4. If the raw material is in powder form, it can be made into granule directly; if the raw material is in granule form, it should be crushed into powder less than 3mm first.

5. Raw material moisture also has certain requirements, if less than 30%, it is better.

.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5-135KW

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

1360*980*2180mm

-

Type:

-

machine extruder dog food

-

Raw material:

-

carbon steel ,stainless steel

-

Capacity:

-

20-2000kg/h

-

Color:

-

customized

-

Pellet size:

-

0.8-12mm

-

Advantage:

-

electric heating or gas heating

-

Bearing:

-

NSK

-

Keywords:

-

Pet Snack Cat Dog Food Making Machine

-

Processing Types:

-

Twin Screw Extrusion machine

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Tianruo Machinery

-

Voltage:

-

220/380/410/440V

-

Power:

-

7.5-135KW

-

Weight:

-

800 KG

-

Dimension(L*W*H):

-

1360*980*2180mm

-

Type:

-

machine extruder dog food

-

Raw material:

-

carbon steel ,stainless steel

-

Capacity:

-

20-2000kg/h

-

Color:

-

customized

-

Pellet size:

-

0.8-12mm

-

Advantage:

-

electric heating or gas heating

-

Bearing:

-

NSK

-

Keywords:

-

Pet Snack Cat Dog Food Making Machine

-

Processing Types:

-

Twin Screw Extrusion machine

Products Description

DGP Series Floating Fish Feed Extruder Pelleting Machine

1.This fish feed extruder machine is pellet feed extrusion equipment. Fish food, cat food, dog food and other pet feed extruder. Various patterns can be produced, and the molds can be customized according to requirements.

2.The product discharge port is equipped with frequency conversion speed control rotary cutting device, which can be arbitrarily adjusted blade speed, control cutting speed and length

3.This equipment takes corn, soybean (bean cake) and other animal scraps as raw materials, which can be directly added to the machine to produce different pellets with novel shape, unique taste, rich nutrition and fine organization. Suitable for dogs, cats, fish, birds, rabbits, shrimps, etc.

Details Images

Product Paramenters

|

Model

|

Capacity

|

Power

|

Feed power

|

Pellet Size

|

Cut Power

|

Dimension

|

|

DGP-40

|

40-60kg/h

|

7.5kw

|

0.4kw

|

1-12 mm

|

0.4kw

|

1.25*1.03*1.3m

|

|

DGP-50

|

60-80kg/h

|

11kw

|

0.4kw

|

1-12 mm

|

0.4kw

|

1.28*1.03*1.2m

|

|

DGP-60

|

100-150kg/h

|

15kw

|

0.4kw

|

1-12 mm

|

0.4kw

|

1.45*0.95*1.5m

|

|

DGP-70

|

180-250kg/h

|

18.5kw

|

0.4kw

|

1-12 mm

|

0.4kw

|

1.6*1.4*1.45m

|

|

DGP-80

|

300-350kg/h

|

22kw

|

0.4kw

|

1-12 mm

|

0.6kw

|

1.87*1.4*1.5m

|

|

DGP-100

|

400-450kg/h

|

37kw

|

1.1kw

|

1-12 mm

|

0.6kw

|

1.7*2.3*1.4m

|

|

DGP-120

|

500-700kg/h

|

55kw

|

1.1kw

|

1-12 mm

|

1.5kw

|

2.2*2.9*1.2m

|

|

DGP-135

|

800-1000kg/h

|

75kw

|

1.1kw

|

1-12 mm

|

2.2kw

|

2.25*3.1*1.37m

|

|

DGP-160

|

1200-1500kg/h

|

90kw

|

1.5kw

|

1-12 mm

|

2.2kw

|

2.2*3.15*1.37m

|

|

DGP-200

|

1800-2000kg/h

|

132kw

|

1.5kw

|

1-12 mm

|

3.0kw

|

2.3*3.45*1.65m

|

Characteristic

①Mixing machine - →②Feed extruder . →③Stainless steel dryer - →④Anise seasoning machine

1. Put the well-proportioned raw materials and well-proportioned water into the mixer, and stir quickly and evenly

2. Put the mixed raw materials into the feeding hopper of the extruder, turn on the blanking device, temperature control, and cutter for extruding production.

