- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

XGZ-PEB255

-

Delivery Time:

-

45-60 days

-

Drawing design:

-

SAP2000/AutoCAD /PKPM /3D3S/TEKLA

-

Raw material:

-

Steel

-

Color:

-

Customized Color

-

Surface treatment:

-

Painted

-

Structure type:

-

Light Steel Structre

-

Certificate:

-

CE/ISO9001

-

Main frame:

-

Sqaure tube and H section steel

-

Wall&Roof panel:

-

Sandwich panel

-

Delivery time:

-

25-60 days

-

Life span:

-

50Years

Quick Details

-

Tolerance:

-

±1%

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XGZ

-

Model Number:

-

XGZ-PEB255

-

Delivery Time:

-

45-60 days

-

Drawing design:

-

SAP2000/AutoCAD /PKPM /3D3S/TEKLA

-

Raw material:

-

Steel

-

Color:

-

Customized Color

-

Surface treatment:

-

Painted

-

Structure type:

-

Light Steel Structre

-

Certificate:

-

CE/ISO9001

-

Main frame:

-

Sqaure tube and H section steel

-

Wall&Roof panel:

-

Sandwich panel

-

Delivery time:

-

25-60 days

-

Life span:

-

50Years

Products Description

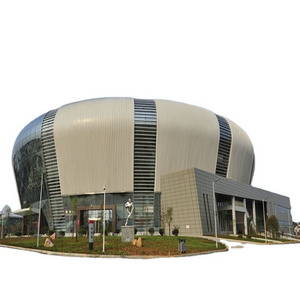

What is prefabricated steel structure building?

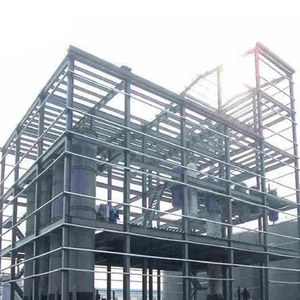

Steel structure building is built over three members connected to each other by bolts and screws:

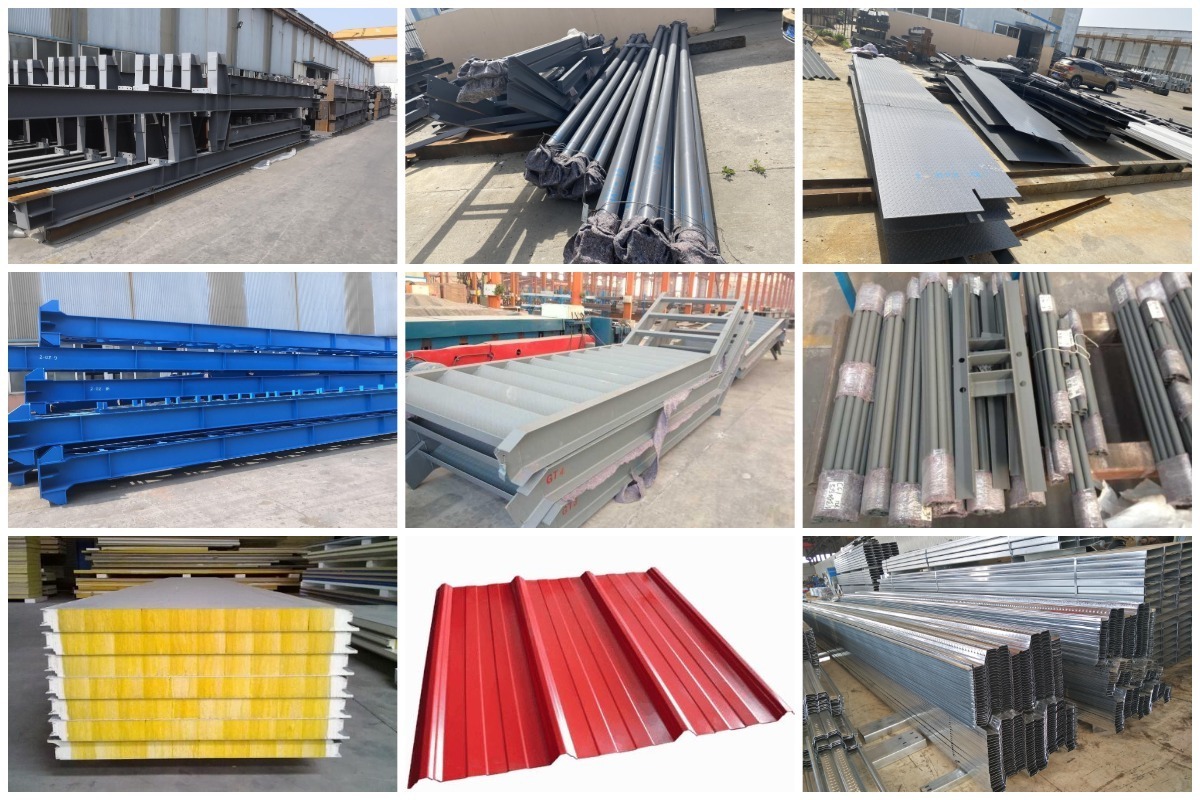

Primary members (columns, beams)

Steel columns will be H section steel, square tube steel according to different type of buildings. Steel beams are usually H section steel.

