Strengthening heat transfer, eliminating welding stress

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

4213x1960x2893MM

-

Weight:

-

9

-

Product name:

-

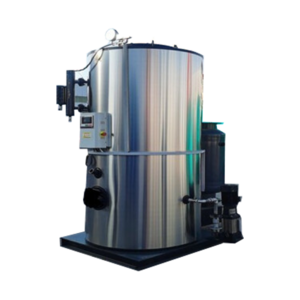

Coal wood industrial steam boiler china

-

Application:

-

Industrial Production

-

Capacity:

-

0.35mw to 2.8mw

-

Fuels:

-

coal wood

-

Stam temperature:

-

194

-

Warranty Period:

-

1 year

-

Heat efficient:

-

85%

-

Type of boiler:

-

Horizontal type boiler

-

Medium:

-

water

-

Application Field:

-

Papermaking Industry

Quick Details

-

Core Components:

-

FIRE TUBE

-

Steam Production:

-

0.35mw to 2.8mw

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Yongxing

-

Dimension(L*W*H):

-

4213x1960x2893MM

-

Weight:

-

9

-

Product name:

-

Coal wood industrial steam boiler china

-

Application:

-

Industrial Production

-

Capacity:

-

0.35mw to 2.8mw

-

Fuels:

-

coal wood

-

Stam temperature:

-

194

-

Warranty Period:

-

1 year

-

Heat efficient:

-

85%

-

Type of boiler:

-

Horizontal type boiler

-

Medium:

-

water

-

Application Field:

-

Papermaking Industry

1. Agriculture: Breeding, greenhouse planting, seed factory.

2. Chemical industry: Fertilizer Plant, refinery, feed factory, coating factory, plastic factory, glass factory.

3. Manufacturing: Paper Mill, textile factory, food factory, shoe factory, ceramic factory furniture factory.

4. Construction Industry: Highway Use, site use.

5. Others: Accommodation and catering, bath cente, hotel, disinfection of medical instruments and clothing.

3. Manufacturing: Paper Mill, textile factory, food factory, shoe factory, ceramic factory furniture factory.

4. Construction Industry: Highway Use, site use.

5. Others: Accommodation and catering, bath cente, hotel, disinfection of medical instruments and clothing.

|

Model

|

Rated Heat

Power

|

Rated Working

Pressure

|

Rated Outlet/Return

Temp

|

Heat

Efficiency

|

Design Fuel

|

Max Transport

Weight

|

Max Dimension

|

|

Unit

|

MW

|

Mpa

|

℃

|

%

|

|

kg

|

mm

|

|

DZH0.35-1.0/115/70-SCII

|

0.35

|

1.0

|

115/70

|

83

|

Coal

Biomass

Fuel

|

9000

|

3300x2000x2656

|

|

DZH0.7-1.0/115/70-SCII

|

0.7

|

|

|

|

|

13000

|

4820x2150x2960

|

|

DZH1.4-1.0/115/70-SCII

|

1.4

|

|

|

|

|

25000

|

5280x2380x3030

|

|

DZH2.1-1.0/115/70-SCII

|

2.1

|

|

|

|

|

26000

|

5500x2420x3250

|

|

DZH2.8-1.0/115/70-SCII

|

2.8

|

|

|

|

|

28000

|

6000x2500x3400

|

|

DZH4.2-1.0/115/70-SCII

|

4.2

|

|

|

|

|

30000

|

7200x2600x3800

|

|

Name

|

0.35-2.8mw coal pellet fired hot water boiler

|

|

Pressure

|

0.7Mpa-2.5Mpa

|

|

Fuel

|

Coal, Biomass pellet, Rice Husk, Bagasse, etc.

|

|

Capacity

|

0.35mw-2.8mw/h

|

Description:

DZH-Horizontal Automatic chain steam boiler, DZH series is single drum fire tube chain grate boiler.

Boiler main body is a single drum longitudinal layout. Drum and water tubes at both side forms radiation heating surface. Water tube forms convection surface. While threaded fire tube in the drum forms fire tube convection surface. Boiler consists of upper body and lower grates Which is combined at work site. Economizer is at the rear. Electric control cabinet can supervise the over temperature and lower. Pressure alarming and interlock protection, Which makes DZH series safe and reliable. Easy to operate.