3. Put the container under the discharge port of the extruder, and use the container to hold the semi-finished pellets

4. Put the semi-finished granules in the container into the hot air dryer, turn on the dryer, and dry evenly.

5. Put the dried semi-finished granules into the star anise seasoning machine, and add the well-proportioned animal fat for tumbling seasoning 6. After the seasoning is completed, pour out the particles, which is the finished product

Final Products

Raw materials

: Wheat meal, maize powder, soybean meal, cottonseed meal, fish meal, bone meal, corn meal, meat meal, etc.

Moisture of raw material:20%-25%

Oil content: ≤10%

Starch content: ≥30%

Raw material type: powder

Moisture of raw material:20%-25%

Oil content: ≤10%

Starch content: ≥30%

Raw material type: powder

Final Products

:

Fish feed, dog food, shrimp feed, frog feed, poultry feed, fox feed, textured soybean protein, etc.

Animal Feed Production Line

Mixer Machine--Fish feed extruder- Conveyor-- Dryer machine--Cooling conveyor --Seasoning machine-Packing machine

Floating Fish Feed Production Plant (Twin screw / Single Screw )

Function:

1).Various grains are used as raw materials to produce various shapes puffed food. It is a fully automatic production line.

2). Raw material: Corn flour, wheat flour, rice flour, bean flour and other grain powder as raw materials. And add a variety of nutrients and so on. (We can provide formula according to raw materials).

3). Final food: different shapes and sizes of corn puff snacks food, This production can also be used to produce dog food, cat food,shrimp feed,fish feed,poultry feed. Or produce corn flakes, baby food, etc by changing the mould and configuration.

4). Capacity: 100-150 kg/h,200-250 k/h,300-450 kg/h, 600-800 kg/h, 1 ton/h .

2). Raw material: Corn flour, wheat flour, rice flour, bean flour and other grain powder as raw materials. And add a variety of nutrients and so on. (We can provide formula according to raw materials).

3). Final food: different shapes and sizes of corn puff snacks food, This production can also be used to produce dog food, cat food,shrimp feed,fish feed,poultry feed. Or produce corn flakes, baby food, etc by changing the mould and configuration.

4). Capacity: 100-150 kg/h,200-250 k/h,300-450 kg/h, 600-800 kg/h, 1 ton/h .

1.Wet Type fish feed production line

it is equipped with a boiler which can continuously providing hot steam. It can produce all kinds of floating or sinking aqua feed for fish, shrimp, crab, loach, bullfrog, etc, and can produce many kinds of pet feeds for cat, dog, and etc. The pellet size can be from 0.9-15mm to feed different size fishes. High capacity and top quality products, our fish feed pellet machine is a preferred choice for medium or large size feed processing factory

and aquaculture farm.

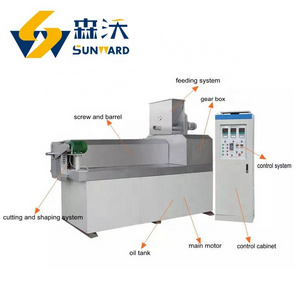

2.Twin Screw Extruder

It is composed of a feeding system, an extrusion system, a rotary cutting system, a heating system, a conveying system,and a control system.The material is conveyed, sheared, mixed and heated by the shell of the barrel, matured under the action of high temperature and high pressure,and then extruded out of the barrel. It is widely used in feed processing and can produce pet feed, aquatic feed, poultry feed.

DGP Series Fish Feed Pellet Machine.

Model:DGP-40 - Model:DGP-200

Feed extruder machine uses corn, soybean (bean cake) animal scraps, etc. as raw materials, and is suitable for the production of feed with different pet flavors such as dogs, cats, fish, birds, rabbits, shrimps, dogs, cats, minks, foxes, etc.

LX Series Pet Food Extruder Machine

Model:LX-45 -

Model:

LX-85

Dog food processing machines, fully automatic, high capacity and with different of shapes. It can be pet food

proccesing machine animal feed machine or poultry food machine , to produce such as cat food, dog food, fish food, bird food and so on

proccesing machine animal feed machine or poultry food machine , to produce such as cat food, dog food, fish food, bird food and so on

Floating Fish Feed extruder machine is suitable for farmers and small and medium-sized feed factories.The feed is neatly formed and smooth, it floats on the water surface without sinking for more than 12 hours, does not pollute water sources, and sterilizes to reduce fish diseases.

Floating aquarium fish feed pellet pet food making machine mainly use maize, fish powder, meat powder and some food additive as main raw material, through mixing, extruding, roasting, flavoring to get the final puffed pet food, so it also can be named dog food extruder.

Hot Searches