- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

az31 az63 MgMN HIGH POTENTIAL

-

Shape:

-

customized magnesium anode for CP Systerm

-

Material:

-

Magnesium Alloy Magnesium Alloy Sacrificial Anode, AZ63,Low potential mg anode Mg-Mn,high potential mg anode

-

Chemical Composition:

-

Magnesium Aluminum Zinc

-

name:

-

mg anodes for underground pipelines

-

Mg anode:

-

magnesium anode az63

-

Magnesium Anode:

-

cast Magnesium Anode Prepack Magnesium Anode, Magnesium Anode

-

MgMn Magnesium anode:

-

High Potential magnesium anode for cathodic protection

-

Magnesium anode az63:

-

Low potential(H1) magnesium anode for cathodic protection

-

Magnesium anode rod:

-

Heat water anode made by magnesium

-

magnesium anode rod:

-

Magnesium Anode for water heater

-

Sacrificial Magnesium Anode:

-

Prepack Magnesium Anode, Sacrificial Magnesium Anode

Quick Details

-

Application:

-

sacrificial anode for cathodic protection, Anti corrosion Magnesium Alloy Sacrificial Anode

-

Place of Origin:

-

Hunan, China

-

Brand Name:

-

HIGH BROAD Magnesium anode

-

Model Number:

-

az31 az63 MgMN HIGH POTENTIAL

-

Shape:

-

customized magnesium anode for CP Systerm

-

Material:

-

Magnesium Alloy Magnesium Alloy Sacrificial Anode, AZ63,Low potential mg anode Mg-Mn,high potential mg anode

-

Chemical Composition:

-

Magnesium Aluminum Zinc

-

name:

-

mg anodes for underground pipelines

-

Mg anode:

-

magnesium anode az63

-

Magnesium Anode:

-

cast Magnesium Anode Prepack Magnesium Anode, Magnesium Anode

-

MgMn Magnesium anode:

-

High Potential magnesium anode for cathodic protection

-

Magnesium anode az63:

-

Low potential(H1) magnesium anode for cathodic protection

-

Magnesium anode rod:

-

Heat water anode made by magnesium

-

magnesium anode rod:

-

Magnesium Anode for water heater

-

Sacrificial Magnesium Anode:

-

Prepack Magnesium Anode, Sacrificial Magnesium Anode

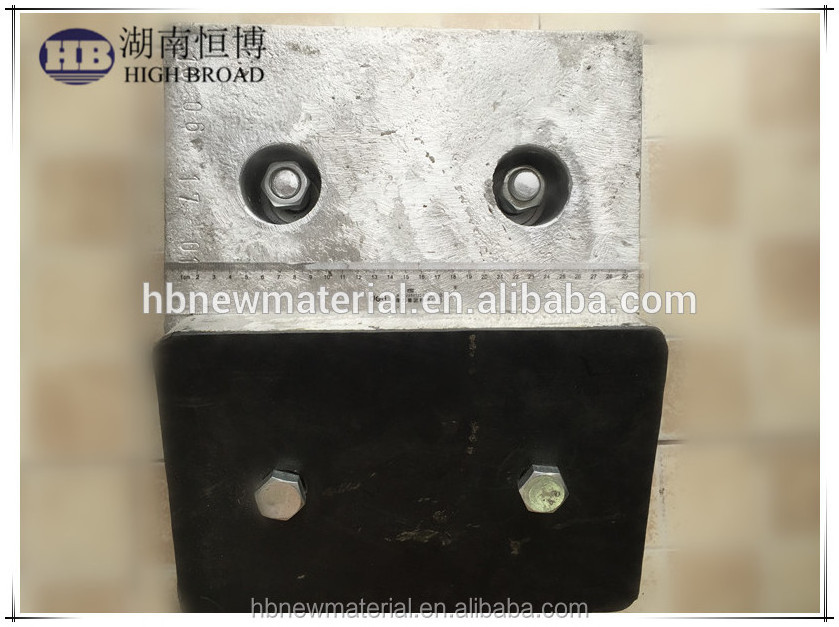

mg anodes for underground pipelines

Product details

| name | mg anodes for underground pipelines |

| Application | Anti corrosion Magnesium Alloy Sacrificial Anode |

| Mg anode | magnesium anode az63 |

| Magnesium Anode | cast Magnesium Anode Prepack Magnesium Anode, Magnesium Anode |