Boiler main body is a single drum longitudinal layout. Drum and water tubes at both side forms radiation heating surface. Water tube forms convection surface. While threaded fire tube in the drum forms fire tube convection surface. Boiler consists of upper body and lower grates Which is combined at work site. Economizer is at the rear. Electric control cabinet can supervise the over temperature and lower. Pressure alarming and interlock protection, Which makes DZH series safe and reliable. Easy to operate.

Spirally corrugated tube

Wing Shape Flue

And three passes structure

And three passes structure

Reduce smoke temperature, prevent tube plate cracking, reduce heat load of boiler bottom and prevent bulge.

Moving grate

Moving grate Fuel feed manually, can be applied to multiple fuels, such as coal, wood logs, fire wood, biomass and other solid fuels.

2tph steam boiler in UZ

4tph diesle steam boiler in Kenya

25tph steam boiler in Myanmar

Vertical coal fired steam boiler in Chile

3mkcalph coal fired thermal oil boiler in Vietnam

2tph biomass boiler in Togo

1200kw diesel fired thermal oil boiler in Zimbabwe

2tph coal steam boiler in Philippines

10tph steam boiler in Ukraine

25tph coal fired steam boiler in Bangladesh

Electrical steam boiler in Ethiopia

2x12m wood treatment equipment in Zambia

Q1: What are the difference between vertical type boiler and horizontal type boiler withe the same capacity?

1) Structure of vertical boiler is compact ,occupy a litimited area. 2) Convenient on installation and removal.

3) Low cost and investment on capital construction. Steam exhausted fast and sufficient.

4) The combustion space of horizontal is4 big, fuel can be burned completed.

5) The thermal efficiency is higher than the vertical boiler.

6) Horizontal type: less thermal loss, stronger output, and higher steam quality.

Q2: What are the limitation (size, humidity, chemical element concentrations) of coal fuel/solid fuel/wood fuel?

Size requirement of coal:6-25mm

Size requirement of blending coal: <50mm (the coal less than 6mm should less than 30%)

Diameter of biomass particle: 6~10mm, length: 25~50mm, water content < 15%, ash content < 2%, sulphur content<0.07%, chlorinity <0.07%, nitrogen content < 0.5%

Q3: What is the size of furnace door and blower hopper?

Size of furnace door:

Standard elliptical furnace door:300*800*1500

Blower hopper size:

2 tons conical hopper: 1400*800*1500

4 tons conical hopper: 2200*1400*1500

Q4: What is the combustion mode of coal/biomass fired boiler?

The combustion mode of coal/biomass fired boiler is layer combustion. Place the flue on the fixed or moved grate, to form an evenly fuel bed with a certain thickness, air comes from the bottom of grate, and combustion occurred on the fuel bed.

1) Structure of vertical boiler is compact ,occupy a litimited area. 2) Convenient on installation and removal.

3) Low cost and investment on capital construction. Steam exhausted fast and sufficient.

4) The combustion space of horizontal is4 big, fuel can be burned completed.

5) The thermal efficiency is higher than the vertical boiler.

6) Horizontal type: less thermal loss, stronger output, and higher steam quality.

Q2: What are the limitation (size, humidity, chemical element concentrations) of coal fuel/solid fuel/wood fuel?

Size requirement of coal:6-25mm

Size requirement of blending coal: <50mm (the coal less than 6mm should less than 30%)

Diameter of biomass particle: 6~10mm, length: 25~50mm, water content < 15%, ash content < 2%, sulphur content<0.07%, chlorinity <0.07%, nitrogen content < 0.5%

Q3: What is the size of furnace door and blower hopper?

Size of furnace door:

Standard elliptical furnace door:300*800*1500

Blower hopper size:

2 tons conical hopper: 1400*800*1500

4 tons conical hopper: 2200*1400*1500

Q4: What is the combustion mode of coal/biomass fired boiler?

The combustion mode of coal/biomass fired boiler is layer combustion. Place the flue on the fixed or moved grate, to form an evenly fuel bed with a certain thickness, air comes from the bottom of grate, and combustion occurred on the fuel bed.

Hot Searches