● Sanitary food-grade stainless steel. Except motor part, all contact parts are made of stainless steel, especially both dynamic grinding disc and static grinding disc are reinforced, making them better properties of corrosion-resistance and wear-resistance. In that case, the finished materials are non-pollution and safe.

● Colloid mill is an ideal equipment for processing fine materials with features of compact design, elegant appearance, good seal, stable performance, easy operation and high production efficiency.

● The motor and the base are separate in the split colloid mill, ensuring good stability, easy operation and a long service life of motor, furthermore it avoids material leakage to prevent motor from burning. It employs labyrinth seal, no wear, corrosion-resistance and less failure. Driving by pulley, it can change gear ratio, increase speed and make materials crushed finely.

● The vertical colloid mill solves the problem that small colloid mills couldn’t work continuously for a long time due to insufficient power and poor sealing. The motor is 220V, its advantages include compact overall structure, small size, light weight, reliable sealing structure and long hours of continuous work, especially suitable for small businesses and laboratory.

● How to know the capacity of a colloid mill ? The flow varies greatly according to materials of different density and viscosity. For example the flow of viscous paint and thin dairy fluids can be different more than 10 times on the same colloid mill.

● Capacity depends on concentration and viscosity of materials ? A colloid mill mainly consists of a motor, grinding parts, driving and base part. Among them, dynamic grinding core and static grinding core are key parts. So you may need to choose different models according to nature of materials.

● Various colloid mill are small vibration, work smoothly and no need foundation.

- Product Details

- {{item.text}}

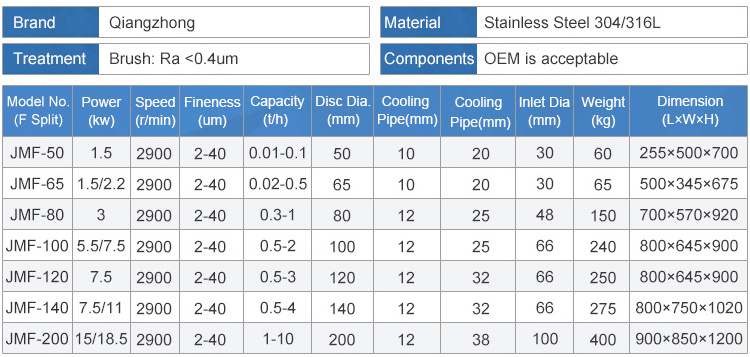

Quick Details

-

Machinery Function:

-

Grinder

-

Product name:

-

Colloid Mill

Quick Details

-

Weight (KG):

-

100

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Qiangzhong

-

Machinery Function:

-

Grinder

-

Product name:

-

Colloid Mill

Products Description

Features

1. Both rotor and stator are made of stainless steel, the rotor rotates at high speed and the stator keeps static, which makes materials passing the toothed bevel bear great force of shear and friction.

2. There is a pair of conical rotor and stator rotating at high speed inside a colloid mill. When materials pass the gap between the stator and rotor, they bear great force of shear, friction, centrifugal force and high-frequency vibration, finally making materials ground, emulsified, homogenized and dispersed.

3. It’s high efficiency of grinding ultra-fine particles by force of shear, grinding and high-speed stirring. And crush and grinding by relative movement of the disc tooth-shaped bevels.

4. Colloid Mill is an ideal wet-crushing equipment. Materials are ground, emulsified, crushed, mixed, dispersed and homogenized under forces of high-frequency vibration and high-speed vortex.

Note: The standard hopper capacity is 4 - 12 liters, and the customized capacity is acceptable.

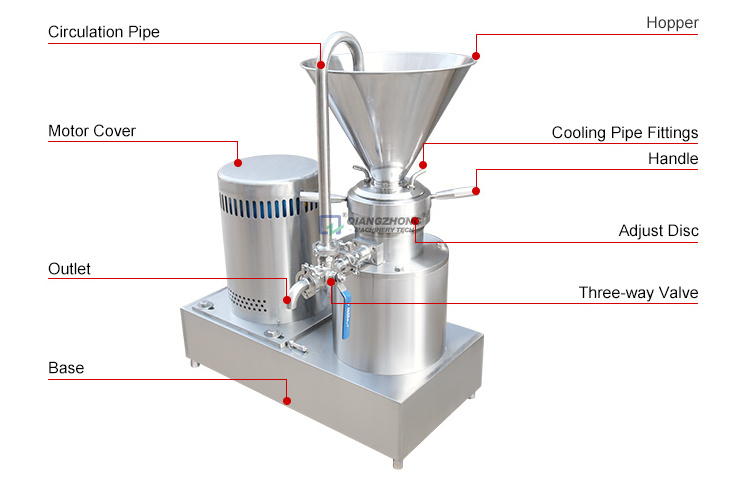

Circulation Pipe / Hopper

Stainless steel mill cores

Cooling Pipe Fittings / Adjust Disc

Internal structure

Quick connector / Outlet

Square outlet

Motor

Strengthen the base

Working Principle

The basic work principle of colloid mill is that fluid or semi-fluidmaterials pass the gap between fixed tooth and rotation tooth which are relative high-speed interlocking to make materials bear strong shearing force, frictional force and high-frequency vibration force. Grinding is by the relative motion of toothed bevels, one rotates at high speed, the other keeps static. In that case, materials passing the toothed bevels are greatly sheared and rubbed. At the same time, those materials are under forces of high-frequency vibration and high-speed vortex, which make them ground, emulsified, crushed, mixed, dispersed and homogenized, finally fine finished products are achieved.

Spiral Feeder:

For feeding materials of large particles to the mill disc.

Blade Feeder:

For fluid of small particles, semi-fluid

and emulsion materials.

Static Disc:

It makes materials greatly sheared and

rubbed when passing though toothed bevels

Rotation Disc:

Making materials effectively ground, emulsified,

Customer case

Advantages

|

Certification

|

25 National Patents, Audited by SGS/TUV/CE/ISO9001

|

|

Quality Guarantee

|

Complaint rate as low as 5‰ for 15 years. If you decide to purchase from us, any malfunction happened, once you enquiry us, we will reply you solution within 48 hours except the special reasons

|

|

Short Lead Time

|

Lead time is flexible. Short turnaround of replacement parts made by substantial storage, Normally we are 20% faster than others. If you have urgent orders, pls feel free to contact us. We will get the job done with 100% satisfaction.

|

|

24/7 Available

|

All your inquiry will be responded within 1 hour. All your quotation will be satisfied within 12 hours.

|

|

Why choose us?

|

•100% manufacturer

• Rich production experience •Strict Quality Control System •Flexible MOQ •Punctual delivery •Excellent and Experienced Team |

Hot Searches