Secondary members (C or Z purlins, bracing...)

Roof and wall sheeting or sandwich panel (EPS, fiberglass wool, PU sandwich panel)

Other building components (Rolling doors, aluminium windows, etc.)

The entire primary members and secondary members are designed and fully fabricated including cut-to-length, punching, drilling, welding and performing in the factory before shipping to the site for erection.

At the site, all components are assembled and jointed via nut & bolt connections; thereby reducing the costs and assembly times.

These buildings can be provided with different structural and non-structural additions such as ventilators, doors & windows, trusses, mezzanine floors, canopies, crane, insulation…, based on the customer's requirements.

|

Steel structure office building

|

|

|

|

Item

|

Specification

|

|

|

Steel column

|

Q235,355B welded square tube column/Box column

|

|

|

Steel beam

|

Q235,355B welded H section steel/hot-rolled H section steel/steel truss

|

|

|

Steel purlin

|

C/Z section purlin or square tube

|

|

|

Downpipe

|

UPVC

|

|

|

Gutter

|

Stainless steel gutter/UPVC gutter

|

|

|

Roof material

|

Corrugated steel sheet/sandwich panel

|

|

|

Wall material

|

Sandwich panel and glass curtain wall

|

|

|

Door

|

Aluminium door

|

|

|

Window

|

Aluminium window

|

|

Compared with traditional concrete buildings, steel structure buildings use steel plates or section steel to replace reinforced concrete, which is stronger and more resistant to earthquakes. And because the component can be factory made, site installation, thus greatly reducing the construction period. Due to the reusable steel, it can be greatly reduced the construction waste, and more green environmental protection, so it is widely used in industrial buildings and civil buildings over the world.

If you want a building that has cost saving, fast erection, good quality control, high durability, steel structure buildings will be the best choice.

As the latest trend in building construction, steel structure buildings increasingly confirmed their outstanding advantages in agricultural, industrial and commercial projects such as workshop, warehouse, workshop, factory, storage, showroom, office building, supermarket, school, stadium, logistics center, etc…

Why choose steel structure buildings?

1. Cost Savings

Price per square meter can be 25% lower than conventional buildings. Site erection cost is low because of faster erection times and easier process.

2. Quality Control

Designed and fabricated in-factory with strict quality control. The fabrication process includes design and engineering, as well as detailing and manufacturing at the factory.

3. Quick Erection

All steel components are fabricated at the factory and linked by bolts at the site. So the erection process is fast, step by step, easy to install.

4. Flexibility

Steel buildings are flexible in any requirement of design, easy to expand in the future and also economically with low transportation costs.

5. Energy Efficiency

Nowadays, steel buildings are the green solution for the environment with CO2 reduction, energy efficiency, and recycle.

