- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

200 mm

-

Width of Working Table (mm):

-

2600 mm

-

Dimension:

-

4000mm*1600mm*2600mm

-

Place of Origin:

-

ANHUI

-

Brand Name:

-

GENUO

-

Year:

-

2023

-

Weight (KG):

-

6000

-

Motor Power (kw):

-

7 kw

-

Marketing Type:

-

New Product 2023

-

Material:

-

Metal Steel Sheet

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Application:

-

Stainless Plate Bending

-

Keyword:

-

Hydraulic Press Break

-

Type:

-

Hydraulic Bending Tools

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Raw Material:

-

Steel Bar

-

Name:

-

Rebar Bending Machine

-

Function:

-

Sheet Metal Metal Bending

Quick Details

-

Machine Type:

-

bending machine

-

Length of Working Table (mm):

-

4000

-

Slider Stroke (mm):

-

200 mm

-

Throat Depth (mm):

-

200 mm

-

Width of Working Table (mm):

-

2600 mm

-

Dimension:

-

4000mm*1600mm*2600mm

-

Place of Origin:

-

ANHUI

-

Brand Name:

-

GENUO

-

Year:

-

2023

-

Weight (KG):

-

6000

-

Motor Power (kw):

-

7 kw

-

Marketing Type:

-

New Product 2023

-

Material:

-

Metal Steel Sheet

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Application:

-

Stainless Plate Bending

-

Keyword:

-

Hydraulic Press Break

-

Type:

-

Hydraulic Bending Tools

-

Usage:

-

Metal Sheet Rolling Cutting Bending

-

Raw Material:

-

Steel Bar

-

Name:

-

Rebar Bending Machine

-

Function:

-

Sheet Metal Metal Bending

Products Description

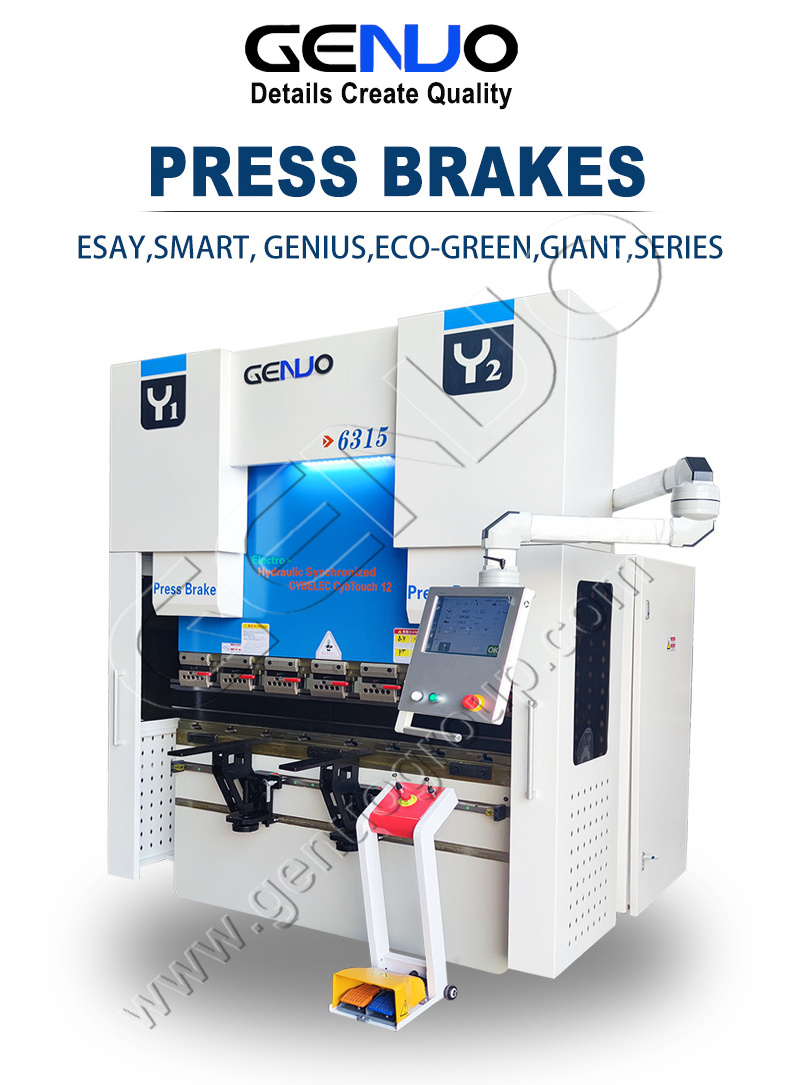

What make you get better production revenue in industry 4.0. GENUO press brakes do this by helping you to produce higher quality parts faster than ever and all with lower operating and maintenance costs. GENUO has a pressbrake to match your needs and budget whether your application requires bending complex parts or simple shapes.GENUO press brake have been designed to be precise,reliable,and high performing with easy operation.We have a solution for every manufacturing environmentand offer several models of press brakes with multiple features and options.Each of our press brake models have avariety of lengths and tonnages and can be customized for you.

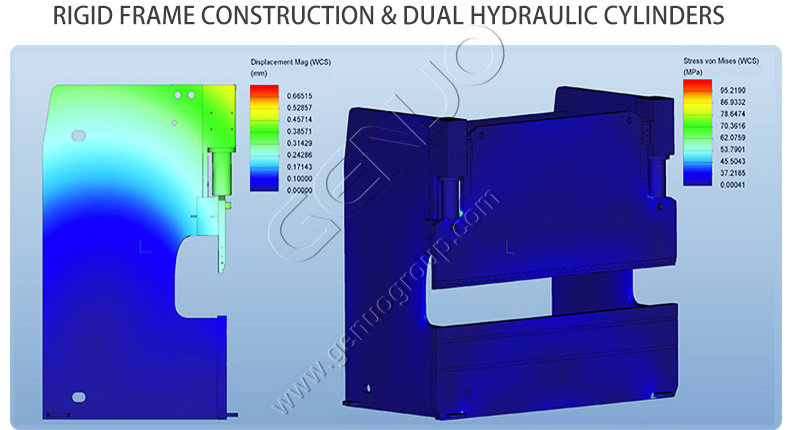

GENUO have vast experience with R&D and designing components to very tight tolerances with SOLIDWORKS ,CAD modelling techniques,and that CAE,ANSYS,SOLIDWORKS used as the method to analyze the linear static construction, stress and deformation for machine frames. So for complicated structures, highly complex loadings and transient modelling.The foundation of all GENUO press brakes is a solid,monoblock frame made from high-yield steel. Asa result, GENUO press brakes perform accurately and reliably year after year. We are so condent in our construction,we offer a 10-years frame warranty with our standard machines.

GENUO press brakes can easily accommodate parts with deep bends and that require long tooling because of our open space design.Our machines typically have deeper throat depths, larger daylight spaces and longer stroke lengths than most manufacturer in the market.We mounted the Ram guiding on the outside of the frame to maximize the distance between the side frames to accommodate deep part flanges.

DIVERSIFIED CONTROLLER

Delem DA-53T

“Hot-key”touch navigation with10.1"

wide screen high resolution colour TFT Up to 4 +1axes (Y1-Y2 , X, R(or Z)-axis and Crowning control).

Compact 4+1 axes touch colour CNC control for a wide range of press brake applications without compromising machine functionality.

Delem DA-58T

2D graphical touch screen programming with 15" high resolution colour TFT Bend sequence calculation and Crown

ing and Servo frequency control.

DA-58T provides CNC programming with 2D graphical product design tool.Minimize machine adjustments and test bending.

Delem DA-66T/69T

3D and 2D graphical touch screen programming with 17" high resolution colour TFT.Full Windows application suite.DA-66T is applicable to all synchronized series bending machines of GENIUS, ECO-

GREEN and GAINT. Up to 8+1 axes control (Y1-Y2 , X1, X2,R1,R2,Z1,Z2 and Crowning).