| MgMn Magnesium anode | High Potential magnesium anode for cathodic protection |

| Magnesium anode az63 | Low potential(H1) magnesium anode for cathodic protection |

| Magnesium anode rod | Heat water anode made by magnesium |

| magnesium anode rod | Magnesium Anode for water heater |

| Sacrificial Magnesium Anode | Prepack Magnesium Anode, Sacrificial Magnesium Anode |

| Material | AZ63,Low potential mg anode Mg-Mn,high potential mg anode |

| Product Keywords | mg anodes for underground pipelines |

Introduction: The corrosion of metal material in the intermediate of sea, lake or soil can be prevented by using the method of electro chemistry cathode protection. Magnesium anode is used in this method. Its theory is that connects the current of negative. Metal material or alloy with the protected metal body, with the exhausting and dissolving of negative metal material or alloy, protective current is transfused to protected metal body, this metal body will be protected from corrosion. It is widely used in ship building, port construction, sea work , under earth pipeline, petro chemical, electric powder, municipal affairs and other area.

According to the content of aluminum and zinc, the performance is different. Among them, the Mg-6Al-3Zn-Mn alloy has better performance and is widely used. Its surface dissolves uniformly and the current efficiency is greater than 50%. Aluminum is the main alloying element in the anode. , Can form Mg17 A112 strengthening phase with magnesium to improve the strength of the alloy. However, when aluminum is added to industrial magnesium alone, a large amount of Mg Al, Mg2A13, Mg4 A13 and other intermetallic compounds can be formed. The existence of these intermetallic compounds will increase the self-corrosion rate of magnesium and accelerate the destruction of solid solution. Zinc can reduce the corrosion rate of magnesium, reduce the negative difference effect of magnesium, and improve the anode current efficiency. A small amount of manganese can offset the adverse effects of impurity iron and nickel. When the amount of manganese added is 0.3%, the allowable iron content can reach 0.02%, but at the same time it will also reduce the current efficiency. Therefore, the content of impurity iron and the corresponding manganese content should be as low as possible. The simultaneous presence of aluminum, zinc, and manganese can further reduce the requirements for the content of impurity elements in industrial magnesium. In order to obtain good electrochemical performance, the impurity content of Mg-AI-Zn-Mn alloy should be strictly controlled. Under the conditions of similar alloy composition, the current efficiency of the alloy with less impurities is significantly higher than that of the alloy with more impurities.

|

Chemical compositions of cast magnesium anodes (%) |

||||

|

Element |

High potential |

AZ63B |

AZ63C |

AZ63D |

|

Al |

<0.01 |

5.30-6.70 |

5.30-6.70 |

5.0-7.0 |

|

Zn |

--- |

2.50-3.50 |

2.50-3.50 |

2.0-4.0 |

|

Mn |

0.5-1.30 |

0.15-0.70 |

0.15-0.07 |

0.15-0.70 |

|

Si (max) |

0.05 |

0.10 |

0.30 |

0.30 |

|

Cu (max) |

0.02 |

0.02 |

0.05 |

0.10 |

|

Ni (max) |

0.001 |

0.002 |

0.003 |

0.003 |

|

Fe (max) |

0.03 |

0.005 |

0.005 |

0.005 |

|

Others each |

0.05 |

--- |

-- |

--- |

|

Others total |

0.30 |

0.30 |

0.30 |

0.30 |

|

Mg |

Balance |

Balance |

Balance |

Balance |

|

Electrochemical Properties of cast magnesium anodes |

||||

|

Item |

Open-circuit Voltage |

Close-circuit Voltage |

Actual capacitance |

Current efficiency |

|

|

(-V) |

(-V) |

(A.h/g) |

(%) |

|

High Potential |

1.70-1.75 |

1.57-1.62 |

≥ 1.100 |

≥ 50 |

|

Low Potential (AZ63) |

1.50-1.55 |

1.45-1.50 |

≥ 1.105 |

≥ 50 |

|

Note: Open and Close-circuit voltage is relative to Saturated Calomel Electrode (SCE) |

||||