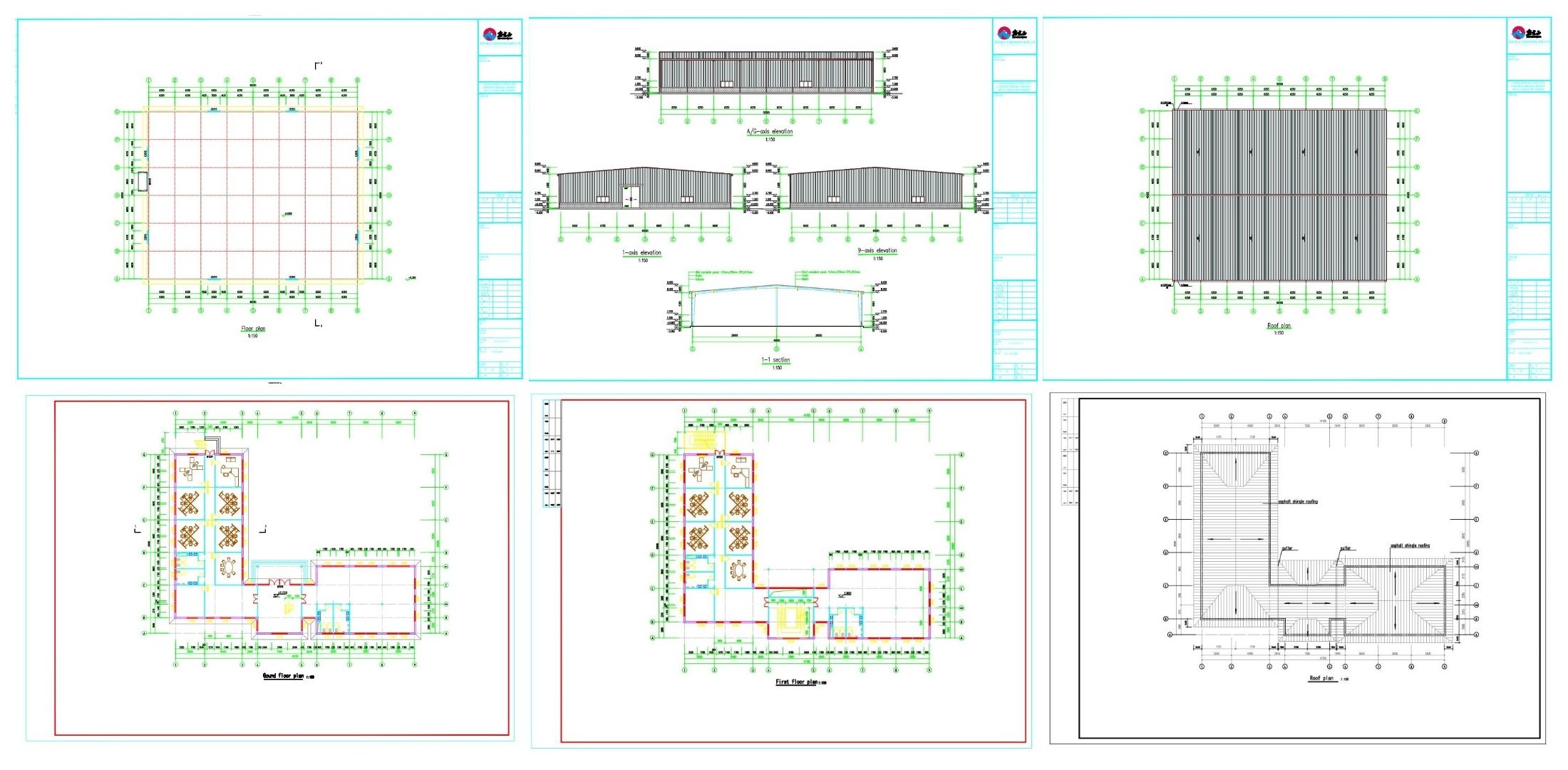

Design drawing

Tekla model

Installation of steel structure building

1.Foundation construction (pre-embedded anchor bolts), detail need to according to the foundation construction drawing.

2.Column installation

One worker commands truck crane how to move, 3 ~ 4 workers cooperate with crane to install the steel column, put column to anchor bolt location.

3.Beam installation

After completing the installation of adjacent two steel column, then main beam begin to install.

4.Installing roof & wall purlin

The roof and wall purlin will be installed after finishing column and beam. Bolting the purlin on the main structure.

5.Fixing wall and roof sheet

To fix the wall sheet on wall purlin by self-tapping screw; then fix the roof sheet.

6.Fixing the cover

To install the cover on the corner, eave, window and door opening.

7.Install windows and doors.

Product packaging

Customer Photos

Certifications

Exhibition

FAQ

Q: Are you trading company or manufacturer ?

A: We have our own steel structure, steel sheet and sandwich panel manufacturing factories. Welcome to our company to see our products and discuss your project.

Q: Can you provide on-site installation service? A: We can provide Installation guide service based on customers’ request. The shop drawing, installation drawing and video will send to client to help the site erection. If need, our engineer will come to site to guide the installation.

Q. What is the delivery time?

A: It depends on the quantities of order. Generally, the delivery time will be within 25 to 60 days.

A: We have our own steel structure, steel sheet and sandwich panel manufacturing factories. Welcome to our company to see our products and discuss your project.

Q: Can you provide on-site installation service? A: We can provide Installation guide service based on customers’ request. The shop drawing, installation drawing and video will send to client to help the site erection. If need, our engineer will come to site to guide the installation.

Q. What is the delivery time?

A: It depends on the quantities of order. Generally, the delivery time will be within 25 to 60 days.

Q. How can I get a quotation for my project?

A: Pls no hesitate to send me message here or Email me. I will reply to you ASAP. Welcome to contact me for your building!

A: Pls no hesitate to send me message here or Email me. I will reply to you ASAP. Welcome to contact me for your building!

Hot Searches