All GENUO's press brakes adopt world-class stable hydraulic system. To ensure the stable operation and lasting accuracy of the machine. At the same time, it also has its own hydraulic proportional synchronization technology, which can be develop and designed for different machines.

• Eco-friendly, saving 65% energy in comparison to standard press brakes. It also uses 95% less oil,which helps reduce manufacturing costs.

• Fast operating press brake using servo motors and highly effcient pump.

• Most accurate, having high bending accuracy between +/- .00003”

• Highest bending effciency is achieved and no pressure is lost through proportional valves.

• Quietest press brake, at a noise level of 63db. (TUV-SUD certifed)

• No oil heat up thanks to the pumping system which does not run when the machine is in stand-by mode.

• Provides fawless bending for small parts at different points.

• Ease of maintenance. Y1,Y2 axes have stand-alone oil tanks.

• Fast operating press brake using servo motors and highly effcient pump.

• Most accurate, having high bending accuracy between +/- .00003”

• Highest bending effciency is achieved and no pressure is lost through proportional valves.

• Quietest press brake, at a noise level of 63db. (TUV-SUD certifed)

• No oil heat up thanks to the pumping system which does not run when the machine is in stand-by mode.

• Provides fawless bending for small parts at different points.

• Ease of maintenance. Y1,Y2 axes have stand-alone oil tanks.

