel

-

Suitable to process:

-

Color Steel Plate

-

Screen:

-

Color touch screen

-

Cutting type:

-

Hydraulic Cutting

-

Usage:

-

Galvanize roof sheets machine

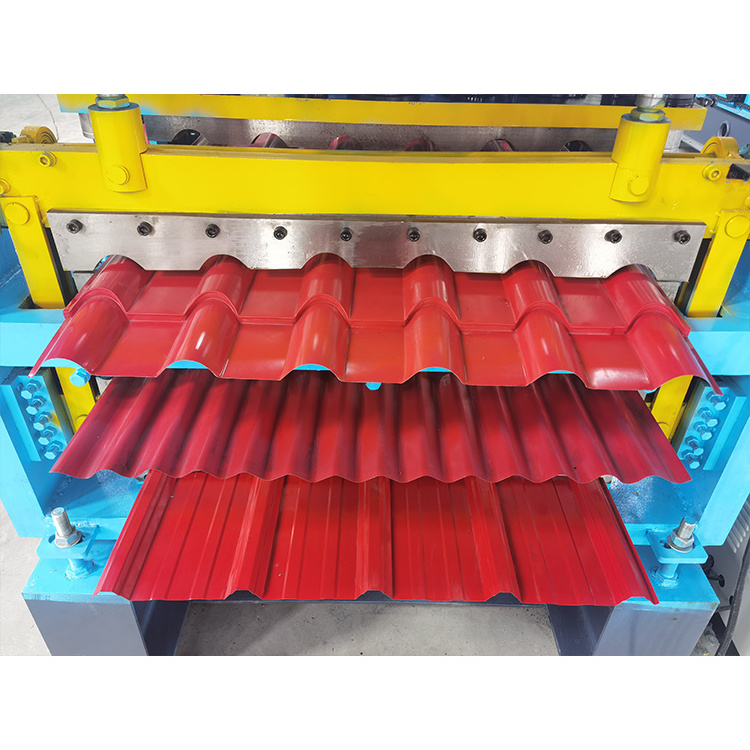

Products Description

Features

1. The main parts: roll forming machine; molding press; cutting machine; PLC computer control; hydraulic system.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer's requests.

2. The machine is stable, with no noise, no shake.

3. Controlling by computer, PLC display, the operation is easy, running is steady and reliable, endurable.

4. Cutting machine is characterized by stable driving, easy operation.

5. The hydraulic system uses the CDF-10 hydraulic pump, long operating life, no noise.

6. Material: galvanized, colored steel or aluminum coil.

7. We can make and design the kinds of roll forming machines according to customer's requests.

Working Process

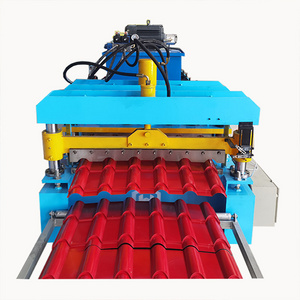

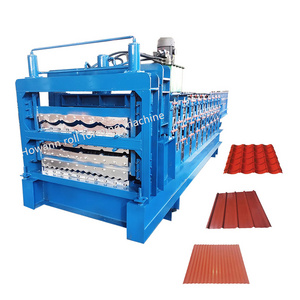

Specification

|

NO.

|

Item

|

Specification

|

|

Material |

Raw material

|

Galvanized steel or PPGI

|

|

|

Thickness

|

0.3-0.7 mm

|

|

Decoiler |

Operation

|

Manual or Hydraulic

|

|

|

Weight capacity

|

3T 5T 7T 10T

|

|

Machine |

Roller station

|

10-14 or depend on customer' drawing

|

|

|

Shaft diameter

|

70-80 mm

|

|

|

Machine body frame

|

350H steel

|

|

|

Roller material

|

Cr12

|

|

|

Machine size

|

About 6*1.5*1.2 m

|

|

|

Machine weight

|

4 - 6 tons

|

|

|

Machine color

|

As customer need

|

|

|

Working speed

|

12-60 m/min

|

|

Cutter |

Hardness

|

50-65 HRC

|

|

|

Cutting tolerance

|

± 1mm

|

|

|

Material

|

Cr12

|

|

|

Operate

|

Hydraulic cutting

|

|

Power |

Main motor

|

5.5 KW

|

|

|

Pump motor for cutter

|

7.5 KW

|

|

|

Voltage

|

380V/50HZ, 3P or Customized as customer' request

|

|

Control system |

PLC brand

|

Delta

|

|

|

Screen

|

Delta touch screen

|

|

|

Language

|

Chinese and English or add customer need language

|

Product Details

Packaging & Shipping

Why Choose Us

Hot Searches