- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Lifeng

-

Model Number:

-

600

-

Voltage:

-

220V 50Hz

-

Dimension(L*W*H):

-

10000x2700x2000mm

-

Weight:

-

2000 KG

-

Product name:

-

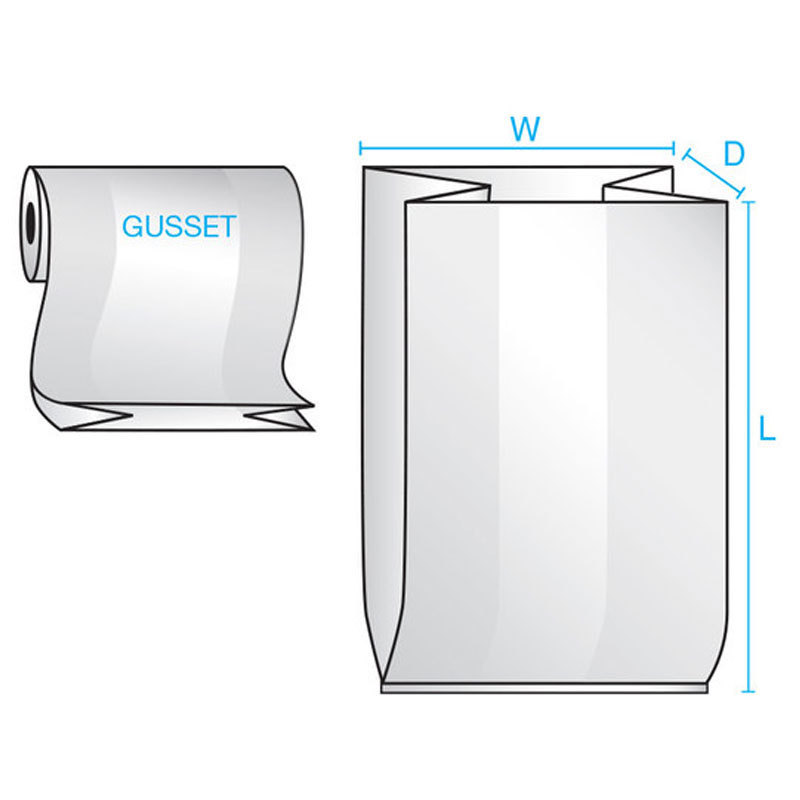

Gusseted Poly Bag rolling making machine

-

Type of bag:

-

PE Flat Bag

-

Suitable material:

-

LDPE HDPE Biodegradable Film

-

Servo motor:

-

Yaskawa

-

Bag Width:

-

200-580mm

-

Total power:

-

9.0kw

Quick Details

-

Machine Type:

-

Bag Forming Machine

-

Bag Type:

-

Shopping Bag

-

Material:

-

Plastic

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Lifeng

-

Model Number:

-

600

-

Voltage:

-

220V 50Hz

-

Dimension(L*W*H):

-

10000x2700x2000mm

-

Weight:

-

2000 KG

-

Product name:

-

Gusseted Poly Bag rolling making machine

-

Type of bag:

-

PE Flat Bag

-

Suitable material:

-

LDPE HDPE Biodegradable Film

-

Servo motor:

-

Yaskawa

-

Bag Width:

-

200-580mm

-

Total power:

-

9.0kw

Zhejiang Lifeng Machinery Co., Ltd,which has a long history, grand scale, self-research, sales service is professionally manufacturing plastic soft packaging machine with high technology.The quality of its products had firstly passed the certification of quality management system ISO9001-2008 and CE certification of European Union.

We are professional manufacture in kinds of Bag Making Machine,Film Blowing Machine,Printing Machine,Cutting Machine ,Recycle Machine,Plastic Air Bubble Film Machine,Laminating Machine,Slitting and Rewinding Machine are popular in all the markets of the whole world ,products are exported to eastern Europe,North America ,Southeast,Asia,Russia,Africa,Middle East and more than 20

countries and regions , They win good reaction in the market and welcomed by vast customers no matter new or old from home and abroad.

We are professional manufacture in kinds of Bag Making Machine,Film Blowing Machine,Printing Machine,Cutting Machine ,Recycle Machine,Plastic Air Bubble Film Machine,Laminating Machine,Slitting and Rewinding Machine are popular in all the markets of the whole world ,products are exported to eastern Europe,North America ,Southeast,Asia,Russia,Africa,Middle East and more than 20

countries and regions , They win good reaction in the market and welcomed by vast customers no matter new or old from home and abroad.

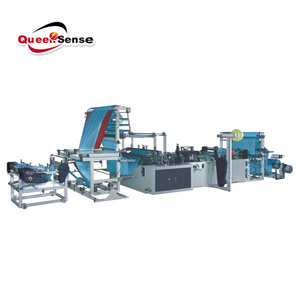

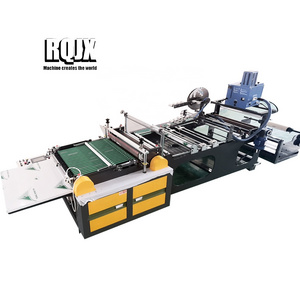

Machine Pictures

Automatic roll change continuous roll flat bag making machine

Products Description

Automatic roll change continuous roll flat bag making machine

This machine a specially-designed point-cut rolling dual-purpose for vest & flat bags,is controlled by a computer, the step(servo) setting length system reduces the sealing-cutting dimensions errors, and the installation of photoelectric eyes track help make the position of figure of printing bags accurately, the computer numerical control can be selected to adjust the length of bag the machine will automatically stop and sound a warning if there is something wrong.

