- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

3PH~220V/380/415V~50HZ/60HZ

-

Dimension(L*W*H):

-

2200*1760*2200

-

Weight:

-

1750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Refrigerant:

-

R22/R404A

-

Compressor type:

-

semi-hermetic screw

-

Condenser:

-

aluminum finned copper tube + axil fan

-

Evaporator:

-

Shell and tube

-

Application:

-

vegetable, wine, seafood, meat, fruit refrigeration

-

Compressor brand:

-

BIZER, HANBELL,COPELAND

-

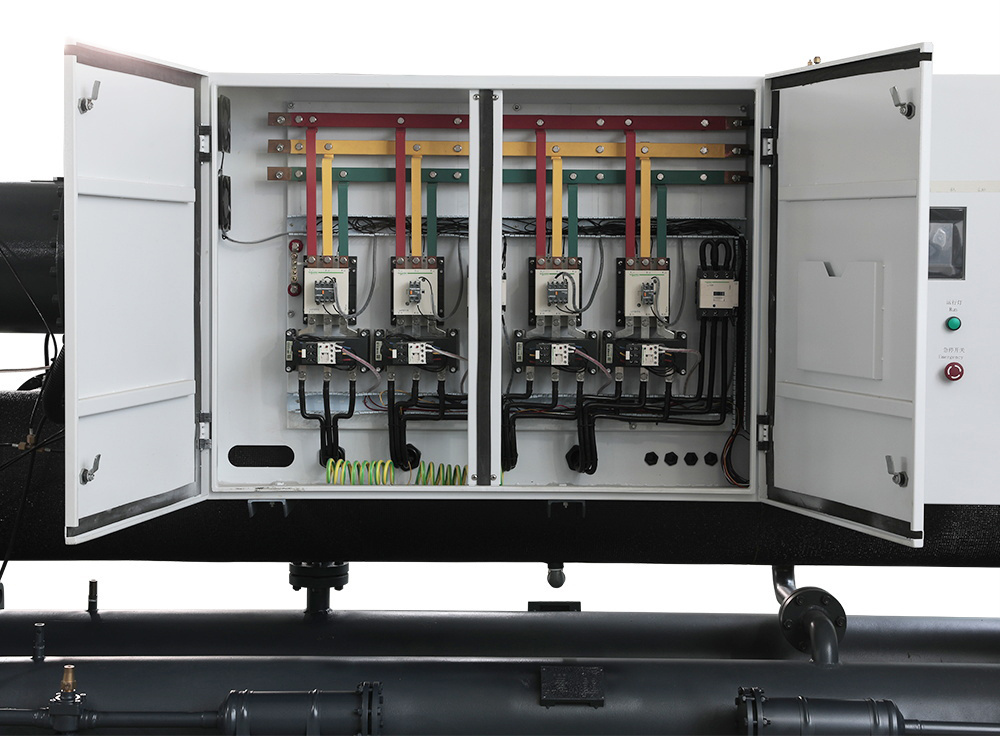

Electrical components:

-

Schneider

Quick Details

-

Condition:

-

NEW100%

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

HERO-TECH

-

Voltage:

-

3PH~220V/380/415V~50HZ/60HZ

-

Dimension(L*W*H):

-

2200*1760*2200

-

Weight:

-

1750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Refrigerant:

-

R22/R404A

-

Compressor type:

-

semi-hermetic screw

-

Condenser:

-

aluminum finned copper tube + axil fan

-

Evaporator:

-

Shell and tube

-

Application:

-

vegetable, wine, seafood, meat, fruit refrigeration

-

Compressor brand:

-

BIZER, HANBELL,COPELAND

-

Electrical components:

-

Schneider

HERO-TECH LOW TEMPERATURE SCREW CHILLER

HTSL series low temperature screw chiller is widely adopted in manufacturing process in industries such as non-ferrous smelting, chemical and pharmaceutical, petroleum chemistry, grain and oil, food and beverage, mechanical, electric, air separation, etc. Unit main parts include Semi-hermetic screw compressor, oil separator, condenser, economizer, evaporator and control system. If you have a need for reliable low-temperature cooling for your industrial application, we have the equipment you need. Our scroll chillers are currently used around the world to guarantee a vast range of processes for many leading companies. We can create custom chilling solutions adapted to your specific cooling needs and find ways to add value to your process with our reliable and efficient low-temperature scroll chillers.