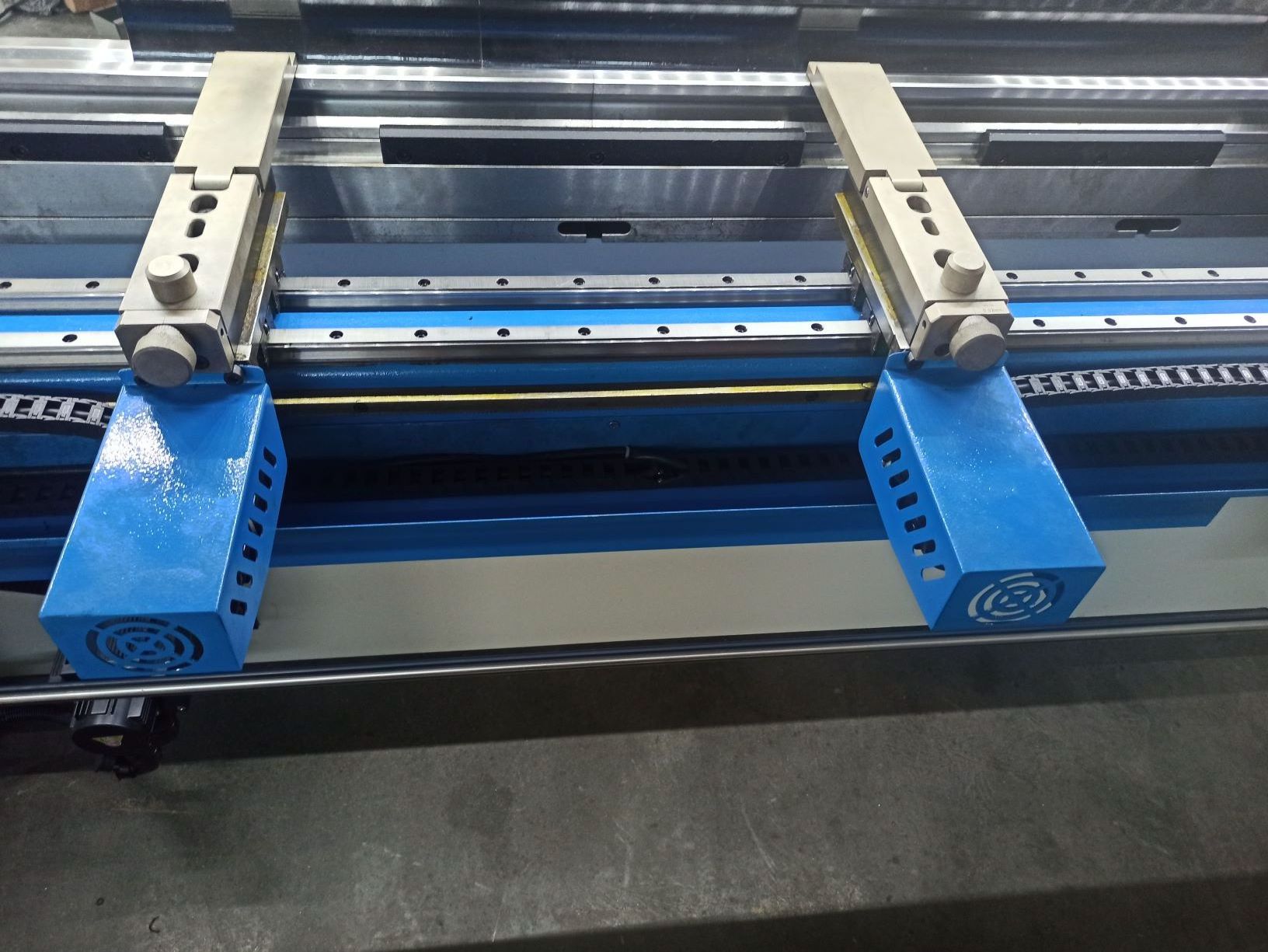

ACCURATE WITH HEAVY-DUTY BACKGAUGE

Establishing the right back gauge for your projects will allow for increased part

production and precision.From intricate parts which typically require more axes

to large quantities that require more time and therefore increased cost, the corr

ect back gauge for each job is essential to lowering costs per part which ultimately benefts your bottom line. GENUO technicians are happy to assist you with any questions you may have on your project requirements.

production and precision.From intricate parts which typically require more axes

to large quantities that require more time and therefore increased cost, the corr

ect back gauge for each job is essential to lowering costs per part which ultimately benefts your bottom line. GENUO technicians are happy to assist you with any questions you may have on your project requirements.

AUTO CROWNING SYSTEMS

To confrm a constant bend angle, manual or CNC crowning is essential which will

offset potential deviations and allow for possible tooling wear to maintain parallel

contacting surfaces.CNC crowning systems allow the press brake control to be pre

programmed with machine characteristics and defection data. Adjust the calculate

and setting accordingly for different characteristics and materials.

TOOLING AND CLAMPING

GENUO provides a variety of tooling solutions to meet your different production

needs. Not only that, we are also experts in the field of bending tools. If you have

any special bend, our engineers will customize special tools for each workpiece,

which greatly expands your press brake function and revenue. To help greatly

improve your productivity and business benefits.

In some tropical areas or uninterrupted operation is required, oil cooling device can be configured to avoid overheating of hydraulic oil and ensure continuous normal operation of the machine

Light Curtain Switch

The light curtain switch is applicable to some automatic factories to realize the regional management of machines.

Ensure that the machine is stopped when the operator checks and repairs the machine or appears in the wrong position. Improve safety.

DSP LASER protects the press brake operator from the danger of crushing that can take place accidentally between the moving part of the machine and the fixed one.

It assures to carry out the machine working cycle penalizing its execution time in the least.

Techical Specification

|

Model

|

Press Force

(mm)

|

Bend Length

(mm)

|

Inside Frame

(mm)

|

Throat Death

(mm)

|

|

HSC-40T/1600

|

400

|

1600

|

1250

|

300

|

|

HSC-63T/2500

|

630

|

2500

|

1960

|

320

|

|

HSC-100T/3200

|

1000

|

3200

|

2600

|

400

|

|

Back gauge Range

(mm)

|

Ram Strokes

(mm)

|

Max open

(mm)

|

Motor Power

(kw)

|

Dimension

L*W*H(mm)

|

|

10-500

|

150

|

420

|

4

|

1950*1750*2350

|

|

10-500

|

150

|

420

|

5.5

|

2850*1750*2350

|

|

10-500

|

150

|

480

|

7.5

|

3850*1850*2600

|

Hot Searches