This machine bag has automatic roll change function, which can save labor better

Use: The high and low density polyethylene film bags produced by the machine are applied to shopping in the supermarkets, shops and markets.

Performance and characteristics:

1. Computer automatic control, automatic counting and set counting alarm, high efficiency, saving manpower and time;

2. From film rolling to finished bag, it is fully automatic and one-time;

3. Domestic servo motor has fixed length, photoelectric tracking, accurate and stable, and photoelectric control is adopted for

feeding;

4. Adopt hot cutting device and intelligent temperature control system to make the bag mouth sealed firmly and smoothly;

5. The main engine adopts frequency converter to control speed regulation;

6. Rewinding is controlled by PLC;

7. Discharging is controlled by frequency converter;

1. Computer automatic control, automatic counting and set counting alarm, high efficiency, saving manpower and time;

2. From film rolling to finished bag, it is fully automatic and one-time;

3. Domestic servo motor has fixed length, photoelectric tracking, accurate and stable, and photoelectric control is adopted for

feeding;

4. Adopt hot cutting device and intelligent temperature control system to make the bag mouth sealed firmly and smoothly;

5. The main engine adopts frequency converter to control speed regulation;

6. Rewinding is controlled by PLC;

7. Discharging is controlled by frequency converter;

|

Model of machine

|

500*2

|

|

Speed of bag making

|

30-190 bags/min each lines

|

|

Max speed of film

|

120m/min

|

|

Length of bag making

|

100-900mm

|

|

Width of bag making

|

60-450mm

|

|

Thickness of bag making

|

0.005-0.015mm

|

|

Bag making methods

|

star sealing garbage bag

|

|

Control system of machine

|

Kailai PLC

|

|

Material feeding

|

4pcs of 370w AC motor with inverter control

|

|

Bag length control

|

2pcs of 2kw servo motor

|

|

Temperature control zones

|

solid relay heating

|

|

Temperature control precision

|

±2 0C

|

|

Heating power

|

2kw

|

|

Traction part

|

2pcs of 370w AC motor with inverter control

|

|

Power of winding motor

|

2pcs of 370w AC motor with inverter control

|

|

Turntable control

|

Reducer motor control

|

|

HMI

|

Touch screen control

|

|

Total power of machine

|

12kw

|

|

Dimension of machine

|

7800*1800*1800mm

|

Details Images

Which Bag do you want to produce

Our customer

Certifications

Packing & Shipping

FAQ

Q1:Are you a factory or trading company?

A1: We are established in 1995, a actual factory and manufacturer in the line of printing&package machine for 20 years.

Q2:Where is your factory located? How can I visit there?

A2: Our factory is located in Rui'an City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from

home or abroad, are warmly welcome to visit us!

Q3: Which industries are widely used in of your machine?

A3: Those are mainly used in making plastic bags and labels in the maket. Examples of stand up pouch, zipper pouch, plastic bag for dialy necessities and food, plastic label for drink bottle, Foil yogurt cup, Medical pouch, laminated film or soft carboard,etc.

Q4: How about the payment term?

A4: For new customer, our payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery.

Q5: What about your main market?

A5: Ourproducts be sold well in 30 provinces and have good reputation in China, also we pay attention on developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

Q6: How does your factory do regarding quality control?

A6: Quality is the most important principle. GREAT WALL people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed ISO and CE certification.

Q7:What about warranty and do the engineers available to overseas?

A7: One year warranty. During this period, if the machine has some problems, our engineers can go abroad to fix for you.

Q8:What about the service after sale?

A8: One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12hours and help you to slove the problem.

A1: We are established in 1995, a actual factory and manufacturer in the line of printing&package machine for 20 years.

Q2:Where is your factory located? How can I visit there?

A2: Our factory is located in Rui'an City, Zhejiang Province, China, about one hour by air from Shanghai. All our clients, from

home or abroad, are warmly welcome to visit us!

Q3: Which industries are widely used in of your machine?

A3: Those are mainly used in making plastic bags and labels in the maket. Examples of stand up pouch, zipper pouch, plastic bag for dialy necessities and food, plastic label for drink bottle, Foil yogurt cup, Medical pouch, laminated film or soft carboard,etc.

Q4: How about the payment term?

A4: For new customer, our payment terms is 30% T/T in advance before production, the balance 70% should be paid before delivery.

Q5: What about your main market?

A5: Ourproducts be sold well in 30 provinces and have good reputation in China, also we pay attention on developing the overseas market, such as Europe, Russia, Southeast Asia, Middle and South America, Africa, and other countries.

Q6: How does your factory do regarding quality control?

A6: Quality is the most important principle. GREAT WALL people always attach great importance to quality controlling from the very beginning to the very end. Our factory has passed ISO and CE certification.

Q7:What about warranty and do the engineers available to overseas?

A7: One year warranty. During this period, if the machine has some problems, our engineers can go abroad to fix for you.

Q8:What about the service after sale?

A8: One you have bought our machine, you can call us or email us telling us the machine problems and any questions about the machines. We will reply to you with 12hours and help you to slove the problem.

Hot Searches