HERO-TECH products are designed to help lower environmental impact with next-generation, low Global Warming Potential (GWP) refrigerants and high-efficiency operation.

Coolant temperature range from 5ºC to - 40ºC .

Adopt high efficient semi-hermetic twin-screw compressor , high COP steady performance and long service life.

Compressor stepped capacity control , minimize starting current and impact to grid.

25%-100% continuous capacity control , ensuring compressor full performance, saving running cost for customers.

Adopt high accuracy touch screen and imported PLC controller .

- Multi-protection function: compressor discharge over temperature, motor over temperature, anti-freezing, over current, phase sequence, high/low pressure, flow switch.

- Mass storage PLC, allows permanent reservation of more than 100 fault records, precisely monitors unit running state.

- Pass word setting , avoids unit from shut down or damaged by accidental factor.

- Control components including thermal expansion valve, solenoid valve, check valve are supplied by international brand , ensuring steady and efficient running under wide range of working condition.

Units are completely tested and operated at full load, leave factory with refrigerant, can be start once water and power is connected.

Compressor with built-in patented exhaust silencer ensures low noise running.

Corrosion-resistance water system could be designed upon request.

Refrigerant option: R22,R407C,R404A .

Dependable, versatile, high-efficiency cooling.

|

Model |

HTSL-50A |

|||

|

Nominal cooling capacity |

-10℃ |

kw |

93.5 |

|

|

-20℃ |

62.3 |

|||

|

-30℃ |

38.2 |

|||

|

Input power |

kw |

52.4 |

||

|

Power source |

|

3PH 380V~415V 50HZ/60HZ |

||

|

Refrigeration |

||||

|

Type |

|

R22/R404A |

||

|

Charge |

kg |

35 |

||

|

Control |

|

Thermostatic expansion valve |

||

|

Compressor |

||||

|

Type |

|

Semi-hermetic screw |

||

|

Motor power |

kw |

50 |

||

|

Start mode |

|

Staged start-up |

||

|

Capacity control |

% |

0-25-50-75-100 |

||

|

Evaporator |

||||

|

Type |

|

Shell and tube(ss plate heat exchanger) |

||

|

Chilled water volume |

-10℃ |

m³/h |

14.6 |

|

|

-20℃ |

9.6 |

|||

|

-30℃ |

7.2 |

|||

|

Water pressure drop |

kPa |

35 |

||

|

Pipe connection |

inch |

3 |

||

|

Condenser |

||||

|

Type |

|

Finned copper tube & big volume low noise axial fan |

||

|

Power |

kw |

0.6*4 |

||

|

Air volume |

m³/h |

37500 |

||

|

Safety devices |

Compressor inner protection, over current protection, high/low pressure protection, over temperature protection, flow rate protection, phase sequence/phase missing protection, low level coolant protection, anti freezing protection, exhaust overheat protection |

|||

|

Dimension |

Length |

mm |

2350 |

|

|

Width |

mm |

1800 |

||

|

Height |

mm |

2050 |

||

|

Net weight |

kg |

1650 |

||

|

Running weight |

kg |

1750 |

||

|

The above specifications are according to the following design conditions

|

||||

Food Processing

To guarantee the safety and consistent quality of frozen foods, food processing companies need low-temperature cooling day in and day out. Our low-temperature screw chillers have been put to the test in a range of food-related applications, including:

- Fast freezing of prepared food and meals

- Storage of food ingredients before use

- As part of disinfecting and antibacterial cleaning

Medical Processing

Certain medical fabrication processes and storage requires reliable cooling to guarantee safety and effectiveness. When cooling failure isn’t an option, you need a low-temperature scroll chiller you can count on for:

- Transforming various medical ingredients and compounds

- Manufacturing highly sensitive medicines

- Storage of medicines and human tissues for surgery

- Testing of new drugs and procedures in extreme cold conditions

Product and Material Testing

Many types of clothing, materials and equipment need to be tested to -35°C temperatures. Our low-temperature industrial scroll chillers can be used for a wide range of testing applications, such as:

- Automotive and transport equipment verification

- Fabric and cloth cold temperature resistance and protection

- Plastic, rubber and metal strength at freezing temperatures

- Cold temperature performance of coolants, oils and fluids